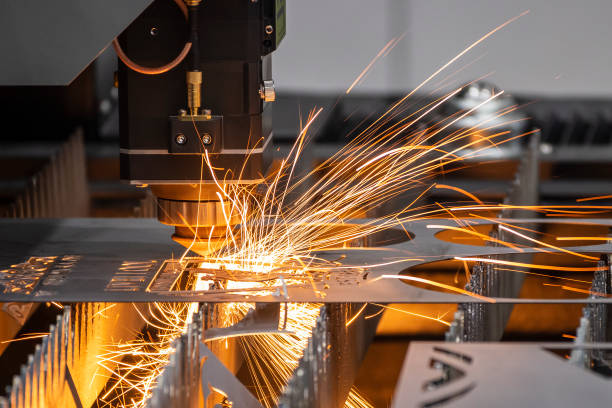

Industrial laser cutting machines have revolutionized the manufacturing landscape, offering unprecedented precision, velocidade, and versatility across a wide range of industries. Do automotivo à eletrônica, and aerospace to medical, these machines are pivotal in creating intricate parts with remarkable efficiency. This article delves into the core aspects of industrial laser cutting machines, exploring their key advantages, applications across various sectors, and how they’ve transformed modern manufacturing.

Industrial laser cutting machines use concentrated beams of light to cut, forma, and engrave various materials. These machines leverage advanced technology to direct a high-powered laser onto the material’s surface, cutting through it with remarkable precision. The lasers employed in industrial settings are typically lasers de fibra, Lasers de CO2, or crystal lasers, each suited to specific materials and applications.

O processo de corte pode ser térmico, derretendo o material à medida que o feixe de laser se move através, ou vaporizando o material de uma maneira que deixe um ambiente limpo, borda acabada. Independentemente do processo, a tecnologia de corte a laser é altamente eficiente, minimizando o desperdício de material e reduzindo significativamente o tempo necessário para a produção.

2.The Key Advantages of Industrial Laser Cutting Machines

Precisão e exatidão

One of the most significant advantages of laser cutting machines is their precision. Industrial laser cutters can achieve cuts with tolerances of a few micrometers, garantindo resultados de alta qualidade, even for complex designs. This precision is particularly valuable in industries where accuracy is paramount, como fabricação aeroespacial e de dispositivos médicos.

Velocidade e eficiência

Laser cutting machines operate at remarkable speeds compared to traditional methods. Whether cutting metal, plástico, madeira, or composite materials, laser technology significantly reduces production time. For industries like automotive or electronics, where fast turnaround is critical, the speed of laser cutters directly translates into enhanced productivity.

Versatility Across Materials

Industrial laser cutting machines are capable of cutting a wide variety of materials, including metals like steel, alumínio, e titânio, as well as non-metals like plastics, madeira, e até cerâmica. This versatility allows manufacturers to use a single machine for multiple applications, streamlining production and lowering operational costs.

Reduced Waste and Material Use

Ao contrário das ferramentas de corte tradicionais, which often result in significant waste due to physical tool wear and inefficient material use, laser cutters minimize waste. The narrow laser beam creates precise cuts with minimal material loss. For industries focused on sustainability, this reduction in waste is a crucial benefit.

Automação e Integração

Modern industrial laser cutting machines can be easily integrated into automated production lines. Using CAD (computer-aided design) software, operators can design complex parts and feed those designs directly into the laser cutter, ensuring consistency and accuracy across all parts produced. Automation reduces human error, increases speed, and improves overall production quality.

Minimal Maintenance and Long Lifespan

Laser cutting machines are known for their durability and minimal maintenance needs. The core component of a laser cutter, the laser source, can function for extended periods without degradation. Adicionalmente, since there is no physical contact between the cutting tool and the material, wear and tear are minimized, ensuring a longer lifespan for the equipment.

Indústria automobilística

The automotive sector relies heavily on industrial laser cutting machines for the production of body panels, sistemas de escape, and intricate parts such as airbags and braking systems. These machines are favored for their ability to cut complex shapes with high precision, which is critical in ensuring the safety and performance of automotive components.

Laser cutting machines allow for faster prototyping and production, which is especially important as automotive designs evolve to incorporate more complex geometries and lightweight materials. Adicionalmente, laser cutters are used for welding and marking automotive parts, ensuring traceability and quality control throughout the production process.

Aeroespacial e aviação

Na indústria aeroespacial, precision and material integrity are critical, making laser cutting technology an ideal solution. Laser cutters are employed to fabricate parts from high-strength materials like titanium and aluminum alloys. These materials are often used in aircraft frames, Componentes do motor, and landing gear systems.

Laser technology also allows for the production of lightweight components, which is essential in the aerospace sector to enhance fuel efficiency. With the growing demand for space exploration and commercial aviation, laser cutting machines have become integral to meeting stringent industry standards.

Fabricação de equipamentos médicos

The medical device industry is another key area where industrial laser cutting machines excel. The high precision of laser cutting is vital for manufacturing medical implants, surgical instruments, e equipamento de diagnóstico. These devices often require micro-cuts that only laser technology can achieve with the necessary accuracy.

Laser cutting is also used in the production of stents, catheters, and prosthetics. The ability to cut both metals and plastics with equal precision makes laser technology indispensable in medical equipment manufacturing, ensuring that all components meet the strict safety and performance standards required in healthcare.

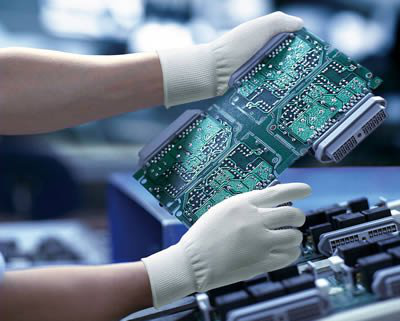

Indústria de eletrônicos

In the electronics sector, laser cutting machines are used to cut delicate components like circuit boards, conectores, and microchips. The precision required in electronics manufacturing is immense, and laser cutters provide the fine detail needed for intricate designs.

Laser cutting is also applied in the production of displays, sensors, and heat sinks, ensuring that the electronic devices we use daily, from smartphones to computers, function flawlessly. Além disso, laser technology enables faster production cycles, keeping pace with the rapid innovation and demand in the electronics market.

Construção e Arquitetura

The construction industry uses industrial laser cutting machines to fabricate structural elements for buildings, bridges, and infrastructure projects. Laser cutters handle large-scale metal components with ease, ensuring precision in the production of steel beams, connection plates, and other critical construction materials.

Architectural firms also use laser technology to create intricate designs in metal, madeira, e vidro, enabling the realization of complex building facades and interior features that would be difficult or impossible to achieve using traditional methods.

Furniture and Interior Design

In the furniture industry, laser cutting machines are used to create modern designs with precision. Laser technology allows manufacturers to cut intricate patterns in materials such as wood, metal, and acrylic, enabling the production of unique, customized furniture pieces.

The ability to quickly switch between different materials and design patterns makes laser cutting machines an invaluable tool in interior design. Whether it’s creating decorative panels, lighting fixtures, or bespoke furniture items, the precision and versatility of laser cutting are unmatched.

Fitness Equipment Manufacturing

As health and fitness trends grow, so does the demand for high-quality fitness equipment. Laser cutting technology is used to manufacture gym equipment like treadmills, weight machines, and exercise bikes. The ability to cut metal tubing and sheets precisely ensures the durability and reliability of these products.

Laser cutting also allows fitness equipment manufacturers to innovate, creating ergonomic designs that improve user experience. Além disso, laser marking is used to add brand logos and product information, enhancing the equipment’s professional appearance.

Máquinas de corte a laser de CO2

CO2 laser cutting machines are widely used in industries for cutting non-metal materials such as wood, acrílico, vidro, and fabrics. These machines use carbon dioxide gas as the laser medium, producing high-energy beams capable of cutting through thick, non-metallic materials.

CO2 lasers are commonly used in industries where precise engraving and cutting are required, such as in sign-making, textile production, and interior design.

Máquinas de corte a laser de fibra

Fiber lasers are among the most efficient and versatile types of industrial laser cutting machines. They are primarily used for cutting metals, incluindo aço, alumínio, e latão. Fiber lasers are known for their high-speed cutting and energy efficiency, making them ideal for high-volume industrial applications.

These lasers use optical fibers to amplify the laser beam, producing a highly focused and precise cut. Fiber lasers are increasingly popular in industries like aerospace, Automotivo, and electronics due to their versatility and minimal maintenance requirements.

Máquinas de corte a laser de cristal

Lasers de cristal, como Nd:YAG e Nd:Lasers YVO, are used for cutting metals and certain plastics. These lasers are known for their high precision and ability to handle thicker materials. No entanto, they tend to be more expensive and have a shorter lifespan than fiber or CO2 lasers, making them less common in high-volume production environments.

Crystal laser cutting machines are typically used in industries requiring extremely precise cutting, such as in medical device manufacturing and certain electronics applications.

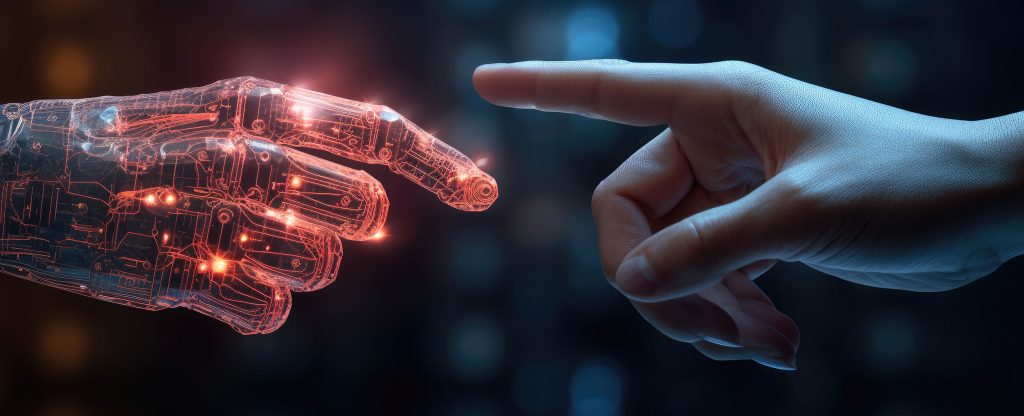

The future of industrial laser cutting machines is bright, with ongoing advancements in automation, IA, and material science. Machine learning algorithms are being integrated into laser cutting systems, allowing for real-time optimization of cutting paths and material usage. This will further increase efficiency and reduce waste in manufacturing processes.

Adicionalmente, new materials and laser sources are being developed that will expand the capabilities of laser cutting machines, allowing them to cut even more diverse materials with greater precision and speed.

Além disso, as industries continue to prioritize sustainability, laser cutting machines will play a key role in reducing energy consumption and material waste, helping manufacturers meet environmental regulations while maintaining high productivity.

Industrial laser cutting machines are at the forefront of modern manufacturing, providing unparalleled precision, velocidade, e versatilidade. From the automotive and aerospace industries to medical equipment manufacturing and electronics, these machines are essential in creating the complex components that power today’s technology-driven world.

As advancements in laser technology continue, laser cutting machines will only become more integral to industrial processes, offering even greater efficiency, precisão, and sustainability across a diverse range of applications.