Notícias

Acidentes de máquina de corte a laser de fibra: Compreendendo os riscos e protocolos de segurança

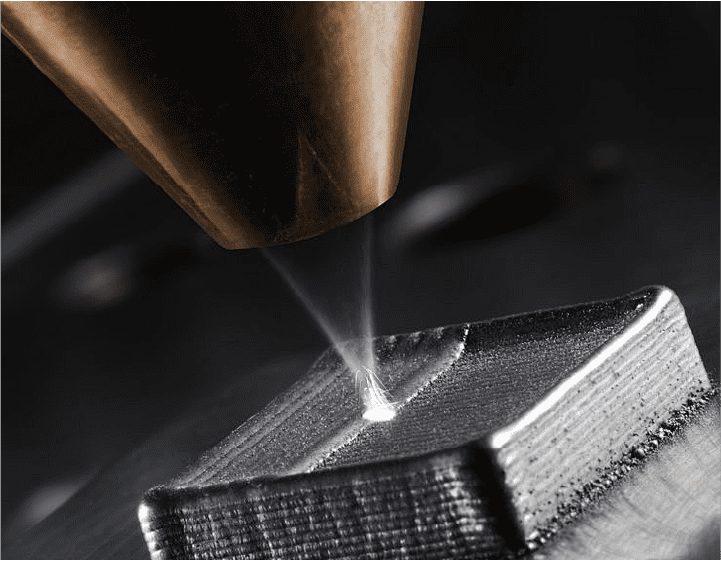

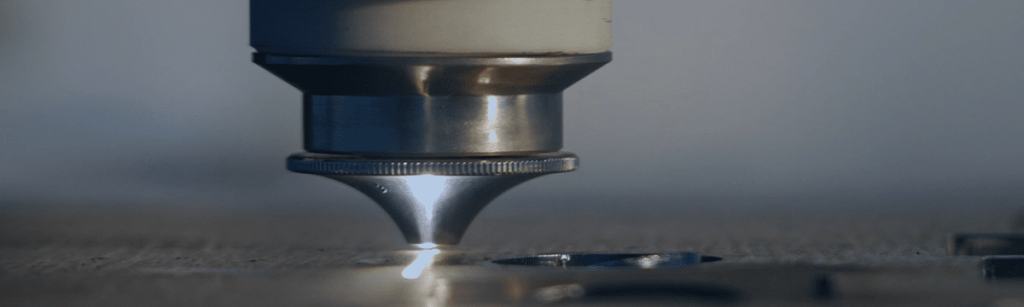

Em indústrias que dependem máquinas de corte a laser de fibra, Acidentes podem representar riscos significativos para operadores e equipamentos. Enquanto os lasers de fibra são conhecidos por sua eficiência, precisão, e versatilidade, operação inadequada, falta de treinamento, e medidas de segurança inadequadas podem levar a acidentes que resultam em lesões, dano, ou tempo de inatividade.

Compreendendo as causas comuns de acidentes de máquina de corte a laser de fibra e a implementação de protocolos de segurança é essencial para criar um ambiente de trabalho mais seguro. Neste artigo, discutiremos as causas comuns desses acidentes, como eles podem ser evitados, e as melhores práticas de segurança para garantir a longevidade da segurança do operador e do equipamento.

Causas comuns de acidentes com máquina de corte a laser de fibra

Máquinas de corte a laser de fibra são peças sofisticadas de equipamentos que exigem operação e manutenção cuidadosas. Acidentes podem acontecer por vários motivos, variando de erro do operador à falha mecânica. Vamos explorar algumas das causas mais comuns de acidentes:

1. Falta de treinamento do operador

Uma das principais causas de acidentes nas operações de corte a laser de fibra é o treinamento inadequado. Os operadores que não são treinados adequadamente podem cometer erros na configuração da máquina, operação, ou solução de problemas, aumentando a probabilidade de acidentes.

Fatores de risco:

- Calibração ou configurações incorretas da máquina.

- Falha em entender os recursos de segurança e procedimentos de emergência.

- Falta de conhecimento sobre manuseio de materiais e parâmetros de corte.

Prevenção:

- Programas de treinamento abrangentes que cobrem a operação da máquina, Procedimentos de segurança, e solução de problemas.

- Cursos regulares de atualização de segurança para operadores existentes.

- Treinamento prático com cenários do mundo real para preparar operadores para situações de emergência

2. Manutenção inadequada da máquina

Como qualquer equipamento industrial, máquinas de corte a laser de fibra requer manutenção regular para garantir uma operação segura e eficiente. A falha em manter a máquina adequadamente pode levar a mau funcionamento mecânico, como superaquecimento, Surimentos de energia, ou falha de peças, tudo isso pode causar acidentes.

Fatores de risco:

- Desgaste em componentes críticos, como a cabeça do laser, motores, ou óptica.

- Acumulação de detritos ou poeira na área de corte.

- Falha em substituir as peças desgastadas no tempo.

Prevenção:

- Estabelecer um cronograma de manutenção regular com base nas recomendações do fabricante.

- Inspecione componentes críticos como a óptica a laser, sistema de resfriamento, e fonte de alimentação regularmente.

- Mantenha a área de trabalho limpa para impedir que os detritos interfiram no desempenho da máquina.

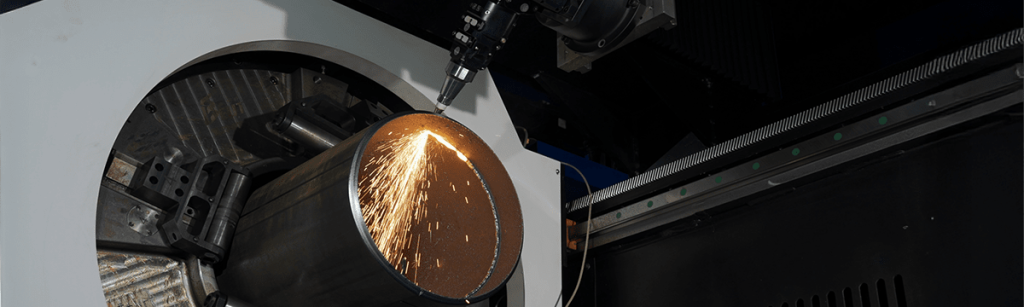

3. Mal equipamentos de segurança e meio ambiente

Acidentes podem ocorrer se o equipamento de segurança correto não for usado ou se o ambiente ao redor da máquina de corte a laser for perigoso. Os lasers de fibra geram feixes de luz de alta intensidade que podem causar queimaduras graves ou danos oculares. Adicionalmente, O processo de corte gera calor, fumaça, e faíscas, o que pode levar a incêndios ou explosões se as devidas precauções não estiverem no lugar.

Fatores de risco:

- Ausência de óculos protetores para operadores.

- Sistemas inadequados de ventilação ou extração de fumaça.

- Falta de extintores de incêndio ou barreiras de segurança ao redor da máquina.

Prevenção:

- Certifique -se de que todos os operadores se desgasçam apropriados óculos de segurança a laser Projetado para comprimentos de onda a laser de fibra.

- Instale os sistemas de ventilação adequados para remover vapores e gases nocivos da área de corte.

- Coloque os extintores de incêndio perto da máquina e garanta que os operadores sejam treinados para usá -los em caso de incêndio.

- Use barreiras de segurança ou escudos para proteger os operadores e outros funcionários da exposição a laser.

4. Manuseio incorreto de materiais

O manuseio inadequado de materiais durante o processo de corte pode levar a acidentes. Por exemplo, Se o material não estiver posicionado corretamente na cama de corte ou se materiais incompatíveis forem usados, Pode resultar em falhas, cortes irregulares, ou até ejeção de material, que poderia prejudicar o operador.

Fatores de risco:

- Materiais de Materiais Integidamente Seguros ou Desalinhados.

- Usando o tipo de material errado para as configurações específicas de laser.

- Materiais de manuseio com as mãos nuas ou sem luvas adequadas.

Prevenção:

- Verifique se os materiais estão posicionados e alinhados com segurança na cama de corte.

- Sempre verifique se o tipo de material corresponde às configurações de energia a laser, velocidade, e foco.

- Use luvas de proteção ao manusear materiais para evitar queimaduras ou lesões de bordas afiadas.

Prevenção de acidentes de máquina de corte a laser de fibra: Medidas de segurança

Prevenindo acidentes de máquina de corte a laser de fibra envolve uma combinação de treinamento adequado, manutenção regular, Equipamento de segurança correto, e aderência estrita aos procedimentos operacionais. Aqui estão algumas medidas de segurança importantes para implementar:

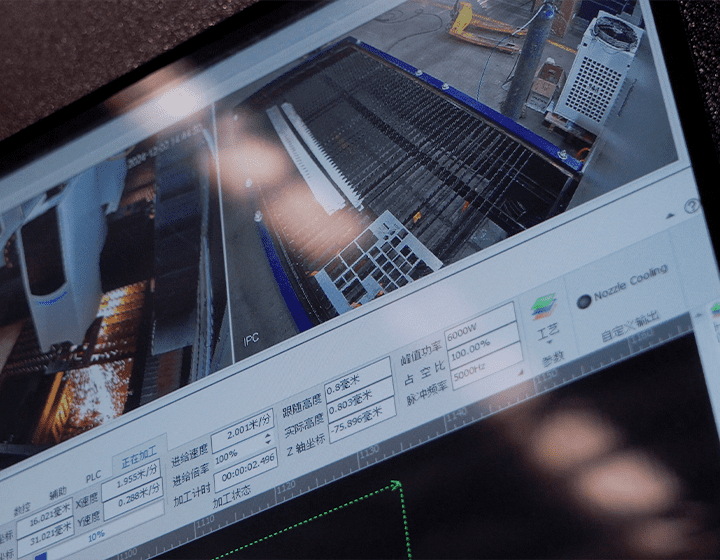

1. Inspeções regulares de segurança

Realize inspeções de segurança completas da máquina e do ambiente de trabalho antes de cada turno. Certifique -se de que todos os recursos de segurança, como botões de parada de emergência, intertravamentos de segurança, e escudos protetores, estão funcionando corretamente.

2. Uso de equipamento de segurança a laser

Os operadores devem sempre usar óculos de segurança a laser projetados especificamente para comprimentos de onda a laser de fibra. Esses óculos protegerão seus olhos da radiação prejudicial a laser. Adicionalmente, Roupas de proteção, como luvas e aventais resistentes à chama, podem impedir queimaduras de materiais quentes ou faíscas.

3. Implementando procedimentos operacionais padrão (POPS)

Estabelecer procedimentos operacionais padrão claros e abrangentes (POPS) para operar o máquina de corte a laser de fibra. Os POPs devem cobrir tudo, desde a configuração da máquina até o manuseio de materiais e as ações de resposta a emergências. Os operadores devem seguir estritamente esses procedimentos para minimizar os riscos.

4. Estabelecendo um programa de manutenção robusto

Um programa de manutenção bem estruturado é essencial para prevenir falhas de equipamentos. Limpe regularmente a óptica a laser, Verifique o sistema de refrigeração, Inspecione as partes móveis, e substitua os componentes desgastados. Manter a máquina em estado superior reduzirá significativamente as chances de mau funcionamento e acidentes subsequentes.

5. Treinamento e educação contínua

O treinamento deve estar em andamento para manter os operadores atualizados sobre os mais recentes protocolos de segurança e funcionalidades da máquina. Até operadores experientes podem se beneficiar de cursos de atualização que reforçam as melhores práticas de segurança. Uma força de trabalho treinada tem menos probabilidade de cometer erros que podem levar a acidentes.

6. Preparação de emergência

Acidentes ainda podem acontecer, apesar das melhores precauções. É importante ter um plano claro de resposta a emergência em vigor. Todos os operadores devem saber como desligar rapidamente a máquina em caso de emergência, E eles devem estar familiarizados com os procedimentos de primeiros socorros para queimaduras ou outros ferimentos.

Conclusão

Máquinas de corte a laser de fibra são ferramentas poderosas que oferecem precisão e eficiência, Mas com o poder vem o potencial de acidentes. Ao entender as causas comuns de acidentes de máquina de corte a laser de fibra e implementar medidas preventivas, você pode reduzir o risco de lesão e danos. Concentre -se no treinamento do operador, manutenção adequada, e adesão aos protocolos de segurança para criar um ambiente de trabalho seguro. Lembrar, A segurança não é apenas um requisito - é uma responsabilidade que garante a operação suave e eficiente de seus processos de corte.

Notícias principais

-

6 kw laser cutting | Industrial precision guide28 novembro 2025

6 kw laser cutting | Industrial precision guide28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025 -

4kw de espessura de corte a laser | Capacidade máxima de material18 novembro 2025

4kw de espessura de corte a laser | Capacidade máxima de material18 novembro 2025 -

Máquina de corte de chapa metálica para venda: Ultimate Buyer's Guide14 novembro 2025

Máquina de corte de chapa metálica para venda: Ultimate Buyer's Guide14 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa