Noticias

La transformación del corte de tuberías con tecnología láser de fibra

In an age where manufacturing precision is paramount, pipe fiber laser cutting machines stand as a breakthrough technology that is reshaping industries worldwide. From the automotive sector to aerospace and beyond, fiber laser cutting machines are heralded for their unparalleled accuracy, eficiencia, and cost-effectiveness. This revolutionary technology is not just a trend—it’s the future of pipe cutting.

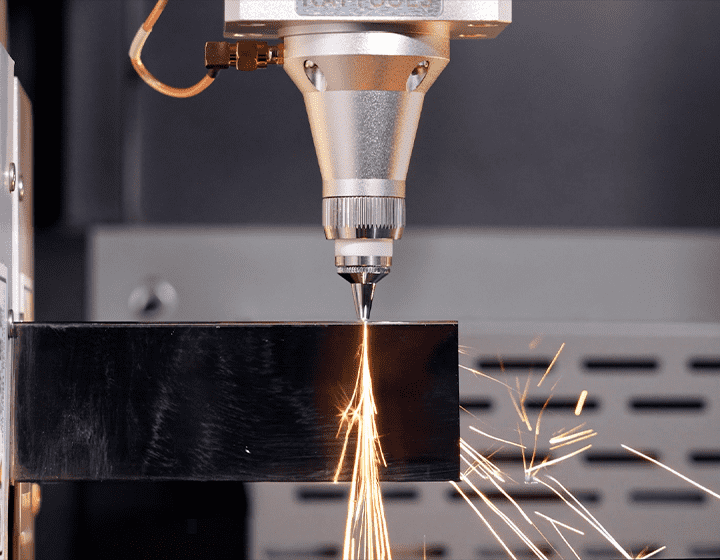

Fiber laser cutting is a sophisticated process that uses a laser beam to cut materials with precision. The advantage of using fiber lasers over traditional methods, such as plasma or mechanical cutting, is clear: fiber lasers offer higher cutting speeds, better energy efficiency, and exceptional cutting quality. This makes them the preferred choice for pipe cutting applications, where precision and cost-effectiveness are critical.

The Advantages of Using Fiber Laser Cutting Machines for Pipes

Precisión inigualable

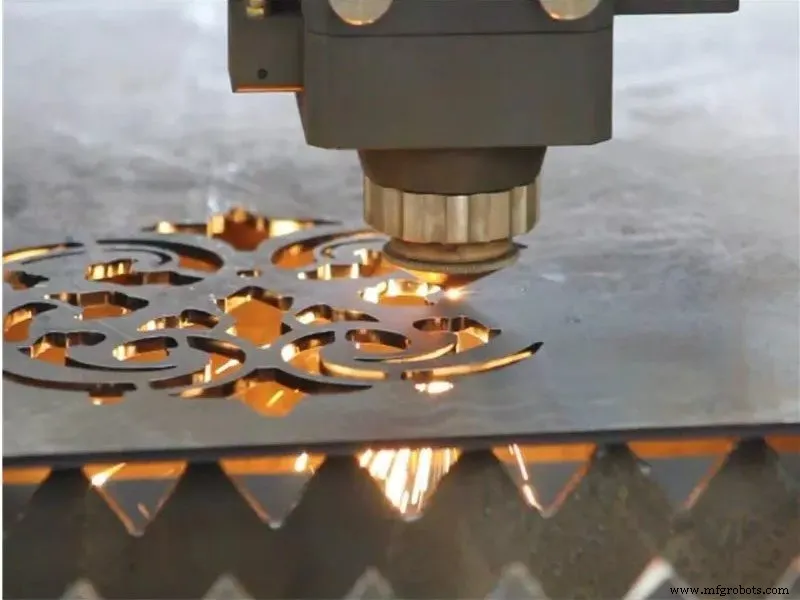

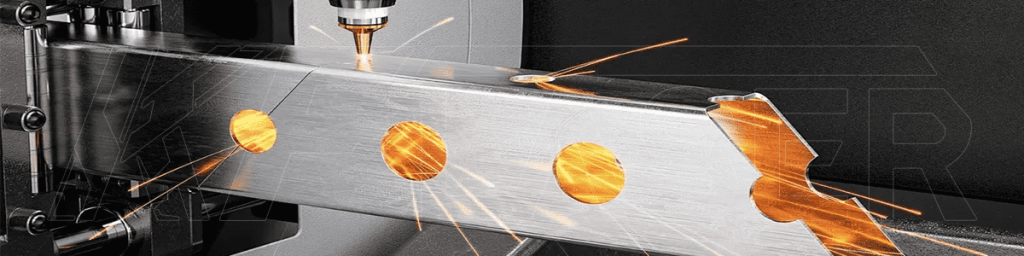

Fiber lasers provide extraordinary cutting precision, allowing manufacturers to achieve intricate designs and fine details with ease. The laser beam’s fine focus results in a smooth, clean cut with minimal material distortion, crucial for industries where tight tolerances are essential.

Increased Cutting Speed

Speed is another key benefit of using fiber laser cutting machines. Thanks to the high-powered lasers, pipes can be cut faster than traditional methods, leading to reduced lead times in production. This accelerated pace translates directly into increased efficiency and productivity for businesses.

Lower Operating Costs

Compared to older technologies, fiber laser machines have significantly lower operating costs. The energy efficiency of fiber lasers means less electricity is consumed per cut, leading to reduced energy bills. Moreover, the maintenance costs are lower since fiber lasers have fewer moving parts, minimizing wear and tear and thus increasing their lifespan.

Versatilidad en Materiales

A remarkable feature of fiber laser cutters is their ability to cut a wide variety of materials, incluyendo acero, aluminio, cobre, y acero inoxidable. For industries that require cutting different types of pipes, this versatility ensures that fiber laser machines can meet various demands without the need for multiple machines.

Reduced Waste and Clean Edges

With fiber laser cutting, the precision of the cut results in minimal material waste, making the process more sustainable. Además, the cutting edges are clean and precise, eliminating the need for secondary operations like grinding or deburring, which saves both time and costs.

Capacidades de automatización e integración

Modern fiber laser cutting machines can be integrated into automated production lines. This integration ensures that the cutting process can be seamlessly coordinated with other manufacturing operations, boosting overall system efficiency. Automation also reduces the reliance on human intervention, which minimizes the risk of errors and improves safety in the workplace.

Low Environmental Impact

With the growing focus on sustainability, fiber laser cutting machines are an environmentally friendly choice. They use less power than traditional cutting methods and produce less heat, reducing the environmental impact of manufacturing operations.

The Impact of Fiber Laser Cutting on Different Industries

The applications of pipe fiber laser cutting machines are vast, ranging across numerous industries, each benefiting from the technology’s precision and efficiency.

Industria automotriz: En la fabricación de automóviles, fiber lasers are used for cutting pipes, sistemas de escape, and chassis components with precision. The ability to handle high-strength materials like stainless steel makes fiber laser cutting ideal for the automotive sector.

Industria aeroespacial: The aerospace industry demands high accuracy and strict tolerance levels. Fiber laser cutting provides the precision required for cutting complex pipe shapes used in aircraft structures, as well as the ability to work with lightweight yet strong materials like titanium.

Oil and Gas: Pipe cutting plays a crucial role in the oil and gas industry, where efficiency and reliability are key. Fiber lasers cut through thick pipes made of tough materials, ensuring the integrity and safety of pipelines.

Construcción e Infraestructura: For large-scale construction projects, fiber laser cutting machines offer the ability to quickly and accurately cut metal pipes and structural components, improving overall project timelines and ensuring structural safety.

Overcoming the Challenges in Pipe Cutting with Fiber Lasers

While pipe fiber laser cutting machines offer numerous advantages, they are not without their challenges. One of the major considerations for businesses looking to implement fiber laser technology is the upfront cost. Fiber laser cutters can be expensive, which may deter some companies from investing. Sin embargo, the long-term savings in terms of lower operating costs and increased productivity often outweigh the initial investment.

Another consideration is the learning curve associated with adopting such advanced technology. Operators need to be adequately trained to use the fiber laser cutters to their full potential. But once this hurdle is overcome, the benefits—such as faster production cycles and less downtime—are well worth the investment.

What to Consider When Choosing a Pipe Fiber Laser Cutting Machines

If you’re considering upgrading your production line with a pipe fiber laser cutting machines, here are a few key factors to keep in mind:

Cutting Capacity: Make sure the machine is capable of handling the pipe sizes and materials that are required for your operations.

Potencia del láser: Higher power lasers are needed for cutting thicker materials. Choose a machine that provides the right power for your cutting requirements.

Facilidad de uso: Look for a machine with user-friendly software and intuitive controls, which can reduce training time and improve efficiency.

Mantenimiento y soporte: Opt for a machine that comes with comprehensive maintenance and technical support services to ensure smooth operations.

Integration Capabilities: If you’re looking to automate your production line, choose a machine that is compatible with your existing systems.

The Future of Pipe Cutting Technology

As industries continue to evolve and demand higher precision and efficiency, pipe fiber laser cutting machines are set to play an even greater role in manufacturing. Innovations in laser technology are constantly improving cutting speeds, precisión, y versatilidad, ensuring that fiber laser cutters remain at the forefront of industrial pipe cutting.

The continued development of fiber laser technology, along with its integration into fully automated systems, will likely drive the next wave of manufacturing innovations. For businesses looking to stay competitive in an ever-changing market, adopting this cutting-edge technology will be a crucial step forward.

By understanding the myriad benefits and applications of pipe fiber laser cutting machines, manufacturers can make informed decisions on how to implement this advanced technology to enhance their operations. Whether reducing costs, improving precision, or increasing efficiency, fiber lasers offer unmatched advantages that will help shape the future of pipe cutting.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora