Новости

Станок для лазерной резки портального типа с оптоволоконным кабелем: Передовые технологии точного производства

★ In the ever-evolving landscape of manufacturing, where precision, эффективность, and versatility reign supreme, тот **gantry type fiber laser cutting machine** stands as a beacon of technological advancement. Imagine a tool so precise that it can cut through metals as effortlessly as a hot knife through butter, yet versatile enough to handle a wide range of materials. This transformative technology is not just a tool but a revolution that is redefining industries, от автомобилестроения до аэрокосмической отрасли, and everything in between.

This comprehensive guide explores the intricacies of the gantry type fiber laser cutting machine—its working principles, преимущества, Приложения, and why it has become an indispensable asset for modern manufacturers. Whether you’re an industry professional, a small business owner, or a curious reader, this article is tailored to provide valuable insights into this groundbreaking technology.

1.What is a Gantry Type Fiber Laser Cutting Machine?

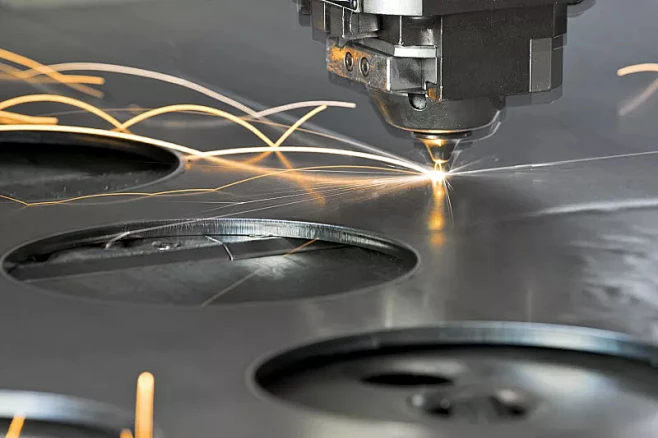

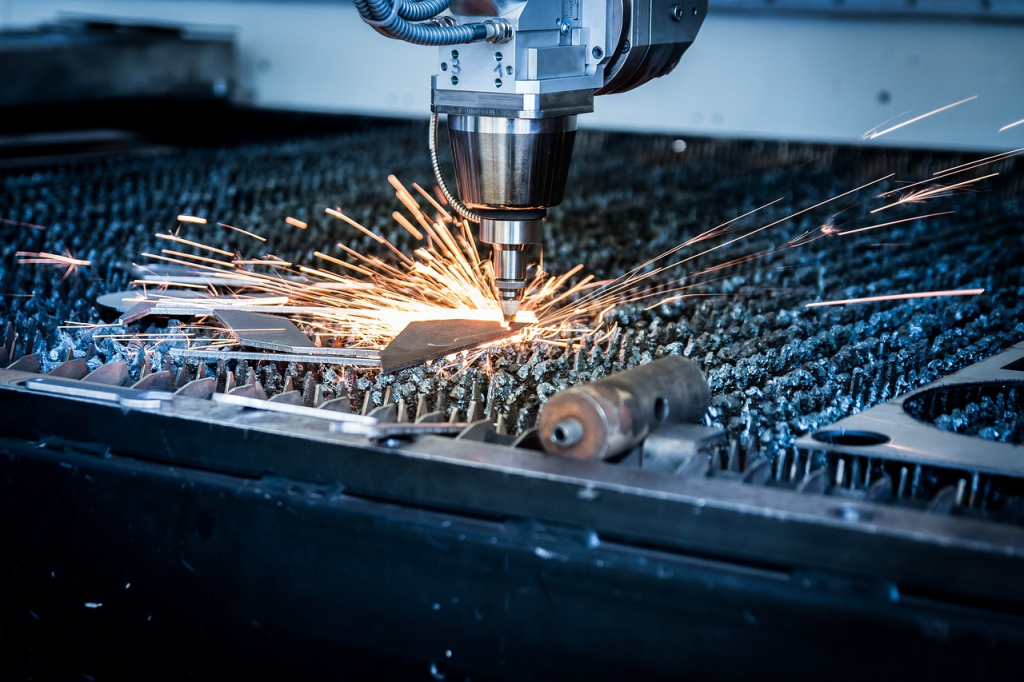

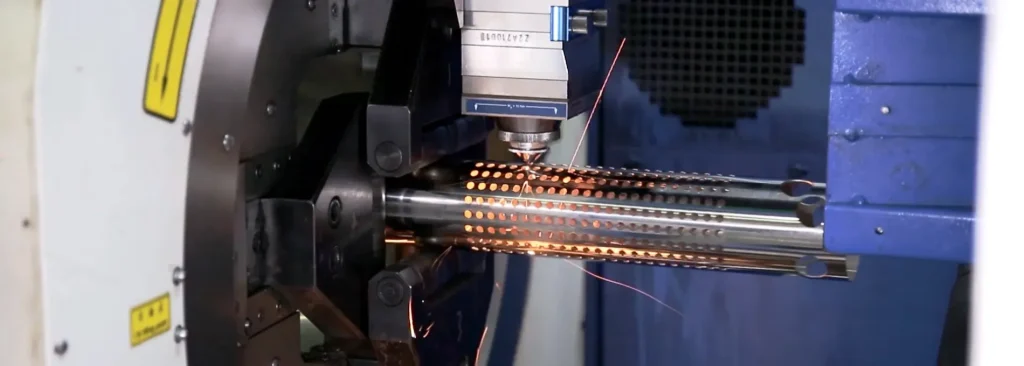

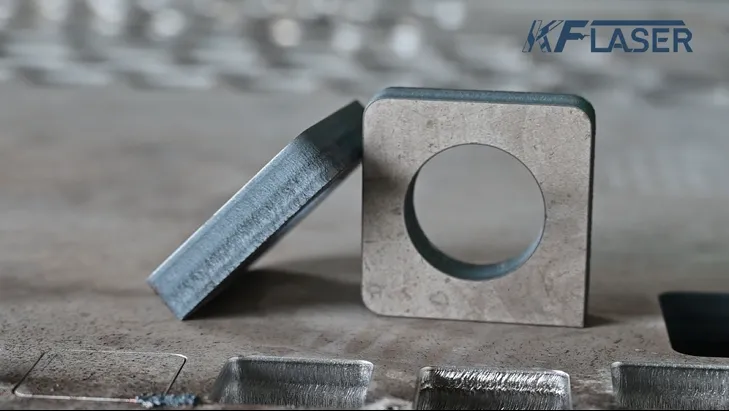

А gantry type fiber laser cutting machine is a high-precision tool designed to cut, гравировать, or mark a variety of materials, predominantly metals, using advanced fiber laser technology. The “gantry” in its name refers to its structural design, where the laser head moves along a gantry framework, allowing for stable and precise operation over large workpieces.

This machine’s core feature is its use of fiber lasers, which deliver a concentrated beam of energy capable of slicing through materials with unparalleled accuracy. Combined with the stability of the gantry structure, it ensures consistent and high-quality cuts, even for intricate designs.

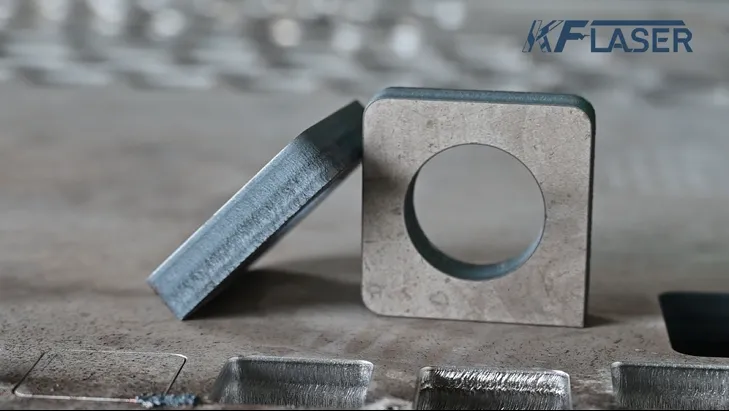

- Below is the cutting video of KF LASER’s HA series cutting machine. If you are interested, please click on our YOUTUBE homepage.

2.How Does a Gantry Type Fiber Laser Cutting Machine Work?

The operation of a gantry type fiber laser cutting machine can be broken down into several key stages:

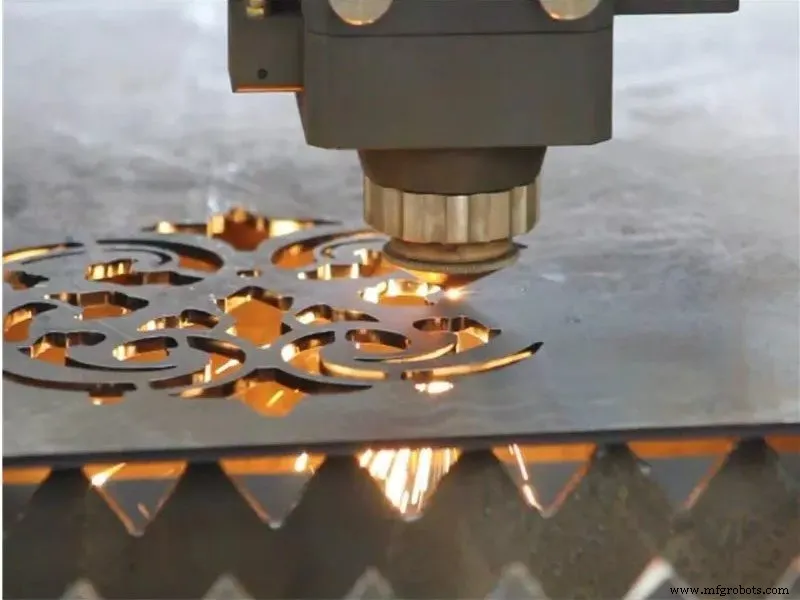

Laser cutting is a subtractive manufacturing process where a high-powered laser beam melts, испаряется, or burns through materials. Here’s a closer look at how it all works:

1. Лазерное поколение

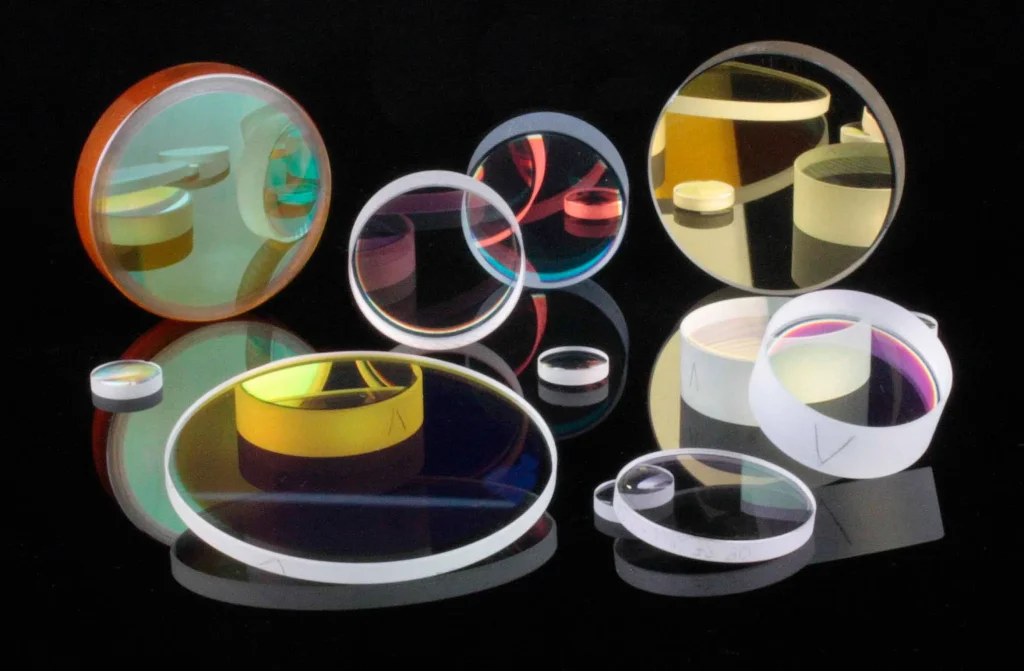

The machine utilizes a fiber laser source to produce a highly focused and intense laser beam. This beam is generated through an optical fiber infused with rare-earth elements like ytterbium, ensuring high energy efficiency and stability.

2. Луч фокусируется

The laser beam is directed through a series of lenses and mirrors to achieve precise focus. This concentrated energy is capable of reaching temperatures high enough to melt or vaporize the material at the cutting point.

3. Gantry Movement

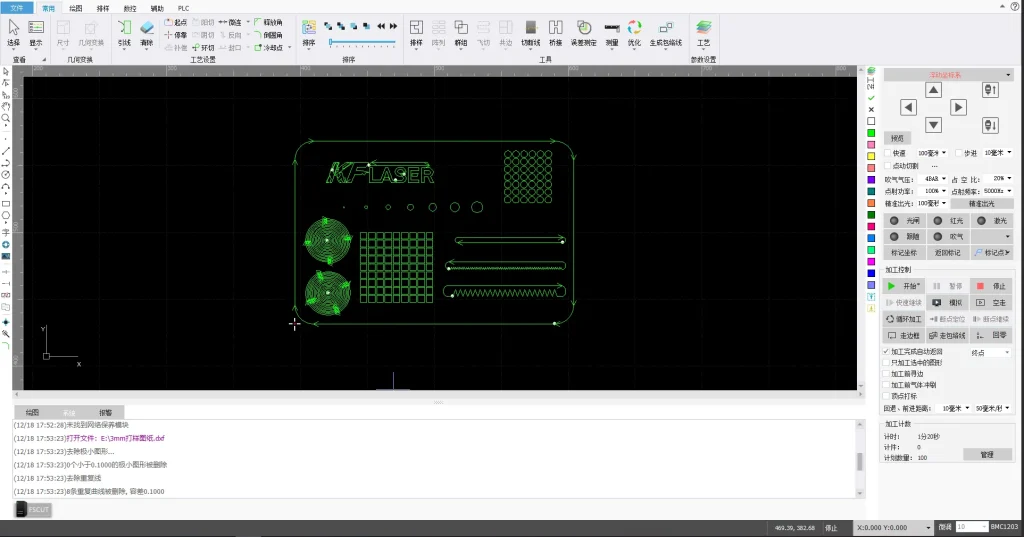

The gantry structure supports the laser head, enabling it to move along the X, Y, and sometimes Z axes. This movement is controlled by computer numerical control (ЧПУ) системы, ensuring accurate and repeatable cutting paths.

4. Материальная резка

As the laser beam makes contact with the material, it melts or vaporizes the material at the point of impact. Assist gases such as nitrogen or oxygen are used to remove molten material and improve cut quality.

5. Precision Control

The CNC system ensures that the laser follows the pre-programmed design with extreme precision. This allows for intricate cuts, плотные допуски, and minimal waste.

3.Advantages of Gantry Type Fiber Laser Cutting Machines

The gantry type fiber laser cutting machine offers numerous advantages over traditional cutting methods and even other laser technologies:

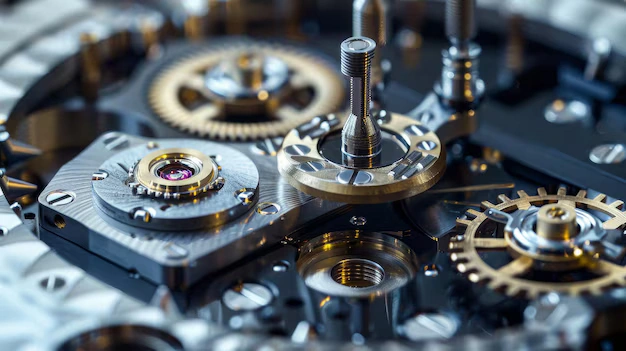

1. Высокая точность и точность

The combination of fiber laser technology and the stable gantry structure allows for extremely tight tolerances. This is crucial for industries requiring intricate designs and exact specifications.

2. Универсальность

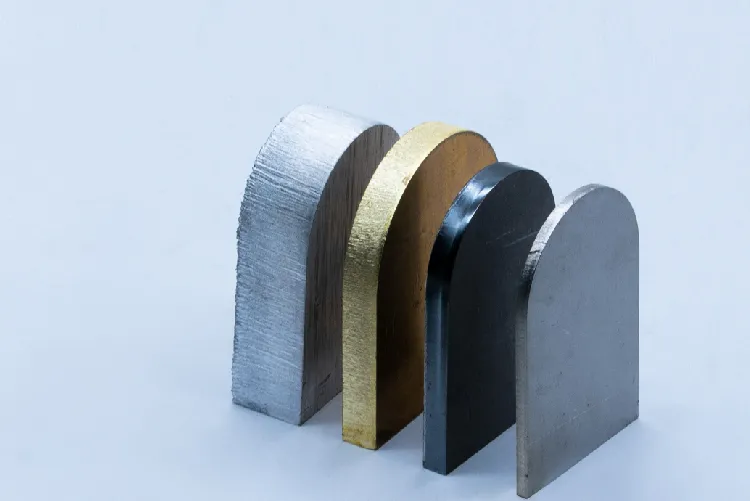

These machines can cut a wide range of materials, включая:

– **Metals**:Нержавеющая сталь, углеродистая сталь, алюминий, латунь, и титан.

– **Non-Metals**:Древесина, leather, акрил, и композиты.

This versatility makes them suitable for diverse applications, from automotive components to decorative items.

3. High-Speed Operation

Fiber lasers are known for their fast cutting speeds, especially on thin materials. This efficiency translates to higher productivity and reduced manufacturing times.

4. Минимальное обслуживание

Fiber lasers have fewer moving parts compared to other laser types, resulting in lower maintenance costs and longer service life. The robust gantry structure further enhances durability.

5. Экономическая эффективность

Хотя первоначальные инвестиции могут быть высокими, the operational costs are significantly lower due to energy efficiency, minimal consumable usage, and reduced maintenance requirements.

6. Environmental Friendliness

The non-contact cutting method minimizes waste and eliminates the need for chemical treatments. Кроме того, the use of assist gases ensures a cleaner cutting process with minimal emissions.

4.Applications of Gantry Type Fiber Laser Cutting Machines

1. Автоматизированная индустрия

В автомобильном секторе, these machines are used to cut complex parts like body panels, кронштейны, and exhaust systems with high precision.

2. Aerospace and Shipbuilding

The ability to handle large workpieces and thick materials makes them indispensable for fabricating components used in airplanes, ships, and submarines.

3. Изготовление Металла

From cutting steel sheets to producing custom metal parts, these machines are a staple in metal fabrication workshops.

4. Производство электроники

The precision of fiber lasers is ideal for creating intricate parts for electronic devices, including circuit boards and enclosures.

5. Строительство и Архитектура

The versatility of these machines allows architects and builders to create custom designs, декоративные панели, и структурные компоненты.

6. Медицинское оборудование

Gantry laser cutting machines are used to manufacture surgical instruments, имплантаты, and other medical devices requiring high precision and cleanliness.

5.Key Features of Gantry Type Fiber Laser Cutting Machines

1. Gantry Structure:

Ensures stability and precision, supporting large workpieces.

2.Fiber Laser Technology:

Provides high energy efficiency and superior beam quality.

3. Automatic Height Adjustment:

Поддерживает оптимальное расстояние между лазерной головкой и материалом..

4. Управление ЧПУ:

Enables precise and repeatable cutting paths.

5. Помогать газовой системе:

Improves cut quality and removes debris.

6.Choosing the Right Gantry Type Fiber Laser Cutting Machine

When selecting a gantry type fiber laser cutting machine, учитывать следующие факторы:

1. Совместимость материалов:

Ensure the machine can handle the materials you work with.

2. Cutting Area:

Choose a machine with a workspace that meets your production needs.

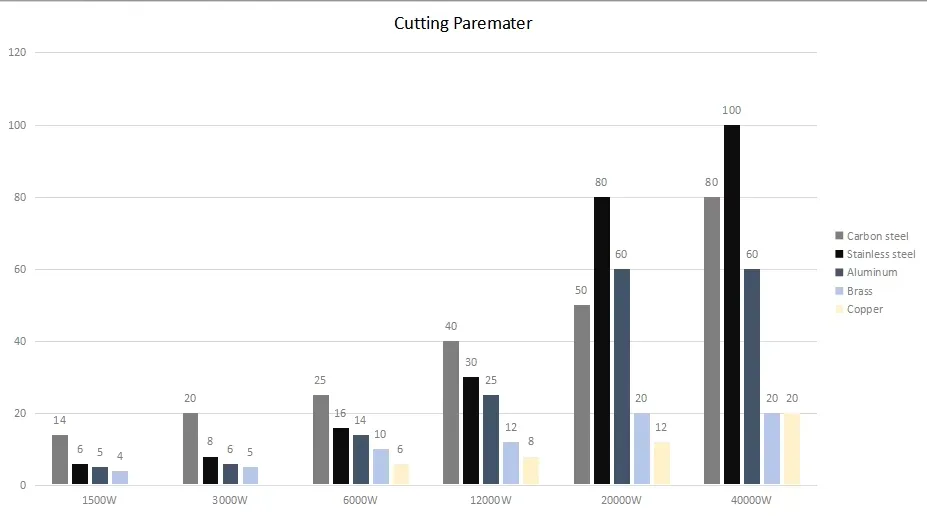

3. Мощность лазера:

Select the appropriate power level for the materials and thicknesses you plan to cut.

4. Возможности автоматизации:

Look for features like automatic height adjustment and advanced CNC controls.

5. Требования к техническому обслуживанию:

Opt for machines with low maintenance demands to minimize downtime.

7.The Role of KF LASER in Gantry Fiber Laser Cutting

КФ ЛАЗЕР has emerged as a leader in the field of gantry type fiber laser cutting machines, offering cutting-edge solutions tailored to meet the diverse needs of modern manufacturers. Their machines are known for their reliability, точность, и эффективность, making them a trusted choice for industries worldwide.

8.Tips for Maximizing Efficiency with Gantry Type Fiber Laser Cutting Machines

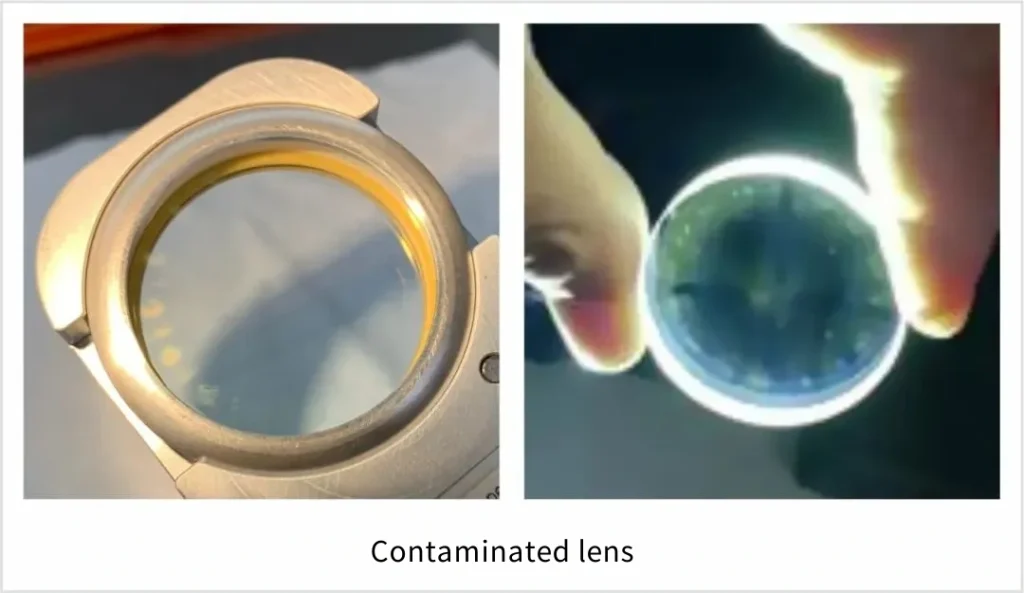

1. Регулярное техническое обслуживание:

Clean lenses, replace worn-out parts, and lubricate moving components to ensure optimal performance.

2. Оптимизация параметров резки:

Adjust laser power, скорость, and assist gas settings based on the material being cut.

3. Инвестируйте в обучение:

Ensure operators are well-trained to maximize the machine’s capabilities.

4. Use Quality Materials:

High-quality materials produce better results and reduce wear on the machine.

5. Leverage CNC Features:

Utilize nesting software and advanced programming to minimize material waste and improve productivity.

9.Future Trends in Gantry Type Fiber Laser Cutting Machines

Поскольку технологии продолжают развиваться, we can expect several innovations in gantry type fiber laser cutting machines:

1. Integration with AI:

Artificial intelligence will enable real-time optimization of cutting paths and parameters.

2. Higher Laser Powers:

Advances in laser technology will allow for faster cutting of thicker materials.

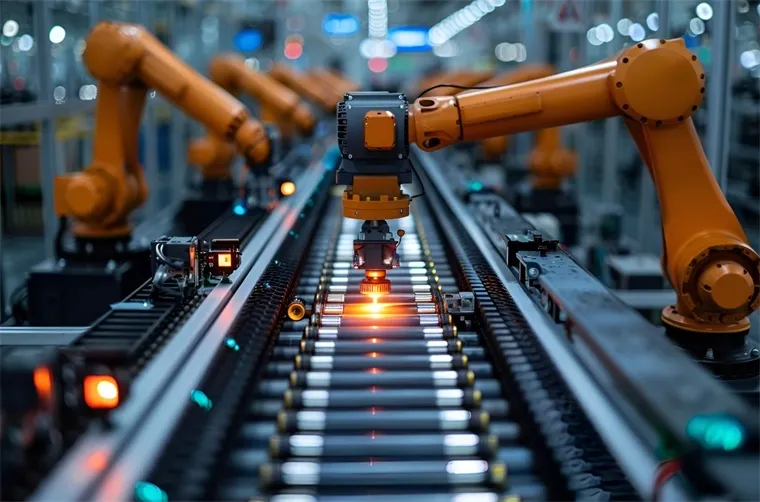

3. Улучшенная автоматизация:

Fully automated systems will reduce human intervention and increase efficiency.

4. Sustainability Features:

Machines will incorporate eco-friendly technologies to minimize environmental impact.

10.Transforming Industries with Precision

The gantry type fiber laser cutting machine is not just a tool; it is a game-changer. By combining unparalleled precision, универсальность, и эффективность, it has become a cornerstone of modern manufacturing. From automotive parts to medical devices, its applications are as diverse as they are impactful. Поскольку технологии продолжают развиваться, the potential of this remarkable machine will only grow, paving the way for new possibilities in design and production.

For businesses looking to stay ahead in a competitive market, investing in a gantry type fiber laser cutting machine from KF LASER is a step toward unmatched quality and productivity.

Главные новости

-

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025 -

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025 -

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025 -

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025 -

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина