Новости

Лазерные станки для резки металла: Революция в точности в производстве

★ Preface

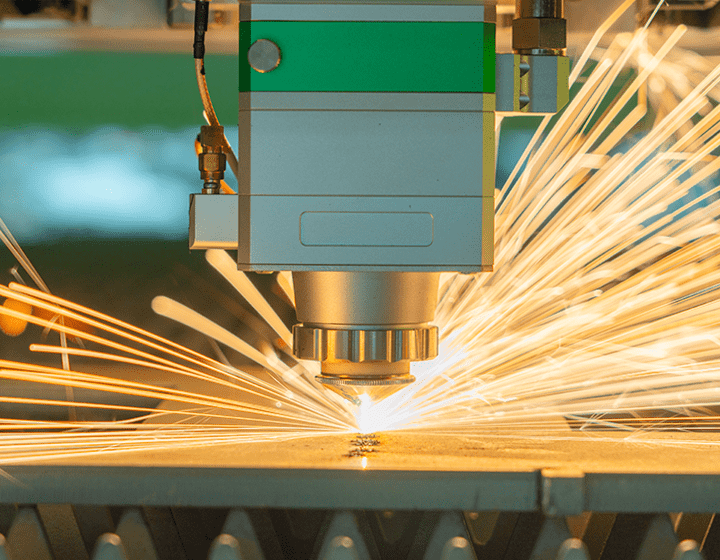

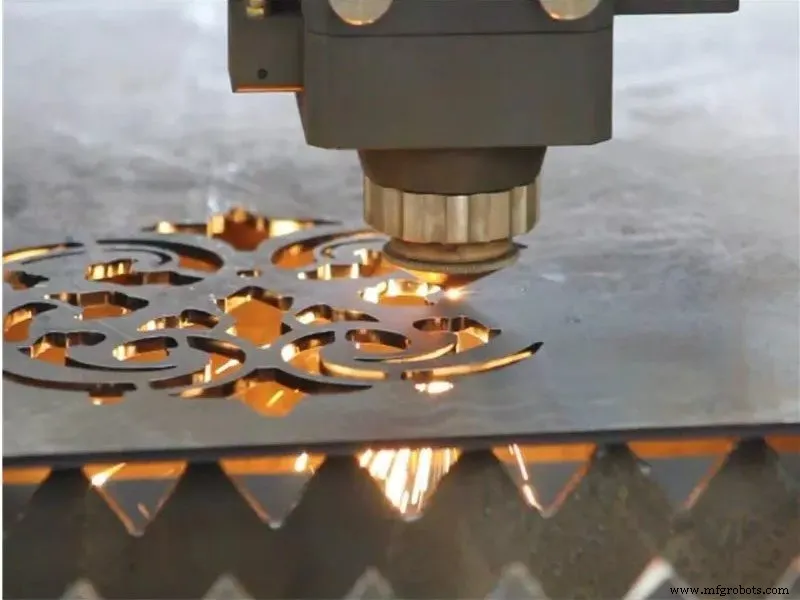

Imagine a world where raw sheets of metal are transformed with light, where industrial processes merge with artistry, and where speed, точность, and innovation converge to redefine possibilities. This isn’t a dream—it’s the reality of metal cutting laser machines, the unsung heroes driving progress across industries. From intricate designs to heavy-duty applications, these machines have become indispensable for anyone seeking precision, эффективность, and creativity.

1.What is a Metal Cutting Laser Machine?

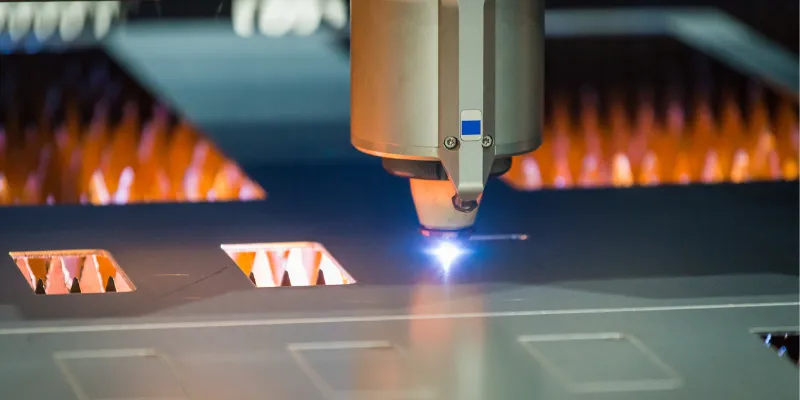

A metal cutting laser machine is a device that uses concentrated light energy to cut, форма, or engrave metal surfaces. It operates by directing a high-intensity laser beam onto the material, vaporizing or melting it to produce clean, точные разрезы. These machines are equipped with advanced controls, making them versatile for various applications, from industrial manufacturing to decorative art.

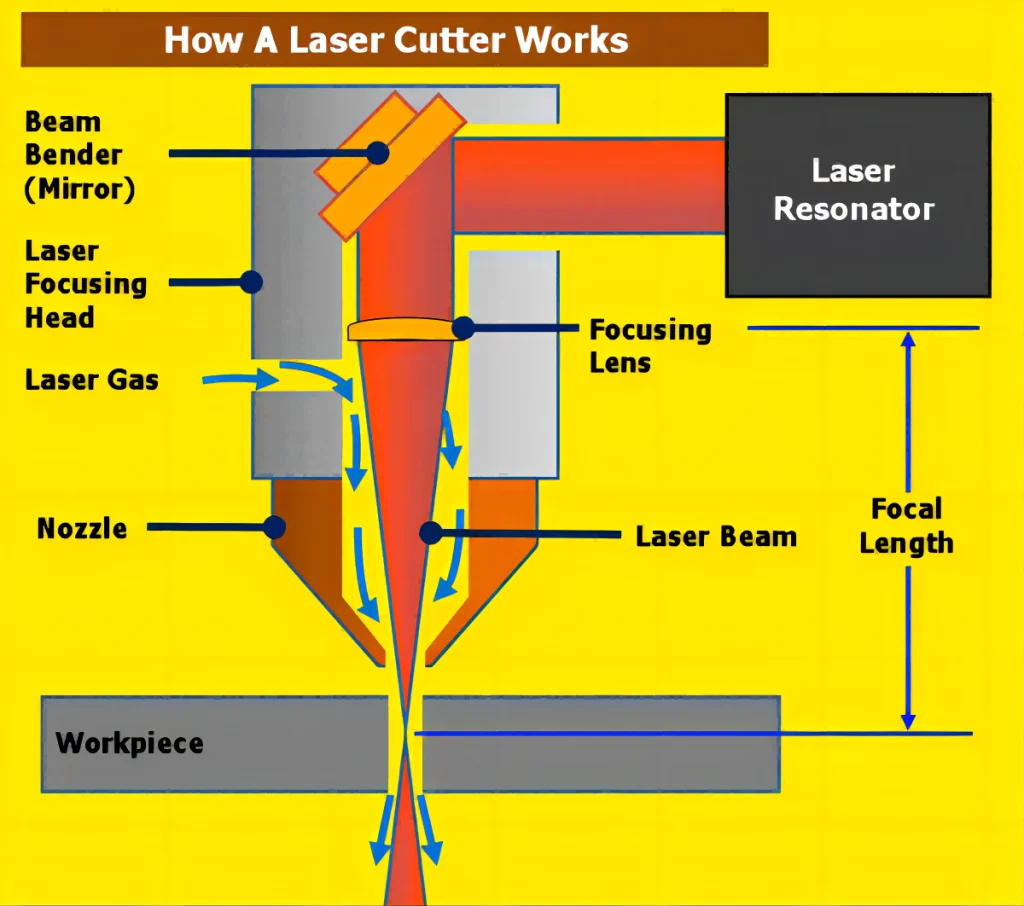

Key components of a metal cutting laser machine include:

1. Лазерный источник: Generates the high-powered beam.

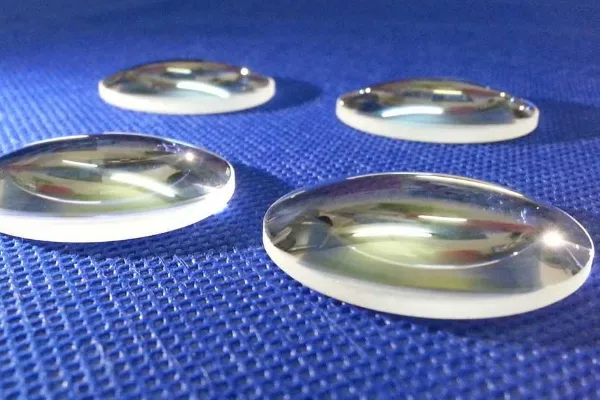

2. Optical System: Focuses and directs the beam with pinpoint accuracy.

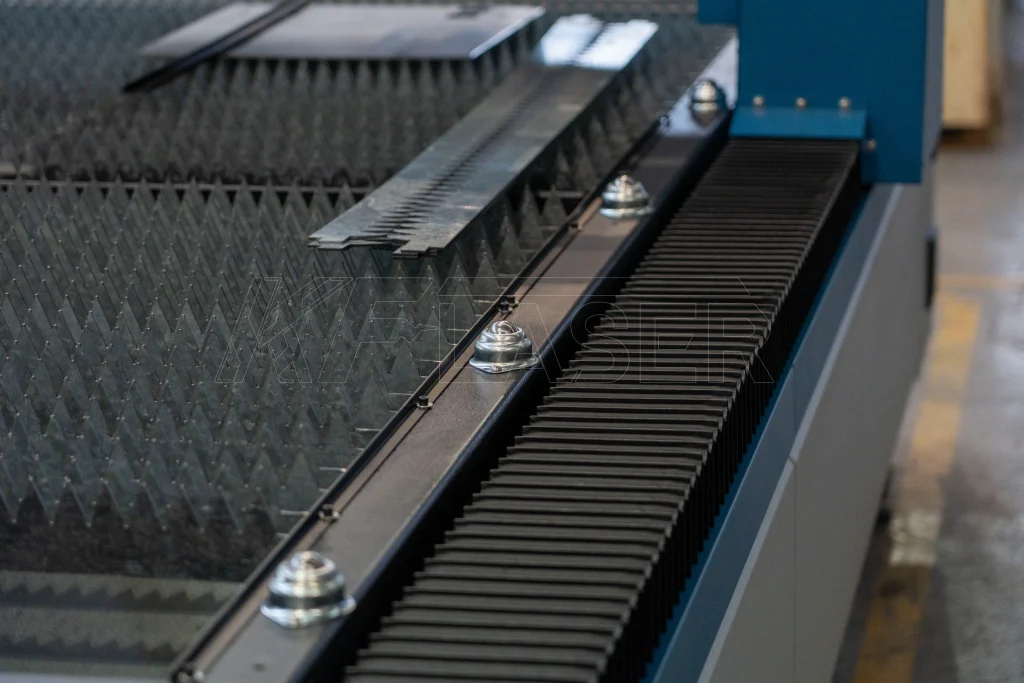

3. Cutting Bed: Holds the material in place during the process.

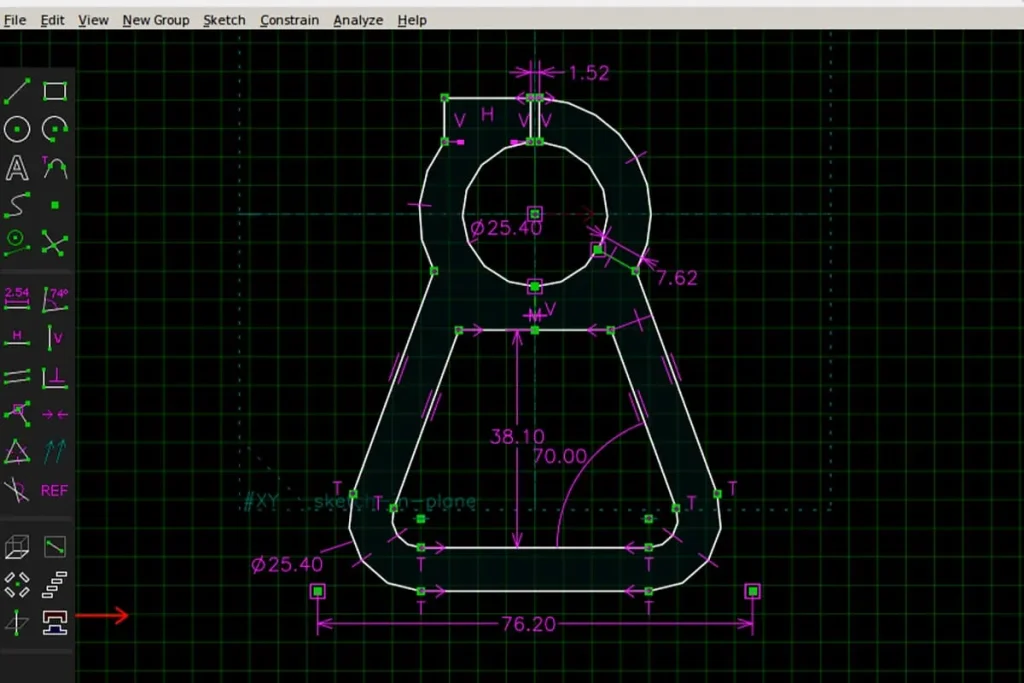

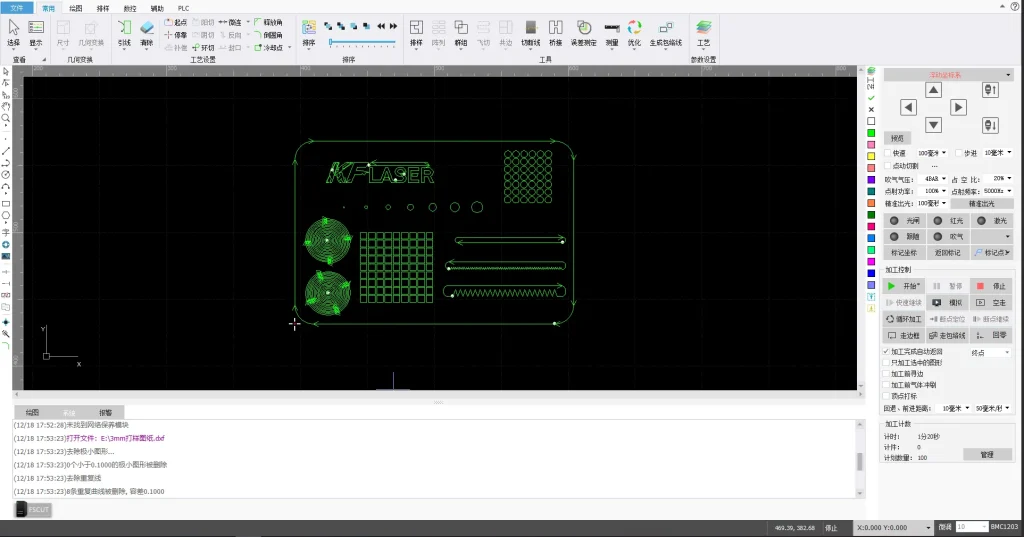

4. Программное обеспечение управления: Guides the laser path and optimizes cutting parameters.

2.Why Metal Cutting Laser Machines Stand Out

1. Precision Beyond Traditional Methods

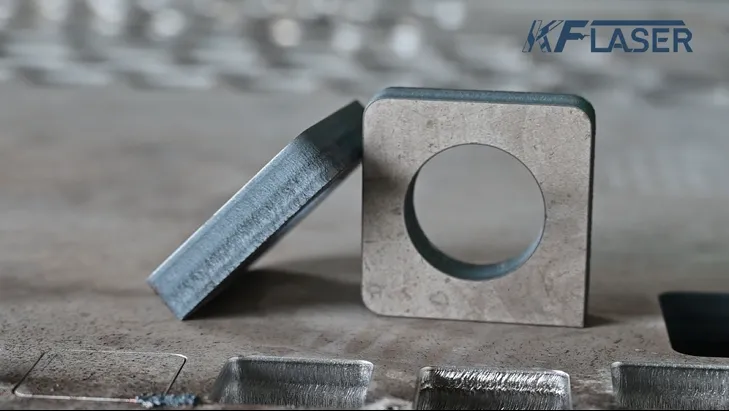

Laser cutting delivers unmatched accuracy. Whether crafting intricate patterns or producing industrial-grade parts, these machines can achieve tolerances as tight as a few micrometers. The level of detail possible with a metal cutting laser machine surpasses traditional methods like plasma or mechanical cutting.

2. Скорость и эффективность

With their ability to cut at high speeds without compromising quality, laser machines streamline production processes. This efficiency is particularly advantageous for businesses handling large-scale projects or tight deadlines.

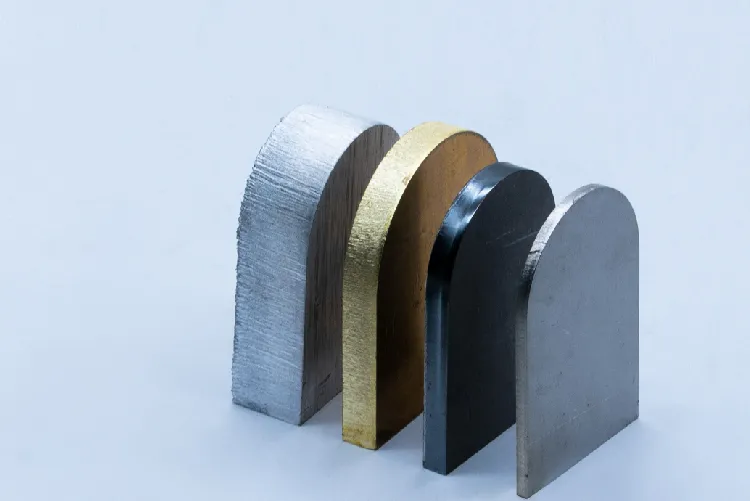

3. Материальная универсальность

Metal cutting laser machines can handle a wide variety of materials, включая:

– Нержавеющая сталь

– Алюминий

– Углеродистая сталь

– Медь

– Латунь

This versatility allows them to meet the demands of industries ranging from automotive to aerospace and construction.

4. Устойчивое развитие

Laser cutting minimizes material waste by delivering precise cuts and optimizing sheet usage. Кроме того, these machines are energy-efficient compared to other cutting methods, aligning with modern sustainability goals.

5. Снижение затрат на техническое обслуживание

Unlike mechanical tools, laser cutting systems don’t experience wear and tear from physical contact with materials. This reduces downtime and lowers long-term maintenance expenses.

3.How Metal Cutting Laser Machines Work

1. Generating the Laser Beam

The process begins with a laser source, such as a fiber or CO2 laser, which produces a focused beam of high-intensity light. The beam is directed through a series of mirrors or fiber optics to the cutting head.

2. Focusing the Beam

The laser passes through a lens that concentrates it into a fine point, generating the heat required to melt or vaporize the metal.

3. Cutting with Precision

As the laser moves along the material’s surface, assist gases like nitrogen or oxygen blow away molten metal, ensuring a clean and polished cut.

4. Guided by Software

Advanced CNC (Компьютерное числовое управление) systems guide the laser path with precision, enabling the machine to replicate complex designs accurately.

4.Applications of Metal Cutting Laser Machines

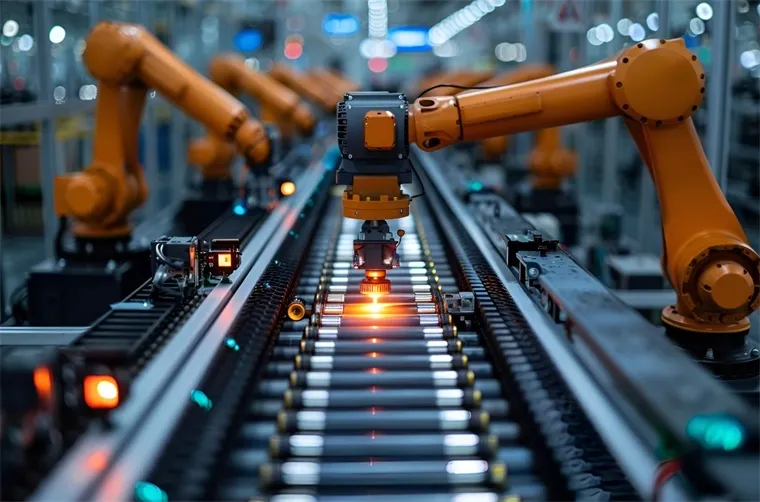

1. Автоматизированная индустрия

Metal cutting laser machines play a crucial role in producing lightweight yet durable components, such as chassis parts, engine brackets, и выхлопные системы.

2. Аэрокосмическая и защита

В аэрокосмической отрасли, precision and material integrity are paramount. Laser machines excel at creating components like turbine blades, structural supports, and fuselage panels.

3. Строительство и Архитектура

From building facades to custom decorative panels, metal cutting lasers enable architects and builders to craft functional and aesthetic designs with ease.

4. Производство электроники

Laser cutting ensures precision in creating components like heat sinks, вложения, and connectors for electronic devices.

5. Art and Customization

Artists and designers use laser cutting machines to create unique sculptures, Сложные украшения, and personalized metal decor.

6. Промышленное производство

Metal cutting lasers are indispensable in producing machinery parts, tools, and structural components for heavy industries.

5.Types of Metal Cutting Laser Machines

1. Волоконные лазеры

Fiber laser machines are known for their efficiency and ability to cut reflective materials like aluminum and brass. They are the go-to choice for high-speed production and intricate designs.

2. CO2-лазеры

CO2 lasers are ideal for cutting non-metallic materials but are also capable of handling certain metals. They are often used for decorative and artistic applications.

3. Hybrid Lasers

These machines combine the strengths of fiber and CO2 lasers, offering versatility for cutting both metals and non-metals.

4. High-Powered Industrial Lasers

Designed for heavy-duty applications, these machines can cut thick metals with ease, making them suitable for construction and large-scale manufacturing.

6.Key Features to Consider When Choosing a Metal Cutting Laser Machine

1. Выходная мощность

The power of the laser determines its ability to cut through different thicknesses. High-powered lasers are essential for cutting thick metals, while lower-powered options suffice for thinner materials.

2. Скорость резания

Evaluate the machine’s cutting speed to ensure it meets your production needs, especially for large-scale projects.

3. Совместимость материалов

Choose a machine that can handle the metals you work with most frequently.

4. Программное обеспечение и системы управления

Advanced software ensures precise cuts, easy customization, and efficient operation.

5. Обслуживание и поддержка

Partner with a trusted provider like KF LASER to ensure reliable customer support and minimal downtime.

7.Advantages of Laser Cutting Over Traditional Methods

KF LASER has established itself as a leader in laser cutting technology, offering systems that combine precision, эффективность, и надежность. Their machines cater to diverse industries, providing solutions tailored to specific cutting needs.

1. No Physical Contact

Laser cutting eliminates mechanical friction, reducing wear on tools and preserving material integrity.

2. Чистые края

The precision of laser cutting produces smooth, края без заусенцев, minimizing the need for post-processing.

3. High Repeatability

Once programmed, laser machines can replicate the same design consistently, ideal for mass production.

4. Минимальные отходы

The pinpoint accuracy of laser cutting ensures optimal material usage, reducing scrap and saving costs.

8.Future Trends in Metal Cutting Laser Machines

1. AI Integration

Artificial Intelligence is set to revolutionize laser cutting by enabling real-time adjustments, predictive maintenance, and enhanced efficiency.

2. Compact and Portable Designs

As technology evolves, smaller, more affordable laser machines will empower small businesses and individual creators.

3. Sustainable Practices

Future laser systems will prioritize energy efficiency and recyclability, aligning with global sustainability goals.

4. Multi-Functional Machines

Hybrid systems combining laser cutting with engraving or additive manufacturing will provide all-in-one solutions for complex projects.

9.Why Choose KF LASER Machines?

КФ ЛАЗЕР is a leader in providing advanced laser cutting solutions tailored to diverse industries. Their machines combine precision, скорость, и надежность, ensuring optimal performance for all cutting needs. With robust support and innovative designs, KF LASER empowers businesses to stay ahead in a competitive market.

10.Заключение: Light Up Your Manufacturing Process

A metal cutting laser machine isn’t just a tool—it’s a gateway to innovation, эффективность, and creativity. Whether you’re an industrial manufacturer, an artist, or an engineer, these machines unlock new possibilities for precision and design.

With KF LASER, you can harness the power of light to transform your ideas into reality. Explore the potential of metal cutting laser machines and redefine what’s possible in your industry. The future is here, and it’s laser-sharp.

Главные новости

-

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025 -

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025 -

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025 -

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025 -

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина