Noticias

Mild Steel Laser Cutting Sheets: Un avance en la fabricación de precisión

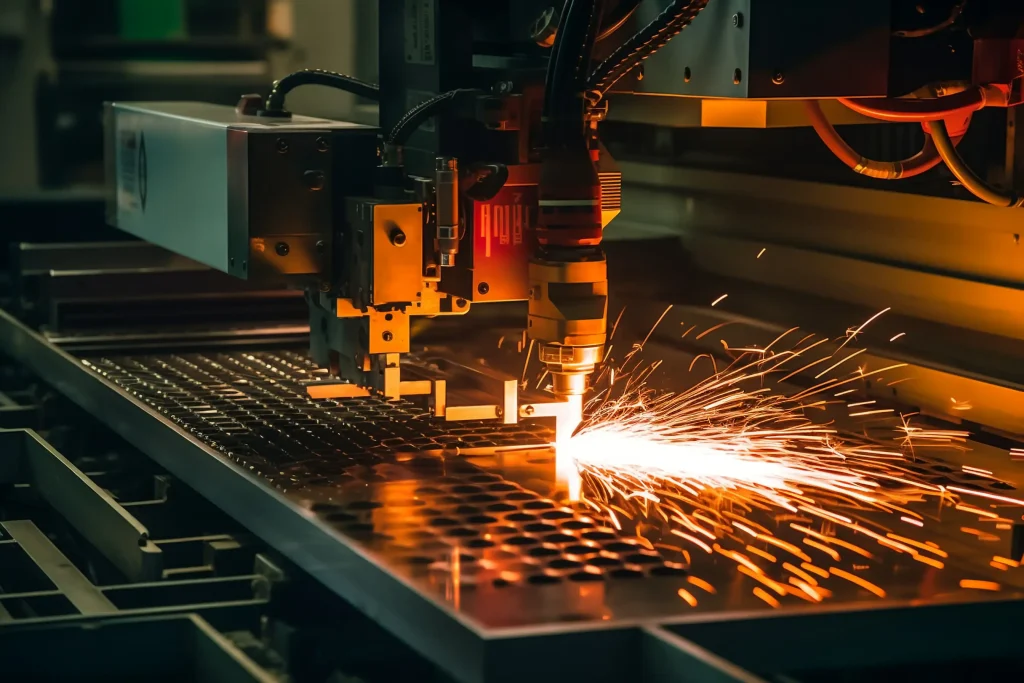

In today’s industrial landscape, the ability to cut metals with unparalleled precision is a game-changer. Mild steel laser cutting sheets are at the forefront of this revolution, offering advanced solutions for industries requiring high accuracy and speed. Whether you’re in automotive manufacturing, construcción, or any other field that demands detailed metal fabrication, understanding the nuances of laser cutting technology can unlock new efficiencies and capabilities.

What Are Mild Steel Laser Cutting Sheets?

Mild steel laser cutting sheets are precisely cut metal sheets made from mild steel using a laser cutting machine. These sheets are often used for their ability to be shaped and cut with exceptional accuracy, making them ideal for a wide variety of manufacturing processes. Laser cutting offers the advantage of clean edges, high tolerance, and minimal material wastage. The combination of these factors ensures that industries requiring precision and consistency can rely on laser cutting to meet their production demands.

Mild steel is a versatile material known for its strength and durability, making it a staple in many industrial applications. When coupled with advanced laser cutting techniques, it provides a perfect solution for both intricate designs and high-volume production.

Why Choose Mild Steel for Laser Cutting?

The properties of mild steel make it an excellent choice for laser cutting. Here are a few reasons why:

Cost-Effective: Mild steel is often less expensive compared to other metals, making it an affordable option for large-scale production.

Versatilidad: It can be used across a wide range of industries, from structural components to automotive parts.

Ease of Fabrication: Mild steel is easier to cut, bend, and weld, which is essential for high-precision projects.

Resistencia y durabilidad: Despite being relatively soft compared to other metals, mild steel still offers good strength for structural applications.

These properties ensure that mild steel laser cutting sheets remain an essential part of manufacturing, contributing to the efficient production of metal components.

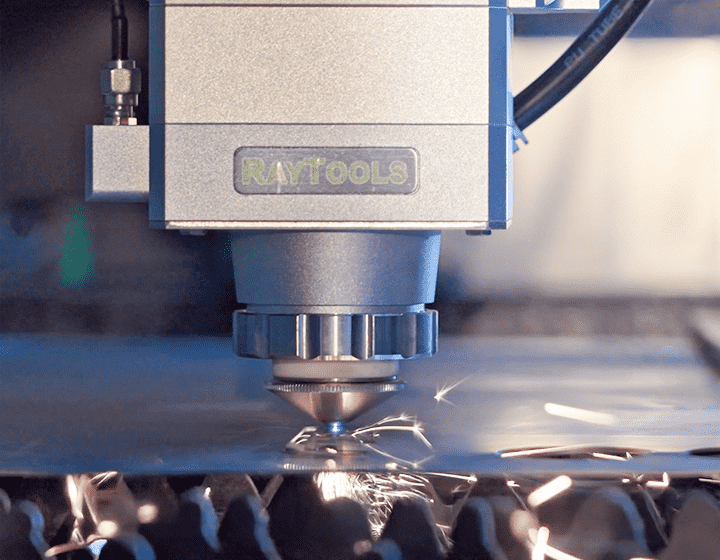

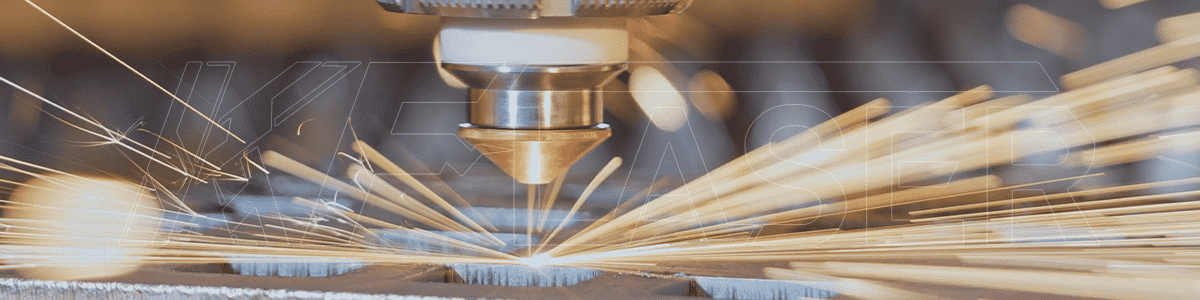

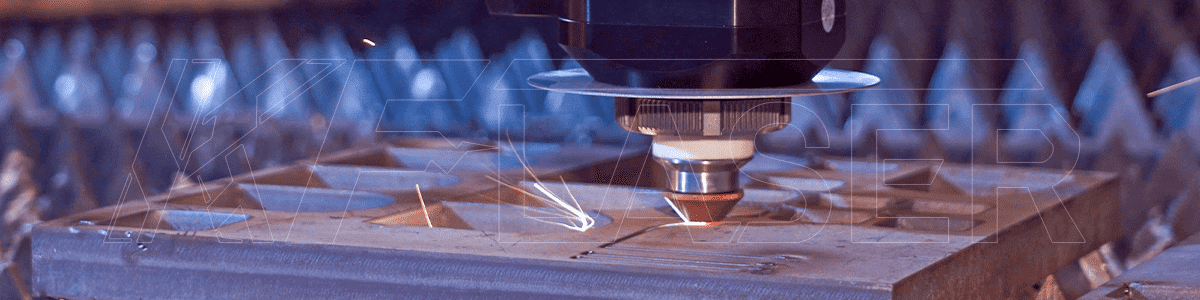

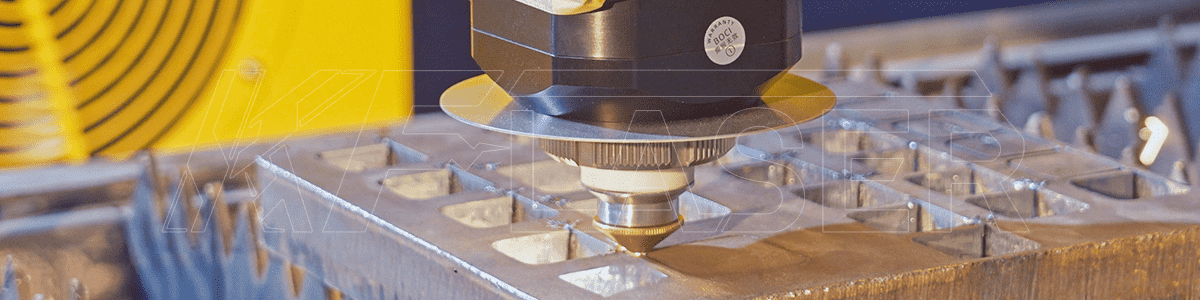

The Laser Cutting Process Explained

Laser cutting is a highly sophisticated process that uses a laser to focus intense heat on a material, effectively melting, incendio, or vaporizing it to create precise cuts. The steps involved typically include:

Preparation: The metal sheet is loaded into the laser cutting machine. The exact measurements and design are inputted into the computer system.

Laser Beam Application: The laser beam is directed at the mild steel sheet, where it begins to cut through the material with incredible precision.

Finishing: After the cutting process, the mild steel sheet is removed, and any rough edges are smoothed out for a clean finish.

This method is highly efficient, reducing time and material waste compared to traditional cutting techniques.

Key Benefits of Using Mild Steel Laser Cutting Sheets

Precisión y exactitud: Laser cutting ensures that every cut is as precise as the design dictates, with minimal deviation.

Producción de alta velocidad: The laser cutting process is faster than traditional mechanical cutting methods, allowing for quicker turnaround times.

Desperdicio mínimo: The precision of the cut means that there’s very little excess material left over, making the process highly efficient.

Flexibility: Laser cutting is ideal for creating intricate patterns and shapes that may be difficult to achieve using other methods.

Clean Edges: The laser’s heat ensures that the edges of the cuts are smooth, reducing the need for additional finishing.

Applications of Mild Steel Laser Cutting Sheets

From small-scale custom jobs to large industrial applications, mild steel laser cutting sheets are used in many sectors. Some common uses include:

Industria automotriz: Laser cutting is used to manufacture automotive parts like chassis, paneles de cuerpo, and exhaust components, where precision is critical.

Construcción: Steel beams and plates are cut to exact specifications, reducing the need for further fabrication work.

Metal Art: Artists use laser-cut mild steel sheets to create intricate designs and sculptures, showcasing the versatility of the material.

Fabricación de productos electrónicos: Laser cutting is essential for creating metal housings for electronic devices, ensuring exact dimensions for perfect fitment.

The versatility of mild steel laser cutting sheets means that their applications are vast and varied, offering solutions for nearly every sector of metal fabrication.

The Future of Mild Steel Laser Cutting Sheets

A medida que la tecnología continúa evolucionando, so does the world of laser cutting. The future of mild steel laser cutting sheets looks promising, with advancements in cutting speed, precisión, and material handling capabilities. Emerging technologies, such as fiber lasers and automated systems, are pushing the limits of what can be achieved with laser cutting.

With the continuous development of new technologies, industries will continue to adopt laser cutting as the preferred method for precision metal fabrication. Además, as industries strive for more sustainable practices, the minimal waste and energy efficiency of laser cutting will become increasingly important.

Conclusión: The Power of Mild Steel Laser Cutting Sheets

En conclusión, the use of mild steel laser cutting sheets offers a wide array of advantages, from cost-effectiveness to precision and minimal waste. This cutting-edge technology is revolutionizing how industries approach metal fabrication, ensuring high-quality results while maintaining efficiency. Whether you’re in automotive, construcción, or any other sector requiring precision metalwork, the power of mild steel laser cutting sheets is undeniable.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora