Notícias

O guia completo para máquinas de corte a laser para aço e metal: Precisão, Poder, e versatilidade

1. Understanding Laser Cutting Machines for Steel Metal

Laser cutting machines for steel metal have become a cornerstone in modern fabrication processes, providing unparalleled precision, velocidade, e versatilidade. From automotive manufacturing to architectural applications, these machines offer the ability to cut through various grades of steel with accuracy and efficiency. This comprehensive guide explores how laser cutting machines work, their advantages, tipos, and the critical factors to consider when selecting the right machine for steel cutting applications.

Whether you’re new to laser cutting technology or looking to optimize your production capabilities, understanding the nuances of laser cutting machines for steel metal can transform your operations and deliver superior results.

Para mais informações, por favor clique https://kf-laser.com/

2. How Laser Cutting Machines for Steel Metal Work

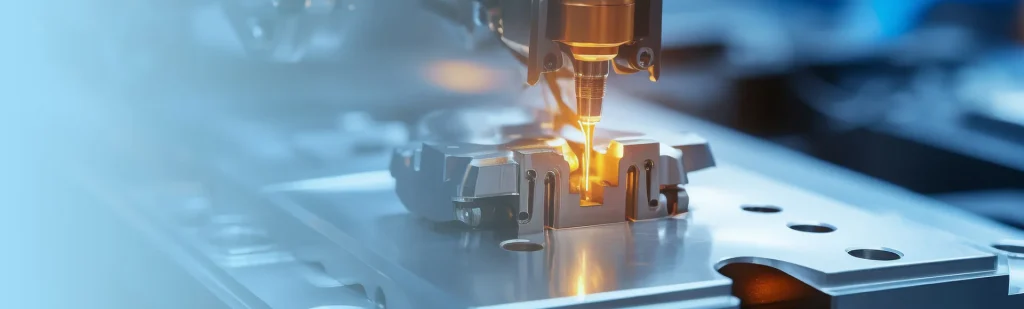

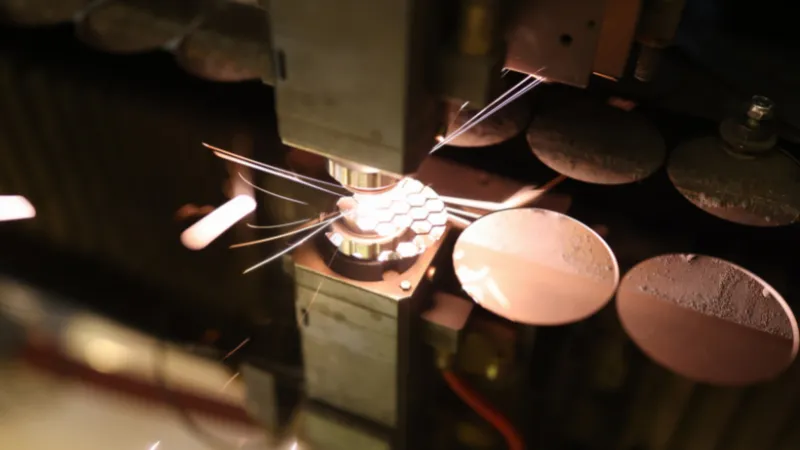

Laser cutting machines for steel metal operate by directing a concentrated beam of light onto the steel surface, generating extreme heat that melts or vaporizes the metal. This process allows for the precise shaping of steel into intricate designs without the need for traditional mechanical tools.

- Key Components of Laser Cutting Machines

– Fonte a laser: This is where the laser beam is generated, with fiber and CO2 being the two primary types used for cutting steel.

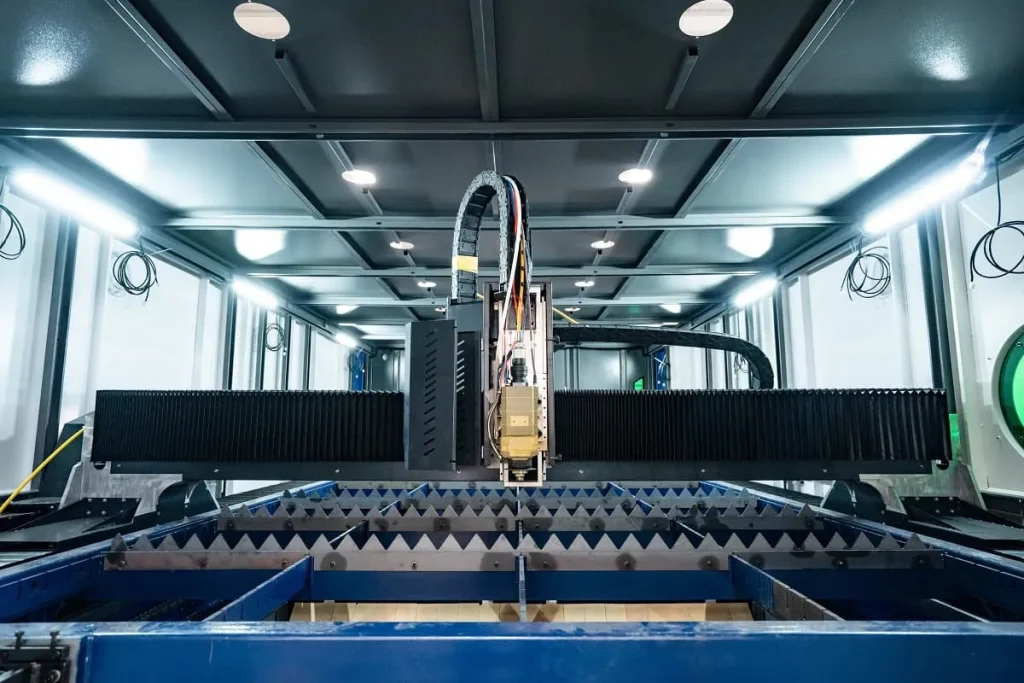

– Cabeça de corte: Houses lenses and focusing optics that direct the laser beam onto the steel surface.

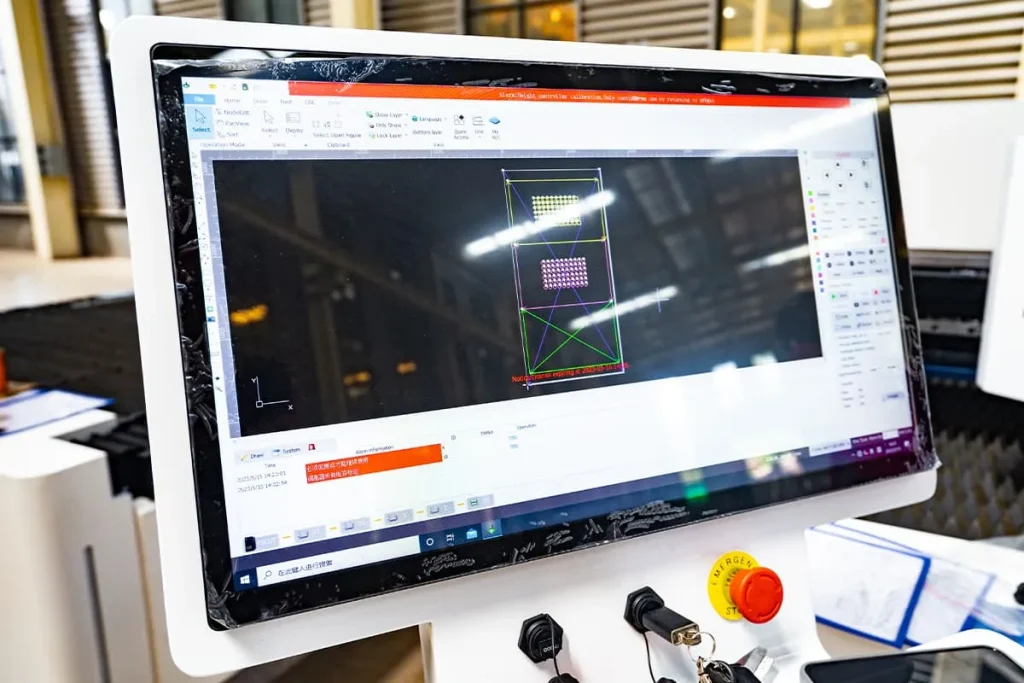

– Controlador CNC: This computer-based system guides the cutting head along the desired paths, ensuring precise cuts based on pre-loaded designs.

– Sistema de gás auxiliar: Gases like nitrogen or oxygen are used to clear away molten metal and improve the quality of the cut.

– Sistema de resfriamento: Maintains optimal temperatures for the laser source and cutting head, preventing overheating during prolonged operations.

- The Process of Laser Cutting Steel Metal

– Entrada de projeto: CAD software is used to design the shape to be cut, which is then translated into a format that the CNC controller can read.

– Material Placement: The steel sheet is secured on the cutting bed to prevent movement during the process.

– Ativação a laser: The laser is focused onto the steel, generating sufficient heat to melt or vaporize the material along the cutting path.

– Aplicação de gás auxiliar: Gases help to blow away the molten steel, ensuring a clean and precise cut.

– Conclusão de corte: The cut parts are removed and inspected for quality, followed by any necessary post-processing such as deburring.

3. Types of Laser Cutting Machines for Steel Metal

Choosing the right laser cutting machine for steel metal depends on the material’s thickness, desired precision, and production volume. The two main types of machines are fiber lasers and CO2 lasers, each with unique strengths.

Fiber laser cutting machines are renowned for their efficiency and ability to cut through various steel types with precision. Their solid-state laser source offers the following benefits:

– Precisão aprimorada: Fiber lasers produce a narrower beam, enabling highly detailed cuts that are ideal for complex designs.

– Effective for Reflective Metals: Their shorter wavelength makes them suitable for cutting reflective materials, such as stainless steel, without risk of damaging the machine.

– Energy-Efficient: Fiber lasers have a higher energy conversion rate, reducing operating costs and making them suitable for continuous, high-volume production.

- Máquinas de corte a laser de CO2

CO2 lasers use a gas mixture, typically CO2, para gerar o feixe de laser. These machines are versatile, with specific advantages in steel cutting:

– Feixe mais amplo: This wider beam is particularly useful for cutting thicker steel plates, offering a balance between speed and power.

– Smooth Edge Quality: CO2 lasers can produce smooth edges on thicker steel, minimizing the need for secondary finishing processes.

– Menor investimento inicial: Although CO2 lasers may have higher operating costs due to maintenance needs, their lower initial cost can be an advantage for some businesses.

4. Advantages of Laser Cutting Machines for Steel Metal

Laser cutting machines offer several benefits that make them ideal for working with steel metal. Here’s a closer look at why they are a preferred choice for manufacturers:

- Precisão e exatidão

Laser cutting allows for extremely tight tolerances, making it suitable for industries that require precision, como dispositivos aeroespaciais e médicos. The ability to create accurate cuts consistently ensures that parts fit together seamlessly, reducing the time spent on assembly and rework.

- Speed and Productivity

Compared to traditional cutting methods like plasma or mechanical sawing, laser cutting machines for steel metal operate at much higher speeds. This speed translates into higher productivity, allowing manufacturers to complete large production runs efficiently and meet demanding deadlines.

- Minimal Need for Post-Processing

O corte a laser produz resultados limpos, Bordas suaves, which reduces the need for additional finishing work like grinding or sanding. This not only saves time but also reduces the labor costs associated with post-processing, making laser cutting a cost-effective choice.

- Versatility Across Different Steel Grades

Laser cutting machines can handle a variety of steel grades, including mild steel, aço inoxidável, and high-strength alloys. This versatility allows manufacturers to take on a wide range of projects without needing to change equipment, providing flexibility and efficiency in production.

- Capacidades de automação e integração

Modern laser cutting machines can be integrated into automated production lines, allowing for continuous operation. Features like automated loading and unloading, nesting software, and real-time monitoring streamline the cutting process, making it easier to manage large-scale projects with minimal manual intervention.

5. Applications of Laser Cutting Machines for Steel Metal

The precision and versatility of laser cutting machines have made them essential in various industries. Here’s how they are applied in different sectors:

- Indústria automobilística

Laser cutting is used to manufacture a wide range of automotive components, from intricate engine parts to larger body panels. The precision of laser cutting ensures that each part meets the exact specifications required for optimal vehicle performance.

- Construção e Arquitetura

In the construction industry, laser cutting machines are used to create structural elements, decorative panels, and custom designs for buildings. The ability to cut steel into complex shapes allows architects and builders to realize creative designs that were previously difficult to achieve.

- Aeroespacial e Defesa

The aerospace industry requires materials that are both lightweight and strong, making high-strength steel an ideal choice. Laser cutting machines ensure that each part meets the stringent quality and precision standards required for aircraft and defense applications.

- Fabricação eletrônica

Laser cutting is also utilized in the production of steel enclosures, colchetes, and heat sinks for electronic devices. The clean cuts and precision provided by laser technology help maintain the integrity of electronic components, ensuring proper fit and function.

- Industrial Equipment and Machinery

In the manufacturing of industrial machinery, laser cutting machines are used to produce gears, quadros, and other precision components. The ability to cut thick and durable steel makes laser cutters ideal for creating robust machine parts that can withstand heavy use.

6. Choosing the Right Laser Cutting Machine for Steel Metal

When selecting a laser cutting machine for steel, it’s important to evaluate the following factors to ensure you choose the best fit for your production needs:

- Tipo de material e espessura

Different grades of steel and varying thicknesses require specific laser power settings. Fiber lasers are typically more efficient for thinner materials, while CO2 lasers may be better suited for cutting thicker steel sheets.

- Precision Requirements

If your projects demand highly detailed cuts, fiber lasers with their finer beam diameter may be the better choice. Por outro lado, if you need to cut through thicker steel plates, a CO2 laser can offer the power needed to maintain cutting speed and efficiency.

- Operating Costs

While the initial cost of the machine is a significant consideration, it’s also important to look at long-term operating costs, including energy consumption, manutenção, and replacement parts. Fiber lasers tend to have lower ongoing costs, making them a good option for businesses focused on minimizing operational expenses.

- Automation and Scalability

For manufacturers looking to scale their operations, automation features such as material handling systems and nesting software can make a significant difference. These features help reduce manual labor, improve consistency, and enable round-the-clock production.

7. Optimizing the Performance of Laser Cutting Machines

To get the most out of laser cutting machines for steel, it’s essential to optimize the machine settings and maintenance practices:

- Adjusting Laser Power and Speed

Setting the correct power level ensures that the laser can cut through the steel without causing excessive heat buildup or warping. Adjusting the speed based on the material’s thickness and the complexity of the design can improve both the cut quality and the machine’s lifespan.

- Proper Assist Gas Selection

Choosing the right assist gas—such as oxygen for faster cutting speeds or nitrogen for preventing oxidation—can significantly affect the quality of the cut. Understanding how each gas interacts with different types of steel is crucial for achieving the best results.

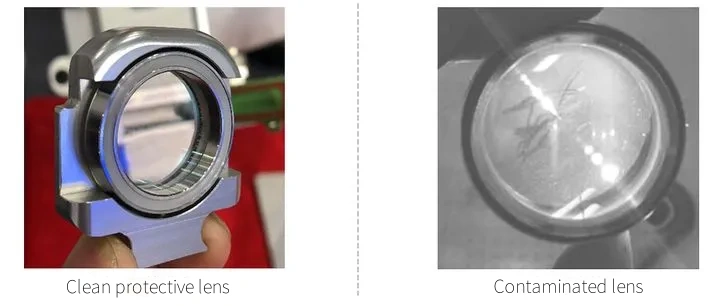

- Maintenance and Cleaning

Regularly cleaning the lenses and mirrors, checking the alignment of the laser beam, and ensuring the cooling system functions correctly are all critical to maintaining the machine’s performance. A well-maintained machine will produce better cuts and reduce the likelihood of costly downtime.

8. Emerging Trends in Laser Cutting for Steel Metal

The landscape of laser cutting continues to evolve with technological advancements, making machines more efficient and capable:

– Hybrid Machines: Combining the best features of fiber and CO2 lasers into a single unit, allowing for versatility in cutting different steel grades.

– AI-Driven Optimization: Advanced software that automatically adjusts cutting parameters based on material analysis, reduzindo o desperdício e melhorando a eficiência.

– Sustainability Innovations: New developments focus on reducing energy consumption, making laser cutting machines more eco-friendly while maintaining high productivity.

These trends highlight the potential for further enhancing the capabilities of laser cutting machines, keeping manufacturers at the forefront of industrial advancements.

Conclusões finais

Laser cutting machines for steel metal are an indispensable tool in today’s manufacturing landscape. Sua precisão, velocidade, and ability to handle various steel types make them ideal for diverse applications. By selecting the right equipment and optimizing its use, manufacturers can enhance their production processes, achieve superior quality, and meet the demands of an ever-evolving market.

Notícias principais

-

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa