News

Laser Cutting Machine for Metal Sheet: Understanding Precision Cutting

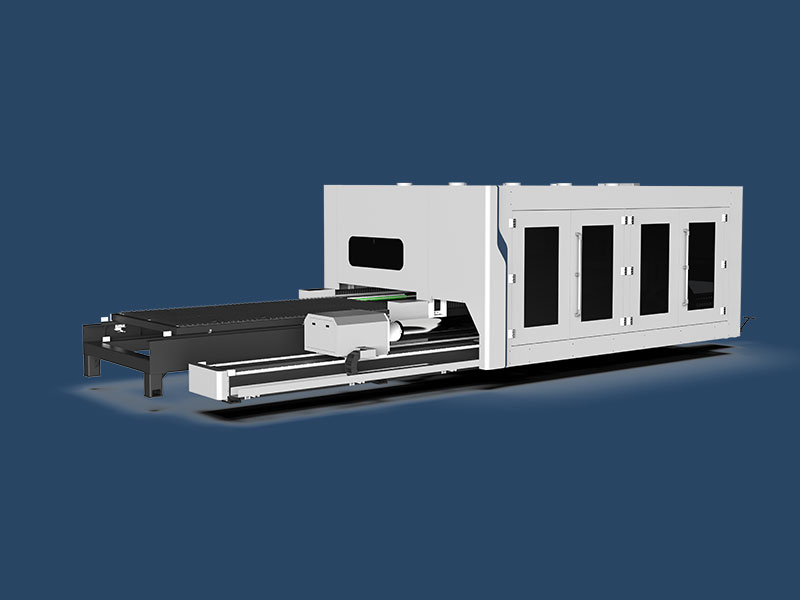

In the ever-evolving world of manufacturing, one technology stands out for its ability to offer precision, efficiency, and versatility: the laser cutting machine for metal sheet. As industries continue to demand higher levels of accuracy, laser cutting has emerged as the go-to solution for metal fabrication. Whether you’re involved in aerospace, automotive, or construction, understanding the capabilities of a laser cutting machine can help streamline production processes and ensure the highest standards of quality.

☺ You can share this article to:

1. What is a Laser Cutting Machine for Metal Sheets?

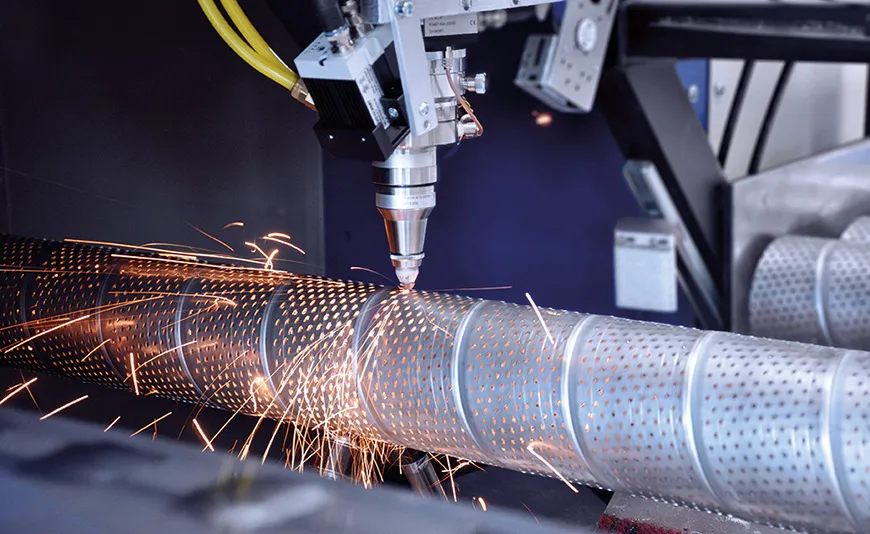

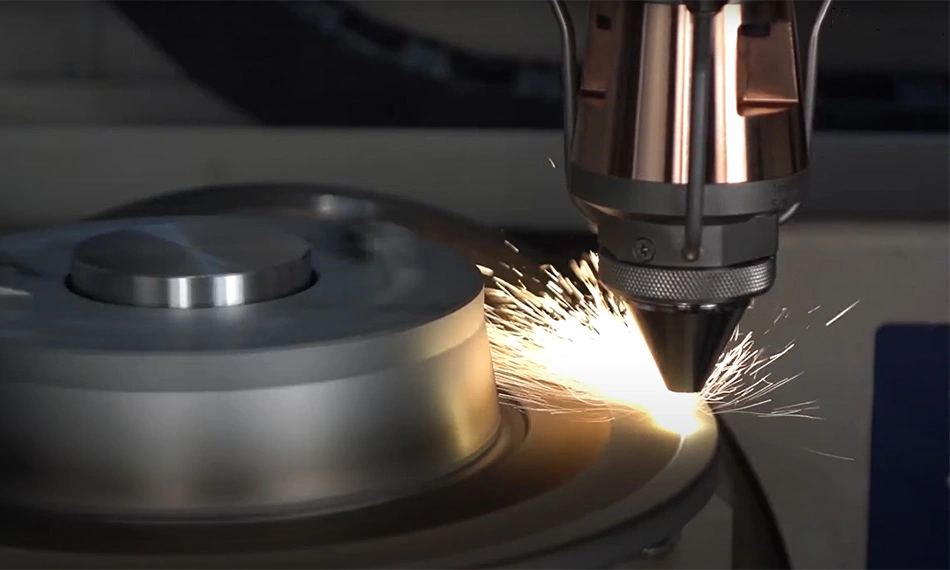

A laser cutting machine for metal sheet uses a focused laser beam to cut through various types of metals. The laser generates a concentrated heat source that melts, burns, or vaporizes the material, allowing for extremely clean and precise cuts. This technology has revolutionized the way industries approach metal cutting, offering unparalleled accuracy compared to traditional methods.

● The Laser Cutting Process

The process begins with the metal sheet being placed under the laser beam. The laser, powered by a computer-controlled system, moves across the material, following a set path to cut the metal. High-pressure gas, such as nitrogen or oxygen, is often used to assist in the cutting process, especially when cutting thicker metals, by blowing the molten material away from the cutting line.

● Types of Laser Cutting Machines

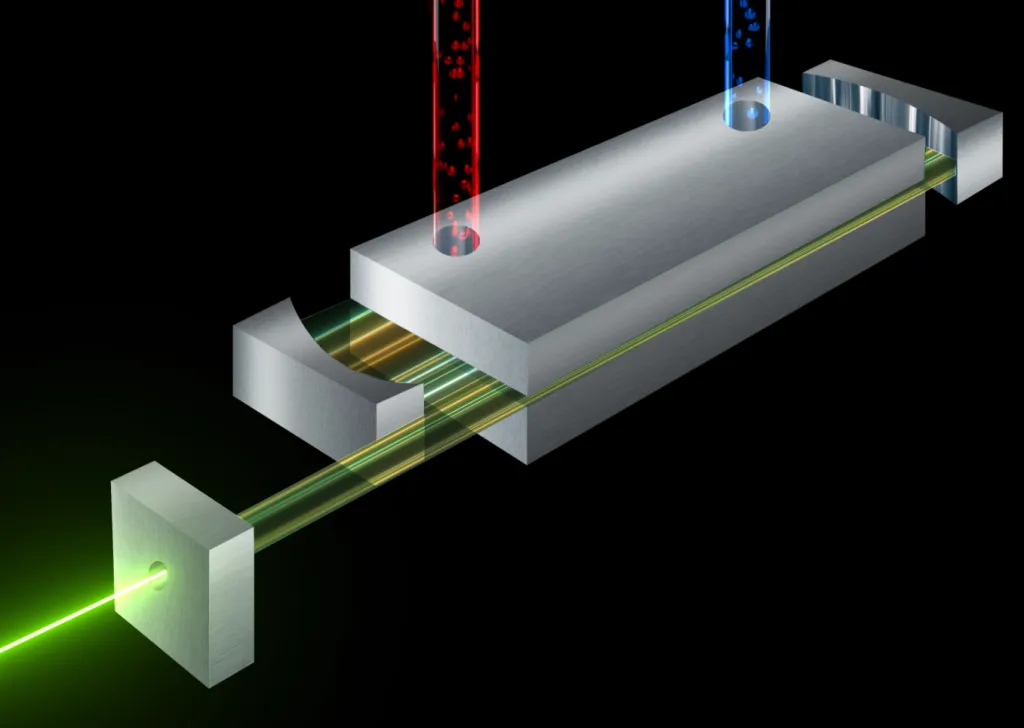

There are three primary types of lasers used for cutting metal sheets:

✔CO2 Lasers: These are the most common for cutting metals, offering a high level of power and precision, particularly in cutting thinner sheets.

✔Fiber Lasers: Known for their high energy efficiency and fast cutting speeds, fiber lasers are excellent for both thin and thick metal sheets.

✔Disk Lasers: A newer technology that offers higher cutting speeds and better energy efficiency, ideal for high-throughput applications.

Each type of laser has its strengths, making it suitable for different applications in metal fabrication.

2. Why Choose a Laser Cutting Machine for Metal Sheet?

Laser cutting is widely recognized for its numerous advantages over traditional cutting methods such as punching, shearing, or sawing. Here’s why a laser cutting machine for metal sheet is often the preferred choice:

● Precision and Accuracy

Laser cutting delivers exceptional precision, which is crucial when working with intricate designs and tight tolerances. Unlike mechanical cutting methods, laser cutting ensures that the cuts are clean and precise, with minimal deviation from the intended path. This is particularly important in industries where accuracy is paramount, such as electronics or aerospace.

● Reduced Material Waste

Laser cutting produces minimal waste, as the laser beam is extremely focused and can cut complex shapes with little to no scrap material. This efficiency helps reduce production costs, especially when working with expensive metals.

● Faster Cutting Speeds

Laser cutting machines can process metal sheets at much higher speeds than traditional cutting methods, particularly when cutting thinner metals. The speed and efficiency of laser cutting are crucial for meeting the demands of high-volume production.

● Versatility in Material Handling

While laser cutting machines are most commonly used for cutting metals like steel, aluminum, and copper, they can also handle other materials such as plastics, wood, and ceramics. This versatility makes laser cutting ideal for industries that require cutting different materials on a regular basis.

3. Laser Cutting vs. Traditional Cutting Methods

When compared to traditional cutting methods, the laser cutting machine for metal sheet offers several distinct advantages:

● No Tool Wear and Tear

Unlike mechanical cutting methods that use physical blades or dies, laser cutting does not involve direct contact with the material. This means that there is no wear and tear on the cutting tool, reducing maintenance costs and downtime.

● Cleaner Cuts with No Burrs

Laser cutting provides smoother edges with no burrs or roughness. This is especially beneficial in industries where the quality of the cut is critical, such as when the material will be used in precise assembly processes.

● More Complex Shapes

Laser cutting can easily handle intricate and complex shapes that would be difficult or impossible to achieve using traditional cutting methods. This flexibility allows for the creation of parts that are both highly functional and visually appealing.

4. Applications of Laser Cutting Machines for Metal Sheets

A laser cutting machine for metal sheet is used in a wide variety of industries and applications. Here are a few areas where laser cutting technology excels:

● Automotive Industry

Laser cutting is used extensively in the automotive industry for cutting parts such as chassis, body panels, and brackets. Its precision and ability to handle complex designs make it an essential tool in car manufacturing.

● Aerospace Manufacturing

In aerospace, laser cutting is used for producing high-precision parts that must meet strict safety standards. The ability to cut through tough metals like titanium and aluminum with minimal distortion makes laser cutting invaluable in this field.

● Electronics and Electrical Industries

Laser cutting is essential in electronics for cutting circuit boards and other components with extreme precision. It is also used for creating parts that require tight tolerances, such as connectors and heat sinks.

● Construction and Heavy Industry

In the construction sector, laser cutting is used to create structural components and components for heavy machinery. Its ability to handle thick metals like steel makes it ideal for producing parts for buildings, bridges, and other infrastructure.

5. Choosing the Right Laser Cutting Machine for Metal Sheets

Selecting the right laser cutting machine for metal sheet depends on several factors, including:

● Material Type and Thickness

Different materials require different laser types. CO2 lasers are better for thin materials, while fiber lasers excel at cutting thicker materials like stainless steel. Understanding the thickness and type of material you will be cutting is crucial when selecting a machine.

● Cutting Speed and Efficiency

For high-volume production environments, cutting speed and efficiency are crucial. High-powered lasers with faster cutting speeds will help ensure that production demands are met on time.

● Budget and Operational Costs

Laser cutting machines can be expensive, both in terms of initial investment and operational costs. Consider your budget and the long-term operational costs, including maintenance, energy consumption, and consumables, before making a purchase.

6. The Future of Laser Cutting Machines for Metal Sheets

As technology continues to evolve, the capabilities of laser cutting machines for metal sheets will only improve. New developments in laser technology, including improved fiber lasers and automated systems, promise even higher levels of precision, speed, and energy efficiency. With the increasing demand for high-quality metal parts in various industries, the future of laser cutting technology looks bright.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine