Notícias

Um guia abrangente para máquinas de corte a laser de folha de ferro

No cenário em constante evolução da manufatura, a tecnologia de corte a laser tornou-se indispensável, oferecendo precisão e eficiência. Uma das aplicações de destaque desta tecnologia está em máquinas de corte a laser para chapas de ferro, projetado para cortar chapas de ferro com alta precisão. Estas máquinas estão ganhando popularidade em todos os setores devido à sua capacidade de produzir produtos limpos., cortes precisos em uma fração do tempo que os métodos tradicionais levam.

Neste artigo, vamos nos aprofundar no que torna as máquinas de corte a laser para chapas de ferro únicas, os benefícios de usá-los, como eles funcionam, e os diferentes fatores a serem considerados ao selecionar a máquina certa para suas necessidades. No final, você terá uma compreensão abrangente do potencial que essas máquinas têm para transformar seus processos de fabricação.

1. O que é uma máquina de corte a laser para chapas de ferro?

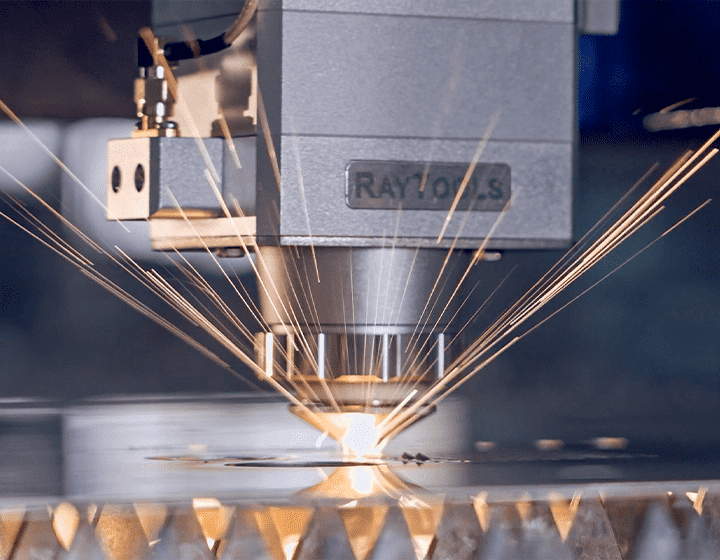

Uma máquina de corte a laser para chapas de ferro é um equipamento altamente especializado, projetado para cortar chapas de ferro e materiais metálicos semelhantes com precisão incomparável.. Usando um feixe de laser focado, essas máquinas derretem, queimar, ou vaporizar o material, permitindo que designs complexos e intrincados sejam cortados sem contato físico.

O que diferencia o corte a laser de chapas de ferro é a capacidade do laser de criar cortes extremamente finos e detalhados que mantêm a integridade do material.. Seja para construção, Automotivo, ou mesmo para fins artísticos, a tecnologia por trás do corte a laser de chapas de ferro foi projetada para reduzir o desperdício, otimizar o tempo de produção, e aumentar a eficiência geral.

- Como funciona

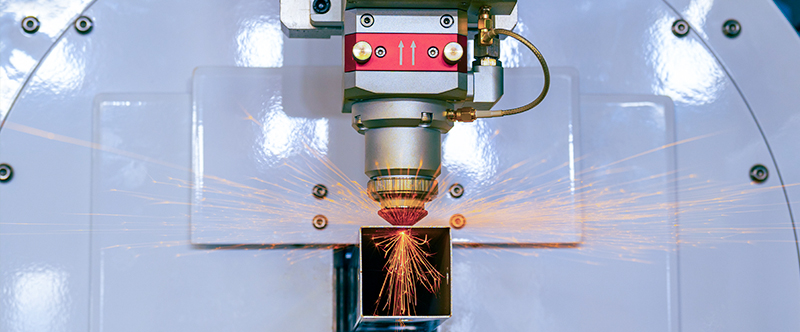

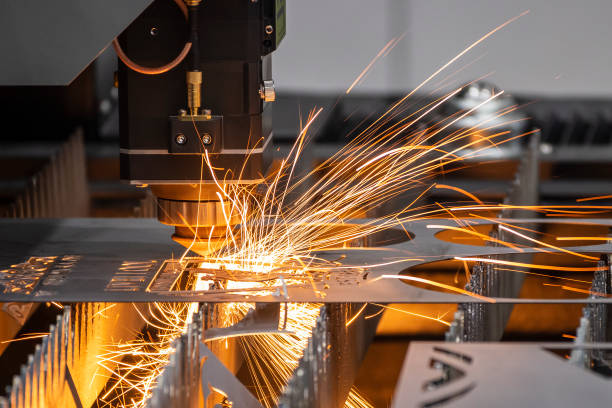

No centro da máquina de corte a laser para chapas de ferro está a fonte do laser, que gera um feixe de luz de alta potência. Este feixe é focado através da óptica e direcionado por controle numérico computadorizado (CNC) tecnologia, garantindo precisão no processo de corte.

O feixe de laser aquece a chapa de ferro a uma temperatura que derrete ou vaporiza o material, e um gás de alta pressão, como nitrogênio ou oxigênio, é usado para soprar o metal fundido do corte. Isto resulta em uma suave, acabamento de alta qualidade, reduzindo a necessidade de processamento adicional.

Existem diversas técnicas de corte que podem ser empregadas dependendo da espessura e das características específicas da chapa de ferro.. Estes incluem:

- Corte por fusão: O laser derrete o material, e um jato de gás remove o metal fundido, criando uma borda limpa.

- Corte por vaporização: Isso envolve transformar o material diretamente em vapor sem derretê-lo., normalmente usado para folhas finas ou aplicações delicadas.

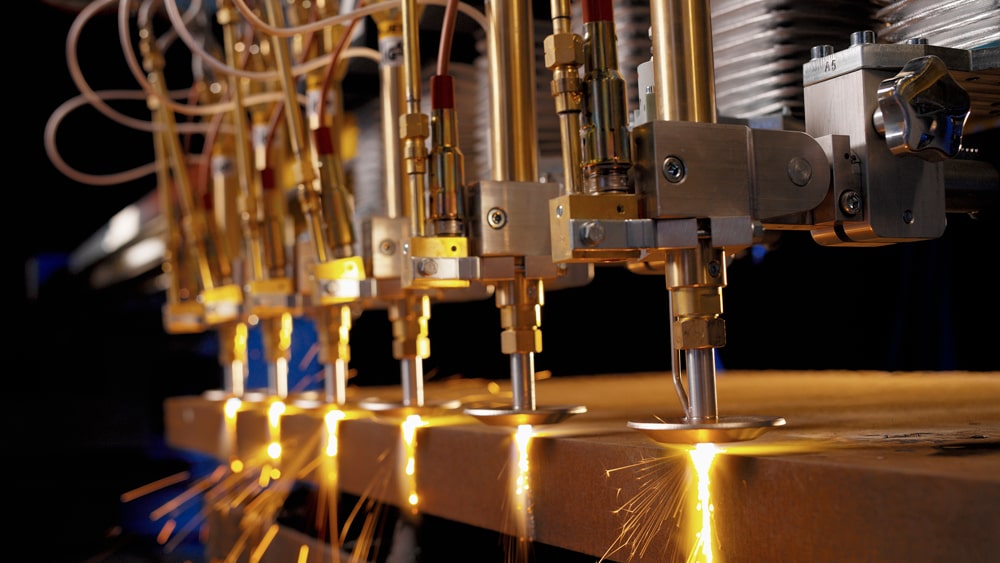

- Corte reativo: Também conhecido como corte por chama, esta técnica usa oxigênio para criar uma reação exotérmica, adicionando calor extra para auxiliar no corte de chapas de ferro mais grossas.

2. Principais benefícios do uso de máquinas de corte a laser para chapas de ferro

- Alta Precisão e Exatidão

Uma das maiores vantagens de uma máquina de corte a laser para chapas de ferro é a precisão que ela oferece. Estas máquinas são capazes de cortar chapas de ferro com tolerâncias extremamente finas, o que é crucial em indústrias que exigem detalhes intrincados e erros mínimos. Com as configurações certas, o corte a laser pode atingir precisão tão alta quanto 0.001 milímetros.

Esta precisão torna o corte a laser a solução ideal para aplicações que exigem padrões altamente detalhados, como metalurgia arquitetônica, componentes industriais, ou projetos de fabricação personalizados.

- Velocidade e eficiência

Outro benefício notável é a velocidade com que as máquinas de corte a laser de chapas de ferro operam. Métodos tradicionais, como corte mecânico, tendem a ser mais lentos e propensos a erros devido ao desgaste. Corte a laser, por outro lado, permite que os fabricantes aumentem o rendimento da produção sem sacrificar a qualidade.

Em indústrias como automotiva e aeroespacial, onde são necessários grandes volumes de peças metálicas, a alta velocidade das máquinas de corte a laser leva a reduções significativas no tempo de produção, em última análise, reduzindo os custos operacionais.

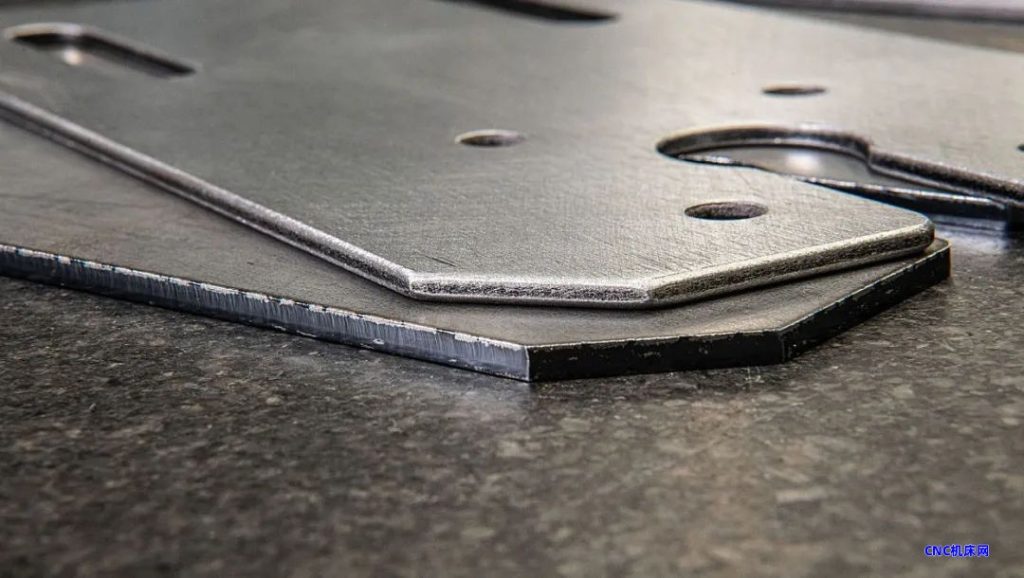

- Limpar, Cortes de alta qualidade

A precisão do corte a laser garante que as bordas da chapa de ferro cortada sejam lisas e limpas. Isto reduz ou elimina a necessidade de processos secundários como lixamento ou polimento, economizando tempo e dinheiro.

Porque o feixe de laser está tão focado, minimiza a zona afetada pelo calor (HAZ) ao redor do corte, reduzindo o risco de deformação ou empenamento do material. Isto torna o corte a laser especialmente eficaz para cortar chapas de ferro em aplicações onde a resistência e integridade do material são críticas.

- Versatilidade entre aplicativos

Embora a função principal dessas máquinas seja o corte de chapas de ferro, sua versatilidade se estende a uma ampla gama de outros materiais, incluindo aço inoxidável, alumínio, e até mesmo não-metais como plásticos e madeira. Isso os torna adequados para vários setores, desde manufatura pesada e construção até áreas mais delicadas, como eletrônica e fabricação de joias.

- Econômico ao longo do tempo

Embora o investimento inicial em uma máquina de corte a laser para chapas de ferro possa ser alto, A economia de longo prazo é significativa. Redução do desperdício de materiais, tempos de produção mais rápidos, e requisitos mínimos de manutenção se traduzem em custos operacionais mais baixos ao longo do tempo. Adicionalmente, a versatilidade dessas máquinas elimina a necessidade de vários tipos de equipamentos, consolidando funções em uma máquina.

3. Tipos de máquinas de corte a laser para chapas de ferro

Ao selecionar uma máquina de corte a laser para chapas de ferro, é essencial compreender os diferentes tipos de lasers disponíveis e como eles são adequados para tarefas específicas. Os três tipos mais comumente usados de máquinas de corte a laser são CO2, fibra, e lasers de cristal, cada um com seus pontos fortes e aplicações.

- Máquinas de corte a laser de CO2

Os lasers de CO2 são uma das formas mais antigas e amplamente utilizadas de tecnologia de corte a laser. Eles são particularmente eficazes para cortar materiais não metálicos, mas também são capazes de cortar metais como ferro quando combinados com a mistura de gás correta.

Os lasers de CO2 são geralmente mais acessíveis do que outros tipos e são adequados para indústrias que trabalham com uma combinação de metais e não metais.. No entanto, para chapas de ferro mais espessas, Os lasers de CO2 podem não ser tão eficientes ou econômicos quanto as tecnologias mais recentes, como os lasers de fibra.

Os lasers de fibra são a tecnologia mais avançada e eficiente para cortar metais como ferro. Esses lasers usam cabos de fibra óptica para amplificar a luz, tornando-os incrivelmente precisos e rápidos. O menor comprimento de onda dos lasers de fibra permite cortar metais reflexivos como o ferro sem o risco de danificar a máquina, o que é uma limitação dos lasers de CO2.

Lasers de fibra também têm custos operacionais mais baixos, expectativa de vida mais longa, e são mais eficientes em termos energéticos. Para indústrias que exigem corte em alta velocidade de chapas grossas de ferro, máquinas a laser de fibra são a melhor opção.

- Máquinas de corte a laser de cristal

Lasers de cristal, como Nd:YAG e Nd:Lasers YVO, são de alta potência e capazes de cortar metais grossos, incluindo ferro. Eles são normalmente usados em indústrias que exigem cortes muito precisos e detalhes finos, como fabricação aeroespacial e de dispositivos médicos. No entanto, essas máquinas são mais caras de manter e têm uma vida operacional mais curta do que os lasers de fibra ou CO2.

4. Fatores a serem considerados ao escolher uma máquina de corte a laser para chapas de ferro

A escolha da máquina de corte a laser para chapas de ferro certa depende de vários fatores, cada um dos quais afetará a eficiência, custo, e qualidade do seu processo de produção. Abaixo estão as considerações críticas que você deve ter em mente ao tomar sua decisão.

- Espessura e tipo de material

A espessura das chapas de ferro que você planeja cortar é um dos fatores mais importantes a considerar. Como regra geral, lasers de fibra são mais adequados para cortar materiais mais espessos, enquanto os lasers de CO2 são ideais para materiais mais finos. Adicionalmente, considere se você precisa de uma máquina que possa lidar com uma variedade de materiais, pois algumas máquinas são mais versáteis que outras.

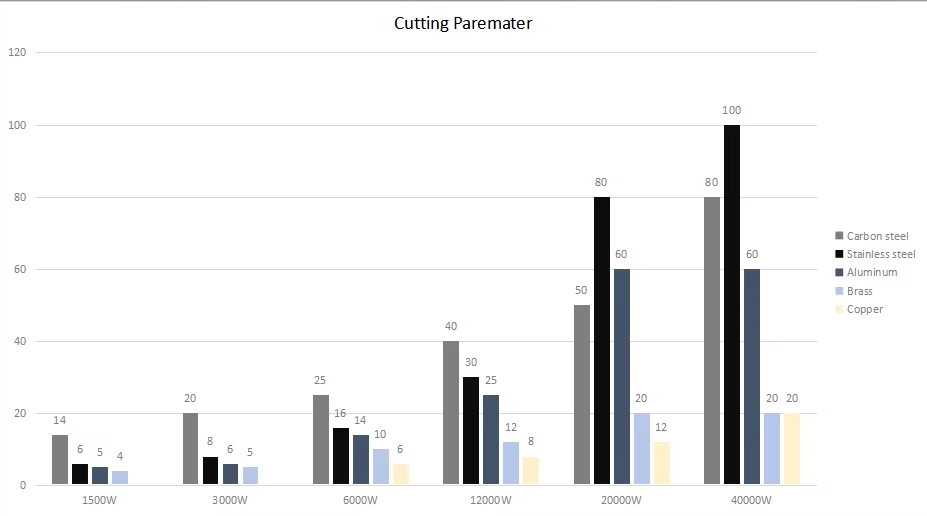

- Potência da máquina

A potência nominal da máquina a laser está diretamente correlacionada com sua velocidade de corte e capacidade de lidar com diferentes materiais. Máquinas de maior potência podem cortar chapas mais espessas com mais eficiência, mas podem acarretar custos operacionais mais elevados. É essencial combinar a potência da máquina com os seus requisitos específicos de corte para garantir um desempenho ideal.

- Tamanho da área de trabalho

O tamanho da área de trabalho é outro fator crucial, especialmente se você estiver lidando com grandes chapas de ferro ou precisar cortar várias chapas simultaneamente. Certifique-se de que a máquina tenha espaço suficiente para acomodar seus materiais maiores, bem como espaço para quaisquer operações adicionais que você possa precisar, como gravação ou marcação.

- Facilidade de uso e automação

Máquinas avançadas de corte a laser para chapas de ferro vêm equipadas com sistemas CNC, tornando-os altamente automatizados. No entanto, a facilidade de uso ainda é uma consideração importante, especialmente se você quiser minimizar a necessidade de treinamento especializado. Máquinas mais fáceis de operar podem reduzir o tempo de inatividade e melhorar a produtividade, especialmente em ambientes de ritmo acelerado.

- Manutenção e durabilidade

Máquinas de corte a laser, particularmente lasers de fibra e cristal, têm vida útil mais longa e exigem menos manutenção do que os lasers de CO2. No entanto, é importante escolher uma máquina que ofereça fácil acesso aos componentes, bem como suporte confiável ao cliente e peças de reposição prontamente disponíveis.

5.Melhores práticas para corte a laser de chapas de ferro

Para aproveitar ao máximo sua máquina de corte a laser para chapas de ferro, é importante seguir as melhores práticas que garantam eficiência e qualidade. Aqui estão algumas dicas para otimizar seu processo de corte:

- Otimize as configurações do laser para espessura do material

Cada material requer um conjunto específico de parâmetros de laser para um corte ideal. Para chapas de ferro, certifique-se de ajustar a potência e a velocidade do laser para corresponder à espessura e ao grau do material. Isso evitará o superaquecimento e reduzirá o risco de danos ao material e à máquina.

- Mantenha a óptica limpa

Óptica suja ou desalinhada pode afetar a qualidade do corte e reduzir a eficiência geral da máquina. Limpe regularmente as ópticas e certifique-se de que estão corretamente alinhadas para manter o desempenho de corte ideal.

- Use o gás auxiliar correto

Gases auxiliares como oxigênio, azoto, e o argônio desempenham um papel vital no processo de corte. Para chapas de ferro, o oxigênio é normalmente usado para aumentar o poder de corte do laser, enquanto o nitrogênio pode ser usado para criar um ambiente limpo, borda livre de oxidação. Escolher o gás certo para sua aplicação específica melhorará a qualidade do corte e prolongará a vida útil da sua máquina.

- Manutenção regular da máquina

Para garantir um desempenho consistente, a manutenção regular da sua máquina de corte a laser é essencial. Isso inclui

verificando desgaste em componentes importantes, como lentes, espelhos, e a própria fonte de laser. A manutenção preventiva não só prolonga a vida útil da sua máquina, mas também ajuda a evitar tempos de inatividade dispendiosos.

6. Aplicações de máquinas de corte a laser para chapas de ferro

A versatilidade das máquinas de corte a laser para chapas de ferro as torna adequadas para uma ampla gama de indústrias. Aqui estão algumas das aplicações mais comuns:

- Indústria automobilística

No setor automotivo, o corte a laser é usado para criar peças precisas para veículos, incluindo painéis de carroceria, Componentes do motor, e sistemas de exaustão. A precisão e a velocidade do corte a laser garantem que as peças sejam produzidas de acordo com as especificações exatas, melhorar a qualidade geral e a segurança dos veículos.

- Construção e Arquitetura

Chapas de ferro cortadas a laser são comumente usadas na construção para criar trabalhos em metal complexos, como fachadas de edifícios, grades, e suportes estruturais. A capacidade de criar projetos detalhados com rapidez e precisão tornou o corte a laser um elemento básico no projeto arquitetônico moderno..

- Fabricação industrial

Em ambientes industriais, máquinas de corte a laser para chapas de ferro são usadas para criar tudo, desde componentes de máquinas até projetos de fabricação em grande escala. A precisão e a velocidade do corte a laser tornam-no ideal para produção em massa, bem como para criar peças personalizadas para máquinas especializadas.

- Usos Artísticos e Decorativos

Chapas de ferro cortadas a laser chegaram ao mundo da arte e do design, com artistas e fabricantes que usam a tecnologia para criar esculturas complexas, painéis de parede, e itens decorativos. A capacidade de produzir padrões complexos com o mínimo de desperdício de material torna o corte a laser uma opção atraente para projetos criativos.

7. O futuro das máquinas de corte a laser para chapas de ferro

À medida que a tecnologia continua a avançar, máquinas de corte a laser para chapas de ferro estão se tornando mais eficientes, versátil, e acessível. Inovações em automação, Otimização baseada em IA, e o consumo de energia mais ecológico provavelmente moldará o futuro do corte a laser, tornando-o uma parte ainda mais integrante da fabricação moderna.

Em particular, a integração da IA com máquinas de corte a laser pode permitir ajustes em tempo real, reduzindo desperdícios e otimizando ainda mais o processo de produção. À medida que as indústrias continuam a priorizar a sustentabilidade e a eficiência, a tecnologia de corte a laser está preparada para desempenhar um papel central na evolução das práticas de fabricação.

Estas máquinas continuam a oferecer uma precisão incomparável, velocidade, e eficiência, atendendo às necessidades de vários setores e ampliando os limites do que é possível na fabricação.

Notícias principais

-

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa