News

Laser Cut Sheet Metal: Precision and Innovation Transforming Manufacturing

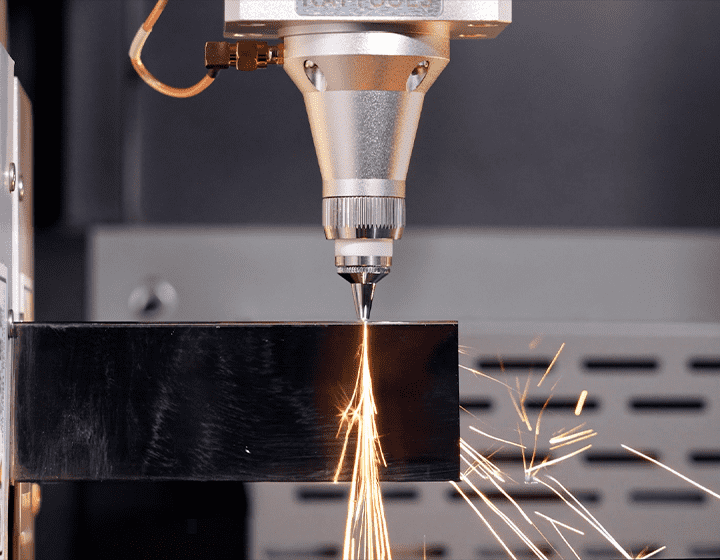

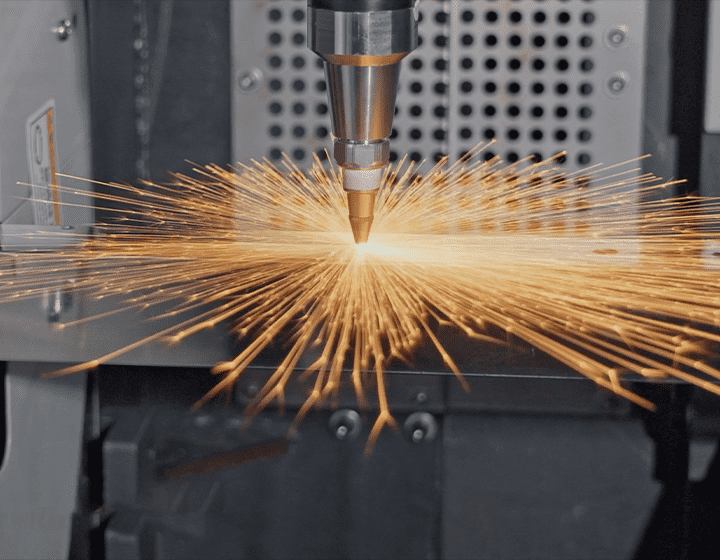

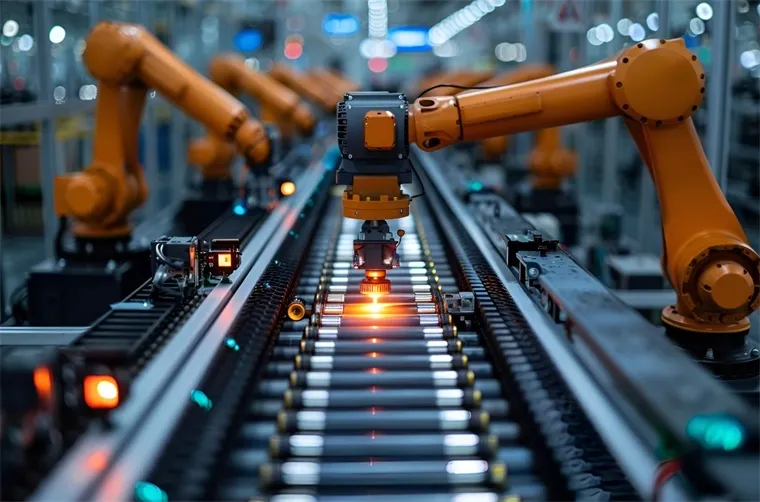

In the realm of modern manufacturing, a quiet revolution is reshaping how we design, build, and innovate. Picture intricate patterns carved with precision, durable components crafted effortlessly, and processes that blend speed with perfection. This is the promise of laser cut sheet metal, a technology that is redefining possibilities across industries. From aerospace to artistry, this method has become a cornerstone of modern production, offering unmatched accuracy, efficiency, and versatility.

KF LASER takes you into the world of laser cutting.

1.What is Laser Cut Sheet Metal?

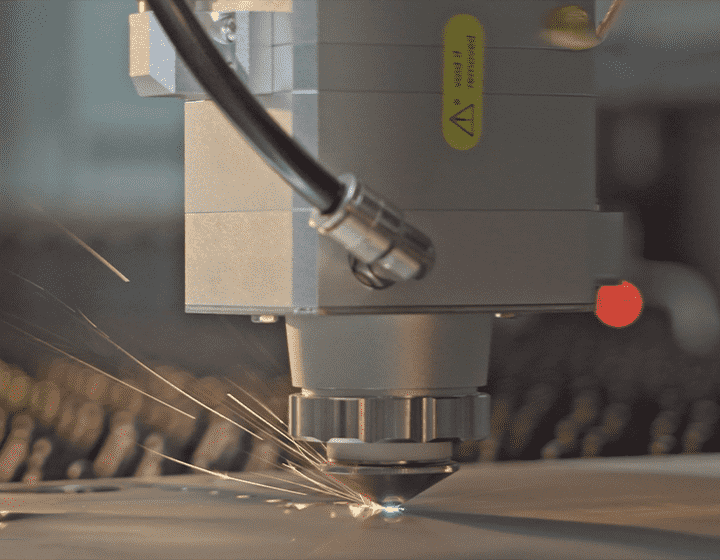

Laser cutting is a non-contact thermal process that uses a focused laser beam to melt, vaporize, or blow away material, creating precise cuts in sheet metal. Unlike traditional cutting methods, laser cutting delivers exceptional detail without physical contact, minimizing material distortion and ensuring high-quality finishes.

★ The following video can give you a clearer understanding of the cutting method of the laser cutting machine:

Sheet metal refers to flat, thin sheets of metal ranging in thickness, typically used in a wide range of applications, including automotive parts, construction materials, and custom decorative designs. Combining laser technology with sheet metal processing has opened doors to innovation, allowing industries to push the boundaries of what’s possible.

2.Why Laser Cut Sheet Metal is the Gold Standard

1. Precision Beyond Compare

When it comes to accuracy, laser cutting surpasses traditional methods. The focused beam can cut intricate designs and achieve tolerances as tight as a few micrometers. This precision is crucial for industries like aerospace, medical equipment, and electronics, where accuracy directly impacts performance.

2. Speed and Efficiency

Laser cutting dramatically reduces production times. High-powered lasers can cut through various thicknesses of sheet metal in seconds, significantly faster than mechanical methods. The automation capabilities of laser systems streamline processes, enhancing productivity.

3. Material Versatility

One of the standout features of laser cutting is its ability to handle a wide range of materials, including:

– Stainless steel

– Aluminum

– Brass

– Copper

– Galvanized steel

This versatility makes it suitable for diverse industries, from heavy manufacturing to delicate art installations.

4. Minimal Material Waste

With its pinpoint precision, laser cutting minimizes material waste, maximizing yield from each sheet. This not only reduces costs but also aligns with sustainable manufacturing practices.

5. Non-Contact Cutting

Traditional cutting methods often cause wear and tear on tools, increasing maintenance costs. Laser cutting, however, is a non-contact process, which means no physical impact on the material, resulting in smooth edges and longer machine lifespans.

3.Applications of Laser Cut Sheet Metal

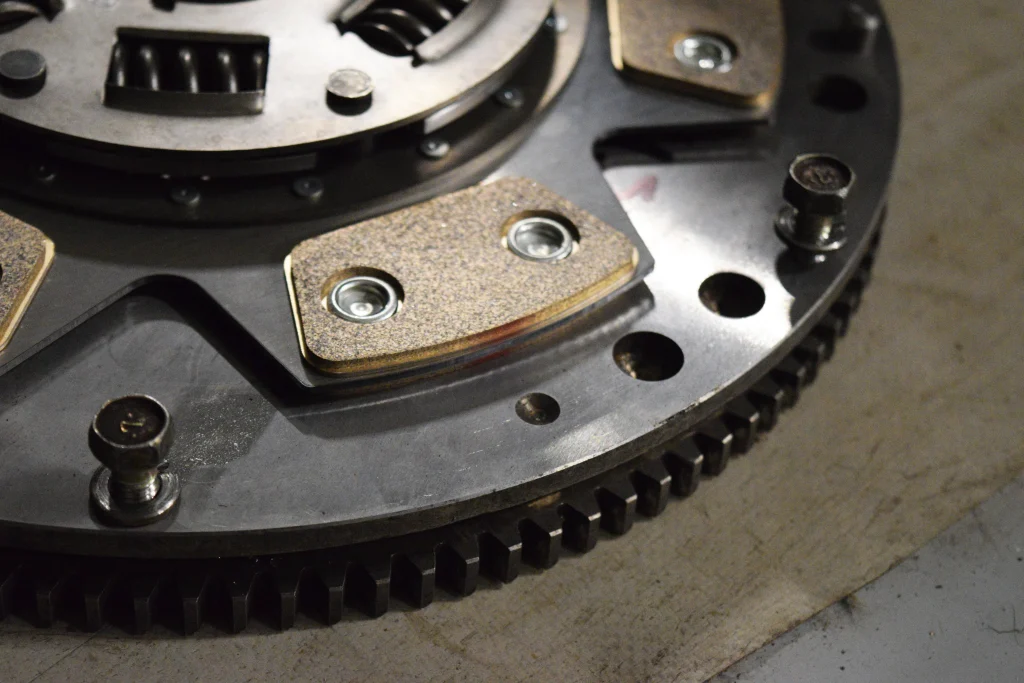

1. Automotive Industry

Laser cut sheet metal is pivotal in crafting lightweight and durable components such as chassis, panels, and brackets. Its precision ensures seamless integration of parts, enhancing vehicle performance and safety.

2. Aerospace and Defense

In aerospace, every gram matters. Laser cutting allows manufacturers to create lightweight yet strong components like turbine blades, fuselage panels, and structural supports with unparalleled precision.

3. Architecture and Design

From decorative screens and custom staircases to facades and furniture, laser cut sheet metal enables architects and designers to turn their visions into reality. The precision of laser technology ensures flawless execution of even the most complex designs.

4. Medical Equipment

Medical devices demand a high level of accuracy and hygiene. Laser cutting is used to produce surgical instruments, prosthetics, and implantable devices, meeting stringent medical standards.

5. Electronics

The electronics industry relies on laser cutting for precision and reliability in producing enclosures, circuit boards, and heat sinks.

4.How Laser Technology Enhances Sheet Metal Cutting

1. Focused Laser Beam

The concentrated laser beam delivers extreme precision, cutting through even the hardest metals with minimal distortion. The ability to focus on a tiny spot ensures intricate designs and clean edges.

2. Assist Gases

Gases like nitrogen, oxygen, and air are used in the cutting process to blow away molten material and improve cut quality. For example:

– Nitrogen: Ideal for stainless steel and aluminum, preventing oxidation.

– Oxygen: Enhances cutting speed, especially for thick materials.

3. CAD Integration

Laser cutting machines use Computer-Aided Design (CAD) software to guide the laser path, enabling complex and custom designs. This integration ensures repeatability and reduces the chance of errors.

4. Automation and AI

Modern laser systems are increasingly integrating automation and AI, allowing for real-time adjustments, predictive maintenance, and enhanced efficiency.

5.Factors to Consider When Choosing a Laser Cutter for Sheet Metal

Selecting the right laser cutting system depends on various factors, including:

1. Material Type and Thickness: Ensure the system can handle the specific metals and thicknesses you work with.

2. Power Output: Higher power is necessary for cutting thicker metals efficiently.

3. Cutting Speed: Match the machine’s speed capabilities to your production requirements.

4. Software Compatibility: Choose a machine with intuitive software that supports CAD designs.

5. Maintenance and Support: Opt for trusted providers like KF LASER to ensure reliable customer service and minimal downtime.

☟ Click to enter the homepage to learn more:

6.Sustainability in Laser Cutting: A Greener Approach

As industries prioritize sustainability, laser cutting aligns with eco-friendly practices. Its ability to minimize waste and optimize material usage reduces environmental impact. Additionally, energy-efficient laser systems consume less power compared to traditional methods, contributing to greener manufacturing processes.

7.The Future of Laser Cut Sheet Metal

1. Advanced AI Integration

Artificial Intelligence will revolutionize laser cutting, enabling smarter machines that can self-adjust for optimal performance and predict maintenance needs.

2. Expanded Material Capabilities

Future laser systems will handle more exotic materials and alloys, broadening their applicability across industries.

3. Portable Systems

As technology advances, compact and portable laser cutters will empower small-scale businesses and hobbyists.

4. Multi-Functionality

Hybrid machines combining laser cutting with additive manufacturing (3D printing) or engraving will provide all-in-one solutions for complex projects.

8.Why Choose KF LASER for Sheet Metal Cutting?

KF LASER has established itself as a leader in laser cutting technology, delivering machines that balance cutting-edge performance with user-friendly operation. Their systems are designed for precision, speed, and sustainability, catering to industries ranging from aerospace to architecture. With robust support and intuitive interfaces, KF LASER empowers businesses to achieve unparalleled results.

9.Conclusion: The Precision Revolution is Here

Laser cut sheet metal isn’t just a manufacturing technique—it’s a gateway to innovation. From intricate designs to high-performance components, this technology is redefining what’s possible in modern production. With precision, speed, and sustainability at its core, laser cutting is the ultimate choice for industries looking to stay ahead of the curve.

With KF LASER, you’re not just investing in cutting tools; you’re embracing a future of limitless possibilities. Explore the potential of laser cut sheet metal and transform your ideas into reality with unmatched precision and efficiency. The revolution has begun—be a part of it.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine