Новости

Каковы недостатки волоконной лазерной резки??

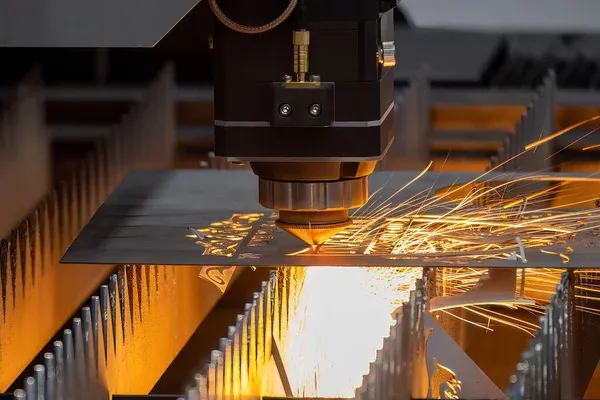

В динамичном мире производства, волоконная лазерная резка стала мощным инструментом, произвел революцию в способах обработки материалов. Представьте себе машины, разрезающие металлы с точностью хирурга., молниеносно превращать сырье в сложные конструкции. Еще, за этой блестящей внешностью скрывается ряд проблем, которые часто упускаются из виду. Пока волоконно -лазерные машины предлагают беспрецедентные преимущества, Крайне важно понимать их недостатки, чтобы принимать обоснованные решения для вашего бизнеса..

Углубляемся в нюансы технологии резки волоконным лазером, мы раскроем потенциальные недостатки этого мощного инструмента, предоставление информации, которая может помочь предприятиям эффективно ориентироваться в своей производственной среде.

1. Обзор технологии волоконной лазерной резки

- Что такое волоконная лазерная резка?

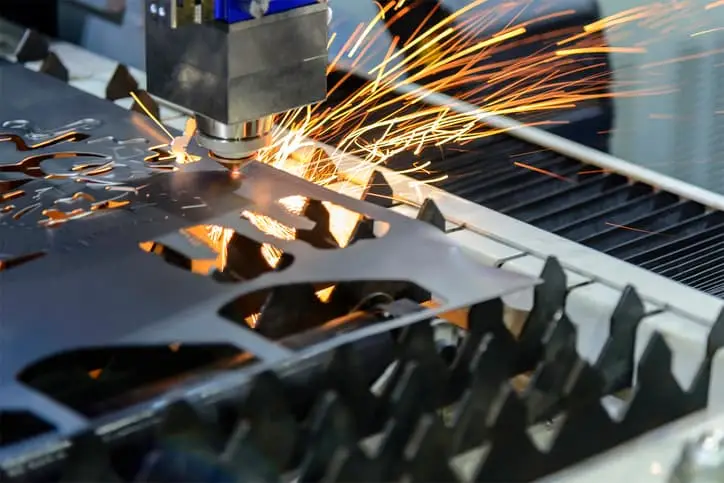

Для резки волоконного лазера используется твердотельный лазер, который генерирует луч света через оптические волокна.. Эта технология становится все более популярной благодаря своей эффективности и результативности при резке различных материалов., особенно металлы. Он известен своей высокоскоростной, высокоточная резка с минимальными потерями материала.

- Применение волоконной лазерной резки

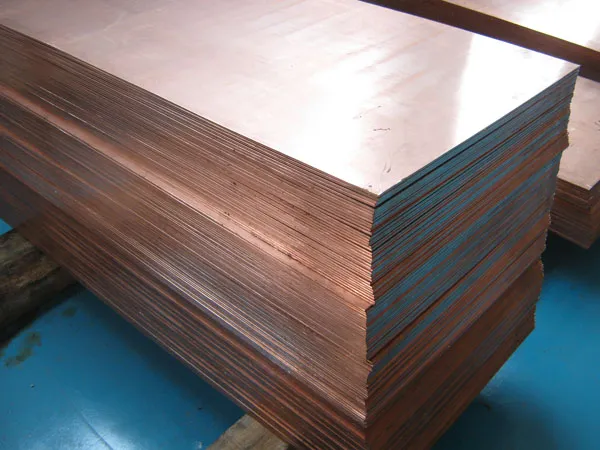

Волоконные лазеры широко используются в таких отраслях, как автомобилестроение., аэрокосмический, Электроника, и производство медицинского оборудования. Их способность резать такие металлы, как нержавеющая сталь., алюминий, и медь делают их бесценными при создании сложных деталей и компонентов..

2. Недостатки волоконной лазерной резки

Несмотря на многочисленные преимущества, Технология волоконной лазерной резки не лишена недостатков. Здесь, мы исследуем некоторые ключевые недостатки:

- Высокие первоначальные инвестиции

Одним из наиболее существенных препятствий на пути внедрения технологии резки волоконным лазером является первоначальная стоимость.. Мощные волоконные лазерные установки могут представлять собой значительную инвестицию., что может быть непомерно дорого для малого бизнеса. Хотя долгосрочная операционная экономия может компенсировать эти затраты, авансовые расходы остаются серьезной проблемой.

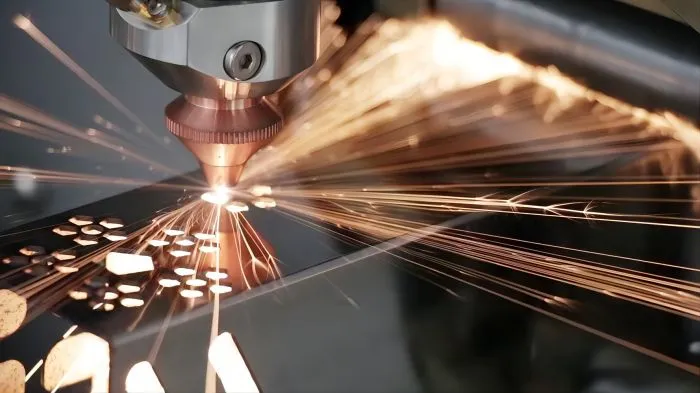

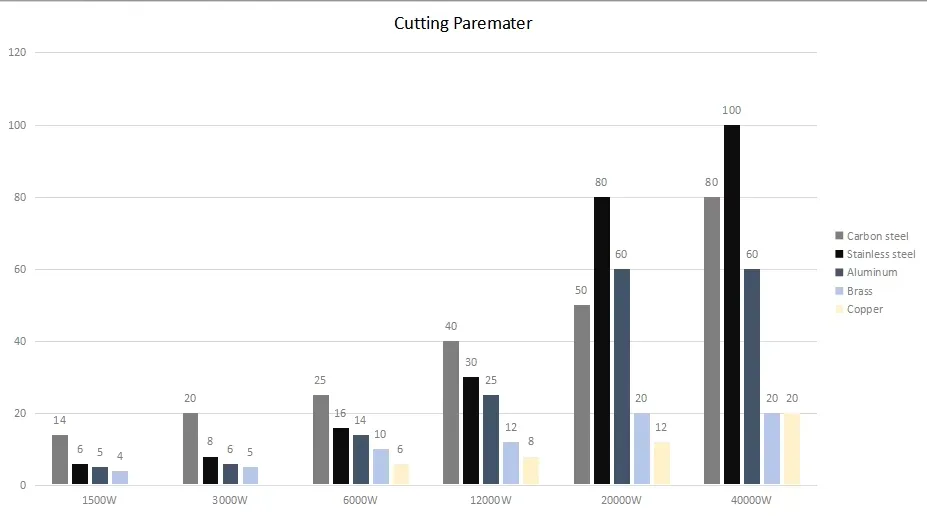

- Ограниченная толщина материала

Волоконные лазеры превосходно справляются с резкой тонких и умеренно толстых материалов., их эффективность снижается, когда речь идет об очень толстых секциях. В отличие от CO2-лазеров, который может более эффективно обрабатывать более толстые материалы, волоконные лазеры могут сталкиваться с трудностями при резке сверх определенной толщины, что может ограничить их применение в отраслях, требующих тяжелой резки..

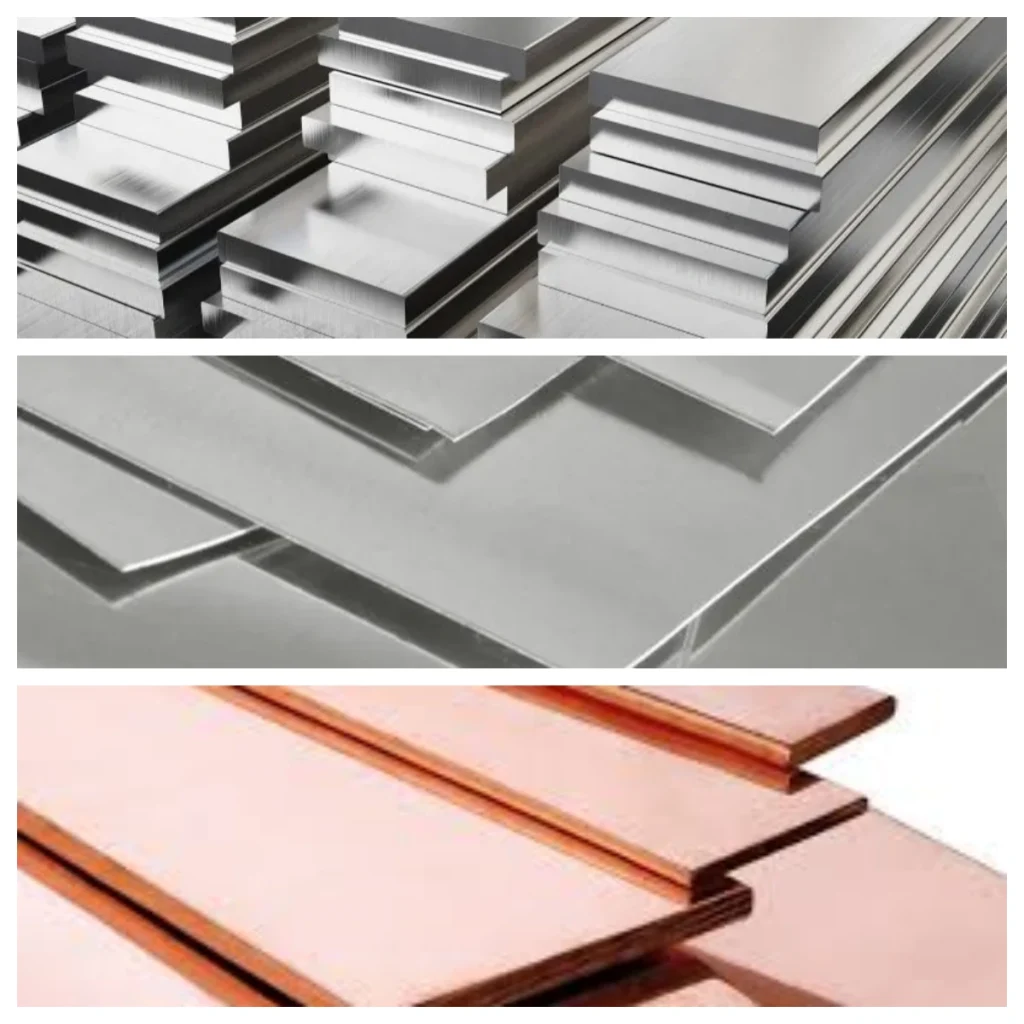

- Чувствительность к типу материала

Волоконные лазеры могут столкнуться с проблемами при резке некоторых отражающих материалов., такие как медь и латунь. Хотя они могут обрабатывать эти металлы с большей эффективностью, чем традиционные лазеры., им могут потребоваться определенные настройки и корректировки для достижения оптимальных результатов.. Эта чувствительность может привести к методу проб и ошибок во время начальных операций., влияние на производительность.

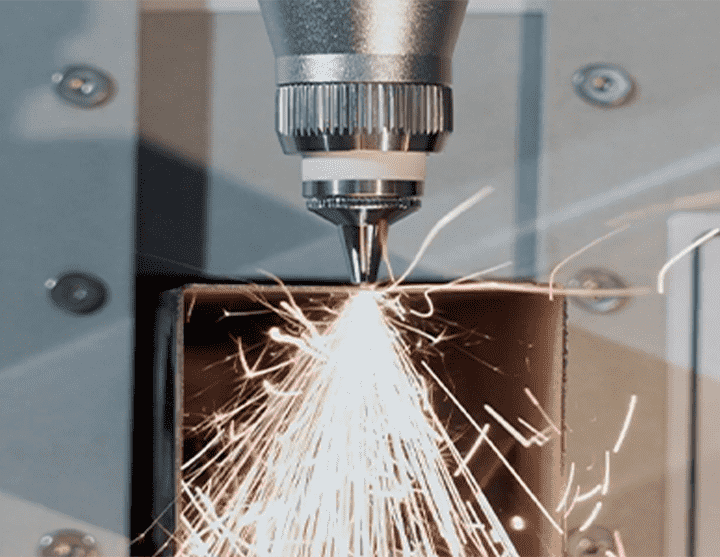

- Потенциал высокого тепловложения

Хотя волоконные лазеры предназначены для минимизации зон термического воздействия., неправильные настройки могут привести к чрезмерному выделению тепла. Это может привести к деформации, искажение, или даже горение материала, особенно в толстых секциях. Чтобы избежать этих проблем, важно поддерживать правильные настройки и обеспечивать правильную фокусировку..

- Техническое обслуживание и техническая экспертиза

Волоконные лазеры обычно требуют меньшего обслуживания, чем традиционные лазеры., они по-прежнему требуют регулярного обслуживания и проверок для обеспечения оптимальной производительности.. Кроме того, работа на станке для лазерной резки требует определенного уровня технических знаний.. Компаниям, возможно, придется инвестировать в обучение своего персонала, чтобы убедиться, что они смогут справиться со сложностями этой передовой технологии..

- Зависимость от вспомогательных газов

Для резки волоконным лазером часто используются вспомогательные газы., например, азот или кислород, для улучшения процесса резки. Потребность в этих газах может привести к дополнительным затратам и логистическим проблемам., особенно для предприятий, работающих в регионах, где эти материалы недоступны.

- Размер оборудования и требования к пространству

Станки для волоконной лазерной резки, как правило, больше, чем традиционные режущие инструменты., требующие значительной площади на производственных объектах. Для небольших мастерских или мастерских с ограниченным пространством, размещение такого оборудования может быть проблемой, потенциально влияет на рабочий процесс и эффективность.

- Ограничения в некоторых приложениях

Хотя волоконные лазеры универсальны, существуют определенные приложения, для которых они могут быть не лучшим выбором. Например, при резке некоторых пластиков или материалов, выделяющих высокий уровень дыма или паров, волоконные лазеры могут быть менее эффективными по сравнению с другими технологиями резки., например, CO2-лазеры.

3. Стратегии смягчения недостатков

Понимание недостатков резки волоконным лазером является первым шагом на пути к эффективному смягчению последствий.. Вот несколько стратегий, которые стоит рассмотреть:

- Проведите анализ затрат и выгод

Прежде чем инвестировать в технологию резки волоконным лазером, провести тщательный анализ затрат и выгод, чтобы оценить долгосрочную экономию по сравнению с первоначальными инвестициями.. Это может помочь определить, является ли данная технология жизнеспособным вариантом для вашего бизнеса..

- Инвестируйте в обучение

Обучение персонала может улучшить его понимание работы волоконного лазера., что приводит к повышению производительности и снижению рисков, связанных с неправильным обращением..

- Оптимизировать настройки

Регулярно оптимизируйте параметры резки в зависимости от типа и толщины обрабатываемого материала.. Это может помочь минимизировать тепловложение и обеспечить высокое качество резки., снижение вероятности деформации или искажения.

- Контролируйте совместимость материалов

Будьте в курсе свойств материалов и их совместимости с лазерной резкой.. Эта осведомленность может предотвратить дорогостоящие ошибки и повысить общую эффективность..

- Изучите космические решения

Если пространство беспокоит, рассмотрите возможность изменения вашего рабочего процесса, чтобы приспособить его к большей занимаемой площади станками для волоконной лазерной резки, или изучите варианты оборудования, позволяющего максимально эффективно использовать пространство..

4. Будущее технологии волоконной лазерной резки

По мере развития отрасли, то же самое произойдет и с технологией волоконной лазерной резки.. Дальнейшие достижения в области лазерной техники и материаловедения, вероятно, расширят возможности волоконных лазеров., потенциально устраняя многие из текущих недостатков.

- Повышенная мощность и эффективность

Будущие разработки могут привести к созданию еще более мощных волоконных лазеров, которые смогут эффективно прорезать более толстые материалы., расширение спектра применения в различных отраслях.

- Улучшенное обучение и поддержка

Поскольку технология волоконного лазера становится все более распространенной, производители любят КФ ЛАЗЕР ожидается, что они предложат расширенное обучение и поддержку операторов., облегчая предприятиям внедрение и оптимизацию использования этой технологии..

- Большая интеграция с автоматизацией

Интеграция станков для волоконной лазерной резки с автоматизированными системами упростит производственные процессы., что позволяет повысить производительность и снизить количество человеческих ошибок.

В навигации по производственной технологии, понимание преимуществ и недостатков резки волоконным лазером имеет решающее значение. Хотя эта мощная технология предлагает множество преимуществ, признание его ограничений позволяет предприятиям принимать обоснованные решения, соответствующие их операционным целям.. Используя сильные стороны волоконной лазерной резки и реализуя стратегии решения ее проблем., компании могут позиционировать себя для достижения успеха на конкурентном рынке.

Главные новости

-

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025 -

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025 -

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025 -

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025 -

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина