News

The Comprehensive Guide to Laser Cutting Machine Prices: Factors, Insights, and Value

★ The cost of a laser cutting machine is more than just a price tag. It’s an investment in precision, efficiency, and technological excellence. From $500 entry-level diode lasers to industrial machines costing upwards of $1,000,000, the price spectrum reflects the diverse needs of industries, hobbyists, and manufacturers alike. Understanding the intricacies of laser cutting machine pricing isn’t just about comparing numbers—it’s about comprehending what those numbers represent. Let’s dive deep into the world of laser cutting machines to uncover the secrets behind their pricing, features, and value.

1.The Fundamentals: What Determines Laser Cutting Machine Price?

1. Type of Laser Technology

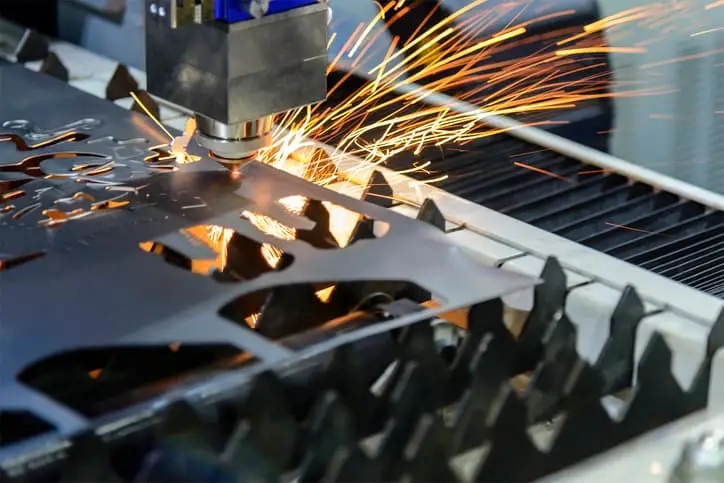

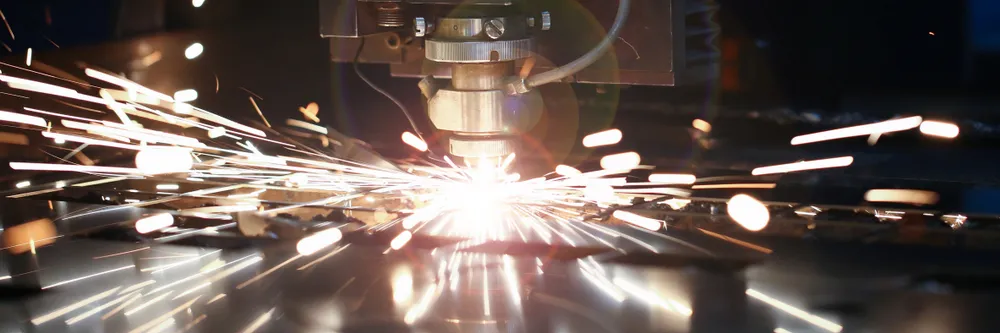

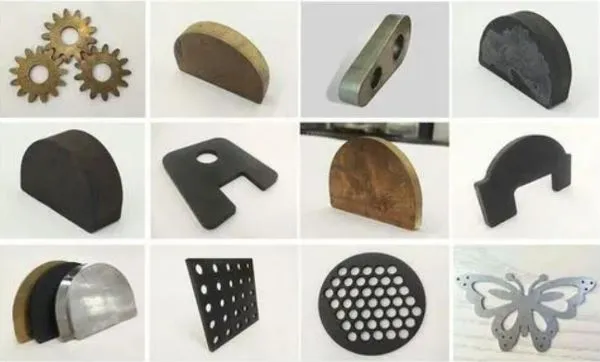

The backbone of any laser cutting machine is its laser source. The three primary types—CO2, fiber, and diode lasers—each cater to different materials, applications, and industries.

CO2 Lasers:

Best suited for cutting non-metals like wood, acrylic, and glass. These machines range from $1,000 for hobbyist models to over $100,000 for industrial setups. Their affordability and versatility make them popular in the advertising and crafting industries.

Fiber Lasers:

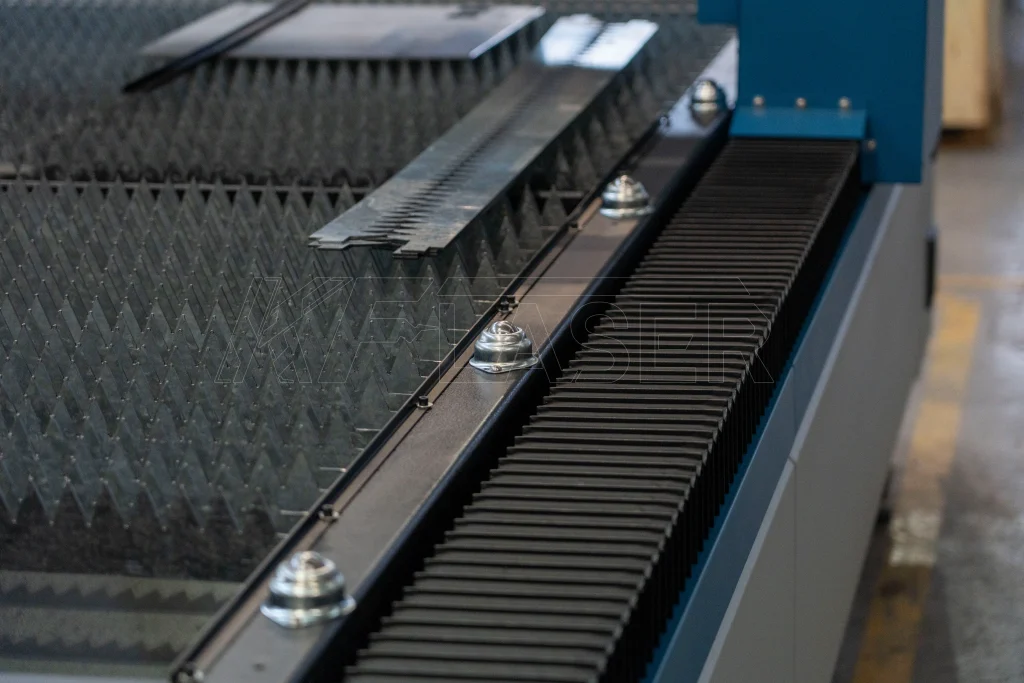

Known for their high precision and speed in cutting metals such as stainless steel and aluminum. Prices start around $3,500 for basic models and exceed $600,000 for industrial-grade machines. Fiber lasers are indispensable in automotive, aerospace, and heavy manufacturing.

Diode Lasers:

Compact and affordable, these machines excel at engraving and cutting thin materials like paper and leather. Prices range from $500 to $2,500, making them ideal for hobbyists and small businesses.

Each laser type has its advantages, and choosing the right one depends on your specific needs and budget.

2. Power Output

Laser power, measured in watts (W) or kilowatts (kW), directly impacts a machine’s cutting speed, material compatibility, and price.

Low Power (<100W):

Suitable for engraving and cutting thin materials. These machines are affordable, with prices ranging from $500 to $10,000.

Medium Power (100W – 500W):

Ideal for small businesses and light manufacturing, handling materials like wood, acrylic, and thin metals. Prices range from $10,000 to $50,000.

High Power (>500W):

Necessary for industrial applications and thick metal cutting. These machines start at $50,000 and can exceed $1,000,000, depending on additional features and capabilities.

3. Work Area Size

The size of a machine’s work area dictates the dimensions of the materials it can process. Larger work areas accommodate bigger projects but come at a higher cost.

Small Format (<600x400mm):

Found in entry-level machines for hobbyists. Prices range from $500 to $5,000.

Medium Format (600x400mm – 1300x900mm):

Common in small businesses and light manufacturing. Prices range from $5,000 to $30,000.

Large Format (>1300x900mm):

Designed for industrial applications, handling oversized materials like metal sheets and billboards. Prices exceed $30,000 and can reach $500,000.

4.Material Compatibility

Machines capable of processing a wider range of materials tend to cost more. For instance, a fiber laser that cuts metals and non-metals will generally be pricier than a CO2 laser limited to non-metals.

5. Advanced Features and Automation

Modern laser cutting machines boast features like auto-focus, material recognition, and integrated software. These add-ons enhance efficiency and precision but also increase costs. Automation systems for loading and unloading materials can add $20,000 to $100,000 to the base price.

6. Brand Reputation and After-Sales Support

Established brands like KF LASER are known for their reliability, cutting-edge technology, and excellent customer support. While premium brands may have higher upfront costs, their durability, efficiency, and comprehensive warranties often justify the investment.

2.Detailed Price Ranges for Different Laser Cutting Machines

CO2 Laser Cutting Machines

Entry-Level Models: $1,000 – $5,000 Suitable for hobbyists and small businesses, these machines handle thin non-metals like acrylic and fabric.

Mid-Range Models: $5,000 – $20,000 Ideal for small-scale manufacturing, offering higher power and larger work areas.

Industrial Models: $20,000 – $100,000+ Designed for large-scale production, capable of cutting thick non-metals and thin metals.

Fiber Laser Cutting Machines

Entry-Level Models: $3,500 – $30,000 Perfect for thin metal cutting and small-scale operations.

Mid-Range Models: $30,000 – $200,000 Common in medium-sized manufacturing, balancing power, speed, and cost.

Industrial Models: $200,000 – $600,000+ Equipped for high-speed, high-precision cutting of thick metals in industrial settings.

Diode Laser Cutting Machines

Basic Models: $500 – $1,000 Affordable and compact, ideal for engraving and light cutting tasks.

Advanced Models: $1,000 – $2,500 Suitable for small businesses needing precise, low-power cutting capabilities.

3.Total Cost of Ownership: Beyond the Purchase Price

Owning a laser cutting machine involves more than the initial investment. Let’s explore additional costs that contribute to the total cost of ownership.

1. Installation and Setup

Installation costs vary based on machine complexity and site requirements. Expect to pay $1,000 to $10,000 for professional setup.

2. Maintenance and Repairs

Regular maintenance ensures optimal performance but comes at a cost:

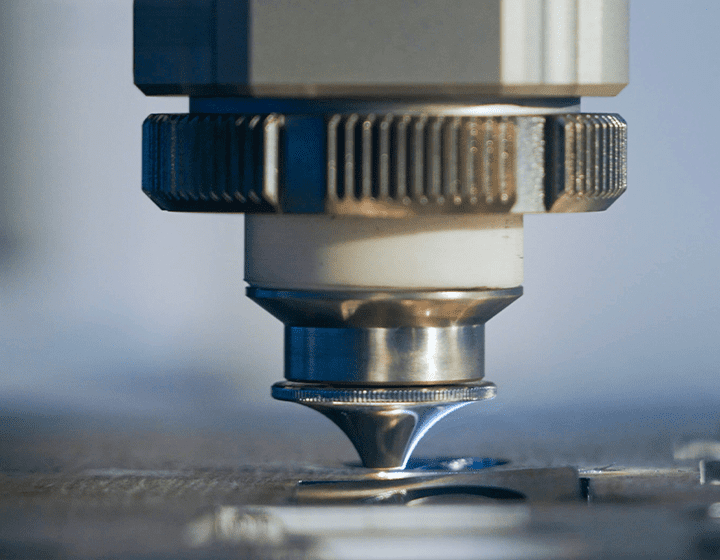

Consumables: Lenses, nozzles, and filters require periodic replacement, costing $500 to $5,000 annually.

Repairs: Component failures can cost $1,000 to $20,000, depending on the part and machine type.

3. Consumables and Assist Gases

Laser cutting requires consumables like assist gases (e.g., nitrogen, oxygen):

Gas Costs: $500 to $10,000 per month, depending on usage.

Electricity: High-power machines consume significant energy, costing $1 to $30 per hour.

4. Operator Training and Labor

Skilled operators are essential for efficient machine use. Training costs range from $500 to $5,000, and labor costs depend on local wage rates.

5. Storage and Facility Modifications

Large machines require ample space, proper ventilation, and electrical upgrades, adding $5,000 to $50,000 to your budget.

4.Tips for Maximizing Value

1. Assess Your Needs

Identify your material types, production volume, and precision requirements to choose the right machine.

2. Research and Compare

Explore multiple brands and models. Look for machines that balance cost, performance, and reliability.

3. Plan for Long-Term Costs

Consider maintenance, consumables, and energy costs to avoid unexpected expenses.

4. Leverage Promotions

Take advantage of discounts, package deals, and trade-in programs to reduce upfront costs.

5. Invest in Quality

Prioritize reliable brands like KF LASER to ensure long-term efficiency and lower operating costs.

Final Thoughts

The price of a laser cutting machine is a reflection of its technology, capabilities, and potential to transform your operations. Whether you’re a hobbyist exploring creative projects or a manufacturer optimizing production, understanding the factors influencing laser cutting machine prices empowers you to make informed decisions. With brands like KF LASER offering a range of options tailored to diverse needs, there’s a solution for every budget and application. Evaluate your requirements, plan your investment, and unlock the possibilities of precision cutting with the right laser cutting machine.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine