Новости

Окончательное противостояние: Волоконный лазерный резак против. CO2 лазерный резак

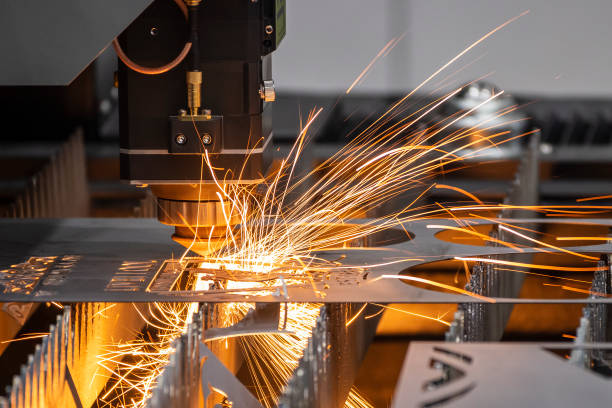

В быстро меняющемся мире производства, выбор между волоконный лазерный резак и лазерный резак CO2 может изменить игру. Представьте себе настолько точный инструмент, что он может прорезать металл, как горячий нож через масло, Создание сложных дизайнов с захватывающей дух скоростью и точностью. Правая технология лазерной резки может изменить вашу производственную линию, уменьшить отходы, и значительно улучшить вашу прибыль. Но какая технология царит высшим? В этом комплексном руководстве, Мы рассмотрим сильные и слабые стороны как волоконно -лазерных машин, так и лазерных резак CO2, Помогая принять обоснованное решение, которое продвинет ваш бизнес вперед.

1. Понимание основ лазерной резки

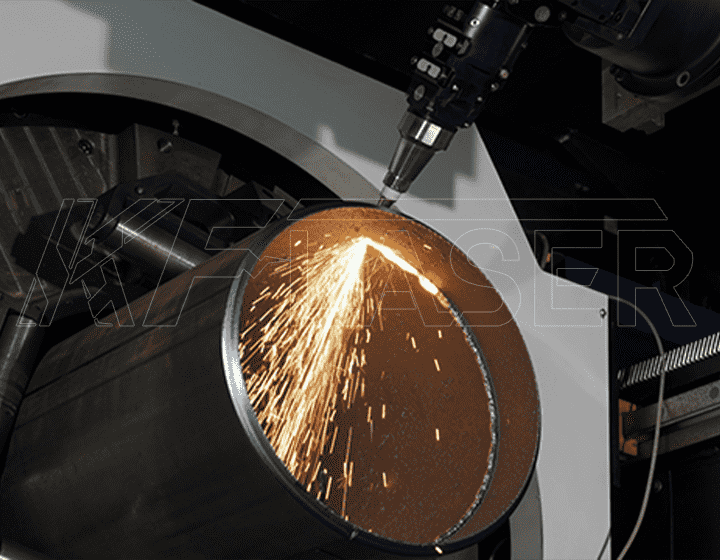

Прежде чем погрузиться в специфику, Крайне важно понять, что влечет за собой лазерная резка. Лазерная резка - это тепловой процесс, который использует сфокусированные лучи света для вырезания материалов. Используя высокоэнергетические лазеры, Производители могут достичь беспрецедентной точности, эффективность, и универсальность. Существует два основных типа лазеров, используемых для резки металла: волокно -лазеры и лазеры CO2.

- Что такое фантастика?

Фотоволоконная лазерная резак использует твердотельную лазерную технологию, которая использует оптические волокна для генерации и передачи лазерного луча. Этот тип режущей машины известен своей высокой эффективностью и способностью сократить широкий спектр материалов, в том числе металлы, такие как нержавеющая сталь, алюминий, и даже очень отражающие материалы, такие как медь.

- Что такое лазерный резак CO2?

Наоборот, Лазерный резак CO2 генерирует свой лазерный луч через газовую смесь, которая обычно включает углекислый газ, азот, и гелий. Эта технология существует дольше, чем лазеры из волокна и широко признается за универсальность в резании не только металлов, но и неметаллических материалов, таких как пластмассы и древесина.

2.Ключевые различия между лазерными резаками волокна и CO2

Понимание нюансов каждой технологии необходимо для выбора информированного выбора. Вот некоторые критические различия между волоконно -лазерными машинами и лазерами CO2:

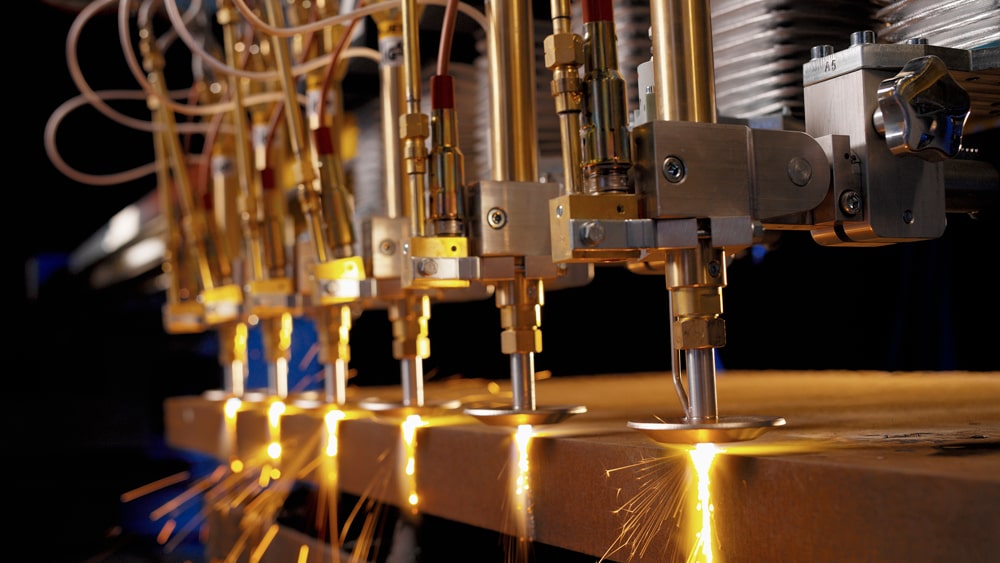

- Эффективность и энергопотребление

Волоконные лазеры известны своей энергоэффективностью. Они обычно потребляют меньше мощности по сравнению с лазерами CO2, обеспечивая равные или превосходные скорости резки. Это делает волокнистые лазерные машины для резки..

Факт: Лазерный резак для волокна может сокращаться на скорости в пять раз быстрее, чем лазер CO2, Особенно при резке более тонких материалов.

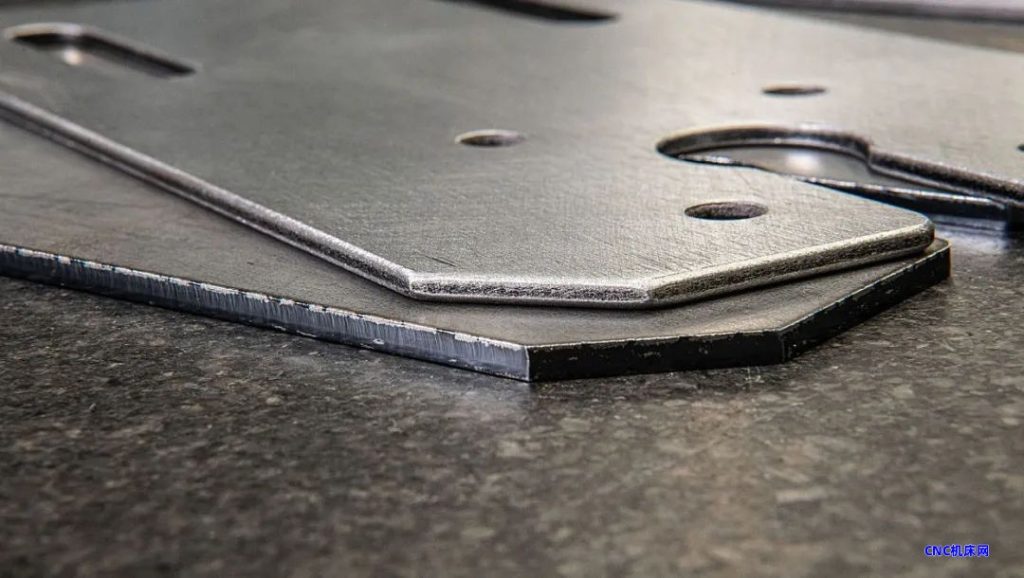

- Скорость и качество резки

Когда дело доходит до скорости, волоконные лазеры иметь четкое преимущество, Особенно с более тонкими материалами. Они достигают более быстрой скорости резания из -за своей меньшей длины волны, который обеспечивает лучшее поглощение в материал. Это приводит к более плавным краям и уменьшенным зонам нагрева, Минимизация искажения материала.

Кончик: Если ваше производство включает в себя сложные конструкции или большую резку тонких металлов, Фоторий -лазерный резак, вероятно, является превосходным выбором.

- Материальная универсальность

Лазеры CO2 отмечаются за их способность разрезать различные материалы, в том числе неметалы. Однако, волоконные лазеры добились значительных успехов в резке как отражающих, так и нерефлексивных металлов. Они преуспевают в режущих материалах, которые сложны для лазеров CO2, такие как медь и латунь.

Рекомендация: Если ваши операции включают в себя разнообразные материалы, Важно оценить конкретные потребности вашей производственной линии, прежде чем сделать выбор.

- Техническое обслуживание и продолжительность жизни

Одним из заметных преимуществ лазеров волокон является их более низкие требования к обслуживанию. В отличие от лазеров CO2, которые полагаются на зеркала и линзы, которые требуют регулярной очистки и выравнивания, Клетчатые лазеры более просты и имеют меньше компонентов, подверженных износу. Это переводится на меньшее время простоя и снижение эксплуатационных расходов.

Наблюдение: Инвестиции в лазерный резак для волокна могут привести к значительной экономии с течением времени из -за его долговечности и более низких потребностей в техническом обслуживании.

- Первоначальные инвестиции и рентабельность инвестиций

В то время как лазеры CO2 могут иметь более низкие первоначальные цены на покупку, Общая стоимость владения может быть выше из -за потребления энергии и обслуживания. Волоконные лазеры, хотя потенциально более дорогие аванс, может обеспечить лучшую отдачу от инвестиций (Рентабельность) В долгосрочной перспективе из -за их эффективности и низких эксплуатационных расходов.

3.Приложения и варианты использования отрасли

Как волоконно -лазерные машины, так и лазеры CO2 обнаружили применение в различных отраслях промышленности, Но лучший выбор часто зависит от конкретных требований каждого сектора.

- Автоматизированная индустрия

В автомобильном секторе, Точность и скорость имеют решающее значение. Лазеры волокна все больше предпочтительны для резки панелей тела, рамки, и замысловатые детали из -за их превосходной скорости и чистых краев резки. СО2-лазеры, Пока все еще используется, чаще используются для неметаллических частей и прототипирования.

- Аэрокосмическая промышленность

Аэрокосмическая промышленность требует самых высоких уровней точности и минимального веса. Лазеры из волокна идеально подходят для обрезки легких сплавов и сложных компонентов, Обеспечение того, чтобы детали соответствовали строгим стандартам безопасности и производительности.

- Производство медицинского оборудования

Для производства медицинских устройств, где гигиена и точность имеют первостепенное значение, Лазеры из волокна предпочтительнее для их способности создавать беззаребные порезы. Также можно использовать лазеры CO2, но, как правило, менее эффективны для резки металла в этом применении.

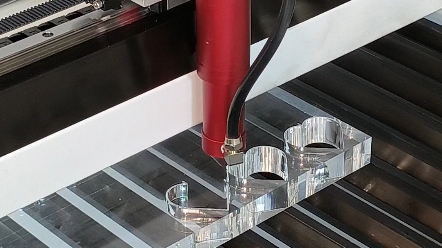

- Искусство и декоративная промышленность

Оба типа лазеров широко используются в художественных приложениях. Волокнистые лазеры преуспевают при запутанных металлоконтражах, Позволяя художникам создавать подробные скульптуры и инсталляции. Лазеры CO2 часто используются для резки неметаллических материалов, таких как древесина и акрил для декоративных целей.

4.Факторы, которые следует учитывать при выборе между лазерными резаками для волокна и CO2

При выборе между волоконно -лазерной режущей машиной и лазерным резаком CO2, Рассмотрим следующие факторы, чтобы убедиться, что вы делаете правильный выбор:

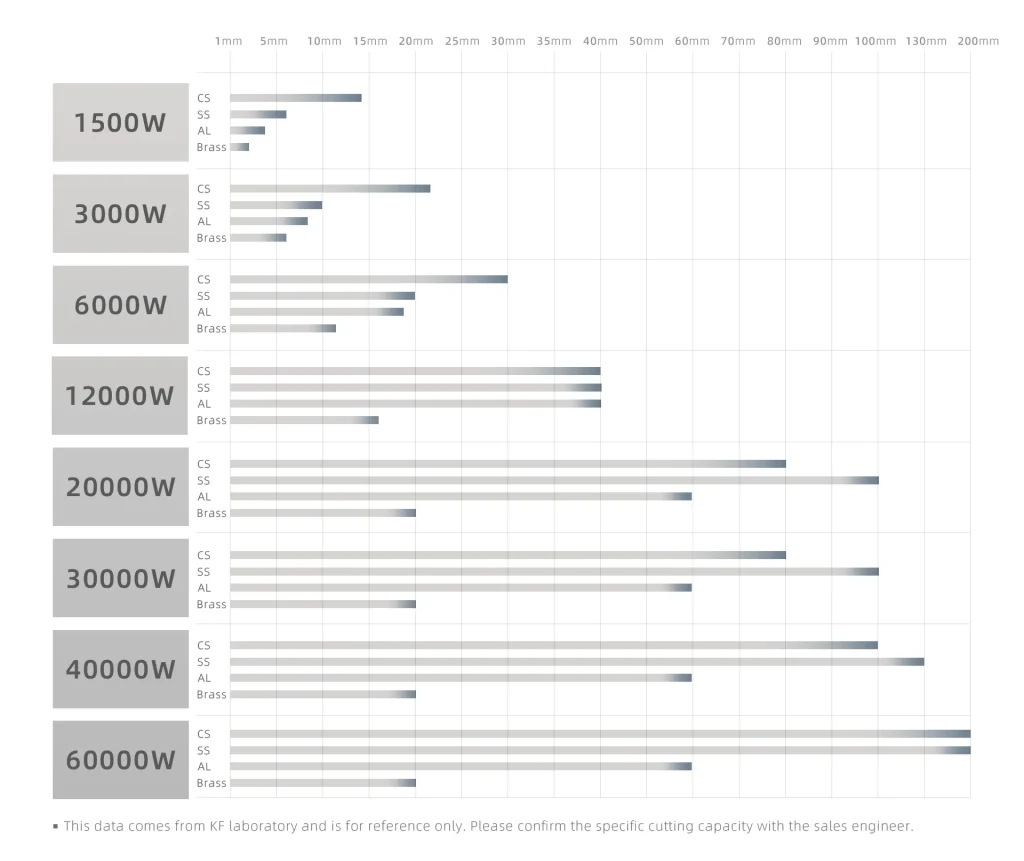

- Типы материалов и толщины

Оцените типы материалов, которые вы будете резать, и их толщины. Если ваше внимание сосредоточено в первую очередь на металлах, особенно отражающие, Лазер волокна часто является лучшим выбором. Для более широкого спектра материалов, в том числе пластмассы и дерево, Лазеры CO2 могут быть более подходящими.

- Производственный объем и скорость

Если ваши операции требуют высокоскоростной резки, особенно для более тонких материалов, волокнистые лазеры могут значительно увеличить пропускную способность. Наоборот, Если ваши потребности включают в себя более толстые материалы или различные неметаллические субстраты, Лазеры CO2 могут предложить преимущества.

- Бюджет и общая стоимость владения

В то время как волокнистые лазеры могут иметь более высокую начальную стоимость, Рассмотрим долгосрочную экономию энергии и технического обслуживания. Оцените свой бюджет не только для самой машины, но и для эксплуатационных расходов с течением времени.

- Будущий рост и гибкость

Рассмотрим свои долгосрочные производственные цели. Если вы планируете расширить ассортимент материалов или увеличить объем производства, инвестиции в станок для резки волоконным лазером могут обеспечить гибкость, необходимую для адаптации к меняющимся требованиям..

5. Вердикт: Что лучше?

В конечном счете, Решение между лазерным резаком и лазерным резаком CO2 зависит от ваших конкретных потребностей и оперативных требований. Для высокоскоростной, Точная резка металлов, особенно отражающие материалы, волокнистые лазеры явно затмевают их аналоги CO2. Однако, Если ваши приложения охватывают более широкий спектр материалов, в том числе неметалы, Лазеры CO2 по -прежнему имеют значительную ценность.

В КФ ЛАЗЕР, Мы предоставляем комплексные идеи и первоклассные варианты оборудования, чтобы помочь вам выбрать лучшее решение для лазерного резки для вашего бизнеса. Оценивая ваши производственные требования, Бюджетные ограничения, и долгосрочные цели, Вы можете принять обоснованное решение, которое улучшит ваши производственные процессы и улучшит вашу прибыль.

Выбор между волоконно -лазерной режущей машиной и лазерным резаком CO2 - это больше, чем просто техническое решение; Это стратегический, который может повлиять на эффективность производства и качество продукции на долгие годы. Понимая различия, преимущества, и конкретные применения каждой технологии, Вы можете выбрать правильное решение для лазерной резки, которое соответствует вашим операционным потребностям и позиционирует ваш бизнес для успеха. Независимо от того, резаете ли вы металлы для автомобильной промышленности или создаете сложные дизайны для декоративных целей, Правый лазерный резак может иметь все значение в достижении совершенства.

Главные новости

-

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025 -

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025 -

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025 -

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025 -

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина