Notícias

Máquina de corte de metal a laser de fibra: O futuro da tecnologia de corte de metal

The fiber laser metal cutting machine has swiftly become one of the most sought-after innovations in the field of metal fabrication. With the demand for high precision, velocidade, and cost-efficiency in industries ranging from automotive to aerospace, fiber laser cutting has proven to be a game changer. This cutting-edge technology ensures that metal cutting is not only faster but also more accurate, leading to superior end products with minimal waste.

1. What is a Fiber Laser Metal Cutting Machine?

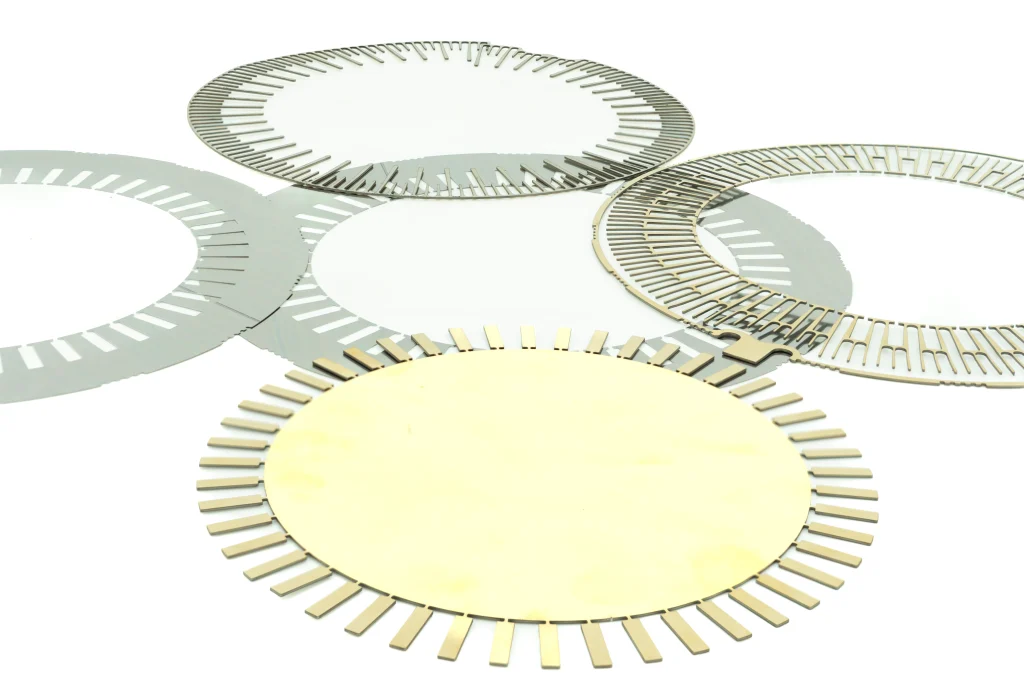

UM fiber laser metal cutting machine uses a fiber laser to focus intense light energy onto a metal surface, cutting through it with precision. The core mechanism relies on the fiber laser, which has a solid-state optical fiber as the medium that generates the laser beam. This method allows for clean, precise cuts in various metals, incluindo aço, aço inoxidável, e alumínio.

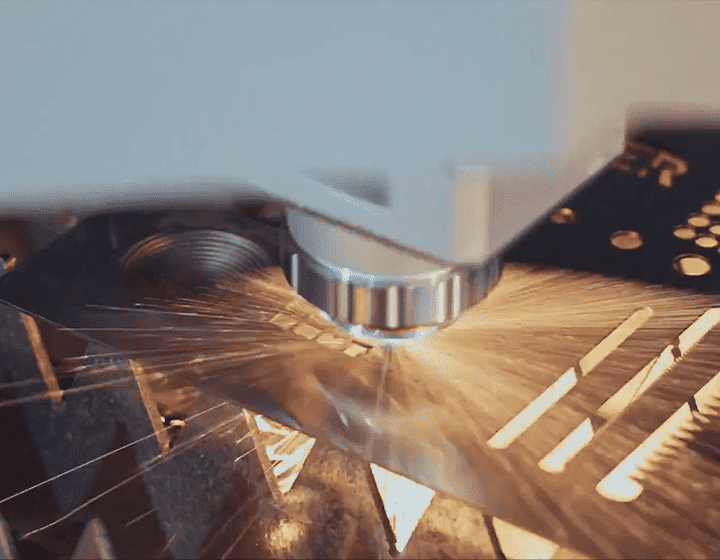

◆ How Does It Work?

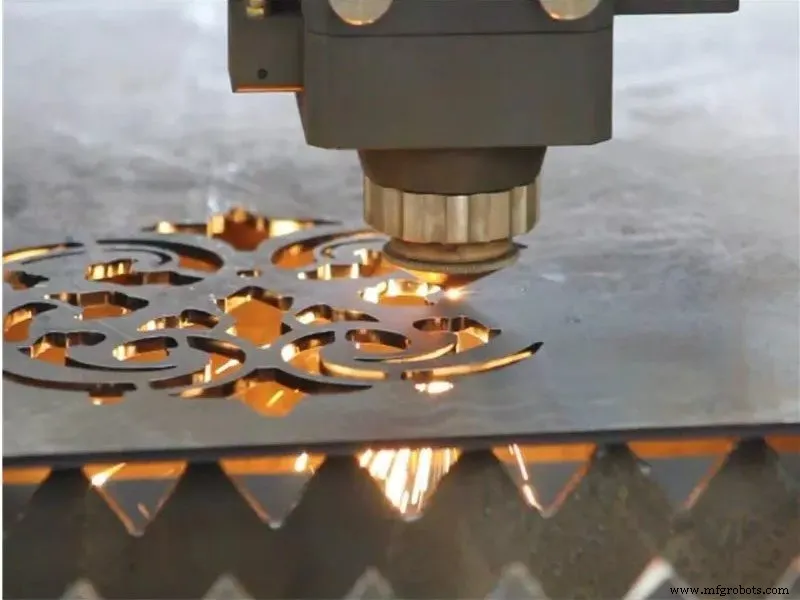

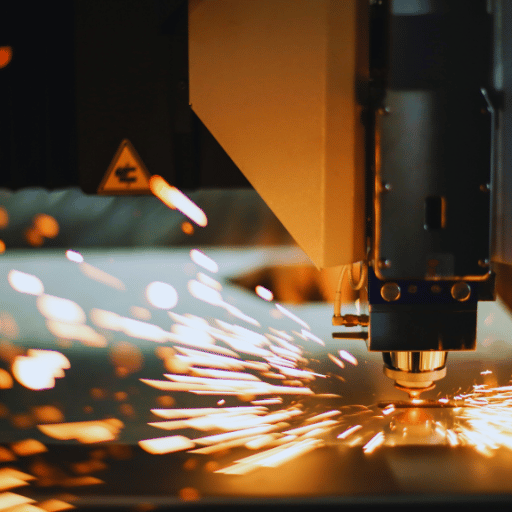

The process begins when the fiber laser generates a high-powered beam of light, which is directed onto the metal surface. The focused laser beam melts the material, and the molten metal is then blown away by a high-pressure gas, leaving behind a clean cut. The precision of the fiber laser cutting machine ensures that each cut is accurate to the micron, making it ideal for intricate and complex designs.

▶ The video below may help you understand the working principle of the laser cutting machine more intuitively.

2. Advantages of Using a Fiber Laser Metal Cutting Machine

There are several distinct advantages to using a fiber laser for cutting metal, particularly in industries where high-quality fabrication is critical. Let’s explore the top reasons why fiber laser cutting machines are becoming the standard in modern manufacturing.

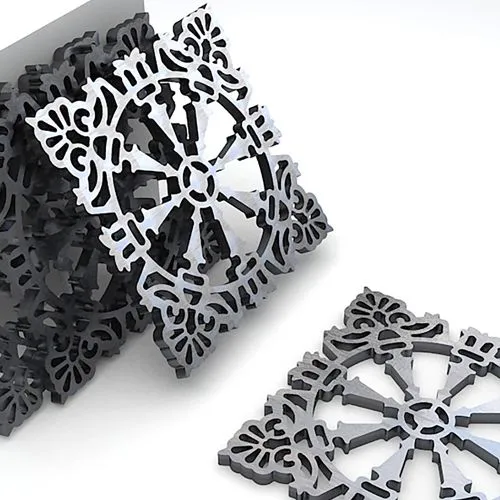

◆ Superior Precision

The accuracy provided by fiber laser metal cutting machines is unmatched. These machines can cut metal sheets and plates to an extremely high tolerance, making them perfect for applications where minute details matter. Whether it’s intricate patterns or precise edge finishes, fiber laser technology delivers results that are far superior to other methods like plasma or waterjet cutting.

◆ Speed and Efficiency

Fiber lasers cut at impressive speeds, dramatically increasing production efficiency. Unlike traditional cutting methods that require longer set-up times, fiber laser systems are quicker to start and more efficient in their operation. The high-powered laser can slice through even thick metal sheets, while the high-speed processing ensures shorter cycle times and faster delivery of finished products.

◆ Low Maintenance Costs

Compared to other types of laser cutting machines, fiber lasers have lower maintenance costs due to fewer moving parts and no need for reflective mirrors. This makes them more reliable and cost-effective over the long term. The solid-state nature of fiber lasers reduces the likelihood of failure and decreases the frequency of repairs, saving businesses money.

◆ High Power Output with Low Energy Consumption

One of the most significant benefits of a fiber laser metal cutting machine is its power efficiency. The fiber laser’s solid-state design allows it to operate with minimal power loss, making it more energy-efficient than CO2 lasers. The energy savings are not only beneficial for reducing operational costs but also for creating a more environmentally friendly manufacturing process.

3. Comparison of Fiber Laser Cutting vs. Corte a laser CO2

While both fiber and CO2 lasers are commonly used for cutting metals, there are important differences between the two technologies.

◆ Speed and Efficiency

Fiber laser machines are generally faster than CO2 lasers. The high beam quality of fiber lasers, coupled with their ability to maintain a tighter focus, results in faster cutting speeds, particularly for thinner materials. Lasers de CO2, por outro lado, may struggle with thinner metals and often require more time to achieve the same cutting speeds.

◆ Cost Efficiency

Fiber lasers have a lower cost of operation compared to CO2 lasers, thanks to their energy efficiency and lower maintenance costs. Although the initial investment for fiber laser systems may be higher, the long-term savings in power and maintenance make them a more cost-effective choice for many manufacturers.

◆ Versatility

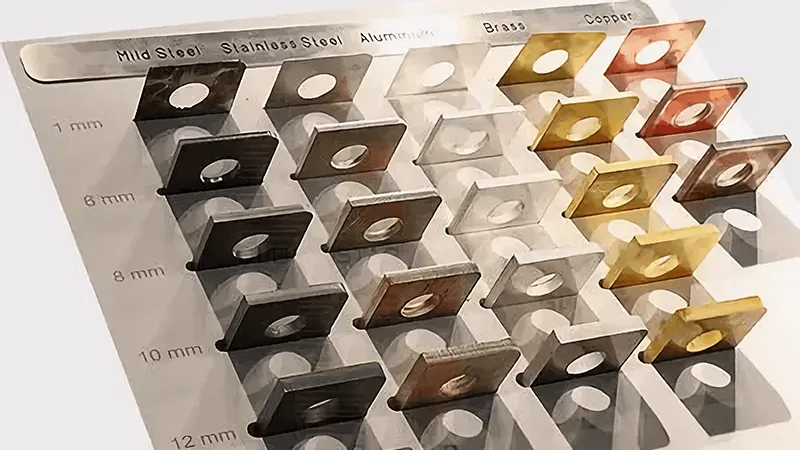

Fiber lasers excel at cutting a wide range of metals, including reflective materials like copper and brass, which are challenging for CO2 lasers. Fiber lasers can easily handle materials that CO2 lasers find difficult to cut, making them more versatile in terms of the types of metals they can process.

4. Applications of Fiber Laser Metal Cutting Machines

The versatility of fiber laser metal cutting machines makes them invaluable across a variety of industries, incluindo automotivo, aeroespacial, médico, e mais. Below are just a few examples of how these machines are transforming industries.

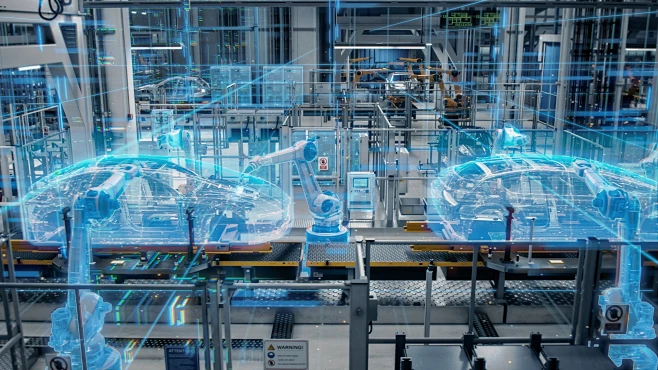

◆ Automotive Industry

Na indústria automotiva, fiber laser cutting machines are used to fabricate parts for vehicles, such as exhaust systems, componentes estruturais, and other precision parts. The ability to quickly and accurately cut through high-strength metals has led to better production timelines and higher-quality components.

◆ Aerospace and Aviation

Fiber lasers are used extensively in the aerospace and aviation industries for cutting lightweight metals and precision parts. The accuracy and repeatability of fiber lasers ensure that each component is made to exact specifications, meeting stringent quality and safety standards.

◆ Medical Industry

The medical device industry relies heavily on fiber laser cutting machines for producing surgical tools, implantes, and other medical components. These machines can cut complex shapes in materials like titanium, aço inoxidável, and other alloys, ensuring the safety and functionality of medical devices.

5. Factors to Consider When Choosing a Fiber Laser Metal Cutting Machine

When selecting a fiber laser metal cutting machine, it’s important to consider several factors to ensure you choose the right model for your needs.

◆ Material Type and Thickness

Fiber laser cutting machines are ideal for a variety of metals, but different machines are better suited for different thicknesses and materials. Por exemplo, a higher-powered laser is necessary for cutting thicker metals, while lower-powered lasers are sufficient for thinner materials. Be sure to select a machine that can handle the materials and thicknesses you typically work with.

◆ Laser Power

The power of the laser is another crucial factor to consider. Higher-power lasers are capable of cutting through thicker materials, while lower-power lasers are more efficient for cutting thinner materials. Choosing the right power level ensures optimal cutting speed and efficiency for your specific needs.

◆ Machine Size and Footprint

Consider the available space in your facility and the size of the machine when making your decision. Fiber laser cutting machines come in a range of sizes, so you can select one that fits your production capacity and floor space requirements.

◆ Software and Control Systems

The software that accompanies the laser cutting machine plays a significant role in ensuring that the cutting process is efficient and accurate. Advanced control systems can help with material nesting, job scheduling, and cutting path optimization, which can further improve productivity and material utilization.

6. Future of Fiber Laser Metal Cutting Technology

The future of fiber laser metal cutting machines is bright, with ongoing innovations in laser technology, automation, and software integration. As fiber lasers continue to evolve, manufacturers can expect even more improvements in cutting speeds, power efficiency, e precisão. These advancements will likely make fiber lasers even more accessible and versatile, enabling them to be used in new applications and industries.

As industries continue to push the boundaries of what is possible with fiber laser metal cutting machines, it is clear that this technology will remain a cornerstone of modern manufacturing, providing faster, mais preciso, and cost-effective solutions for cutting metal materials.

Notícias principais

-

4000Guia da máquina de corte a laser W | Fundamentos09 dezembro 2025

4000Guia da máquina de corte a laser W | Fundamentos09 dezembro 2025 -

Máquina de corte de metal a laser de fibra para venda05 dezembro 2025

Máquina de corte de metal a laser de fibra para venda05 dezembro 2025 -

4000 Watt Laser | Poder de corte industrial02 dezembro 2025

4000 Watt Laser | Poder de corte industrial02 dezembro 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa