News

Fiber Laser Tube Cutting Machine: The Future of Tube Cutting

The fiber laser tube cutting machine has emerged as a powerful tool in industries that require precision and efficiency in metal tube processing. Whether it’s for automotive, construction, or manufacturing applications, fiber laser technology has revolutionized how metal tubes are cut. With faster cutting speeds, superior precision, and minimal waste, these machines are rapidly becoming the gold standard in tube cutting operations. But what exactly makes fiber laser tube cutting machines stand out in a crowded field of cutting technologies?

☺ You can share this article to:

1. What is a Fiber Laser Tube Cutting Machine?

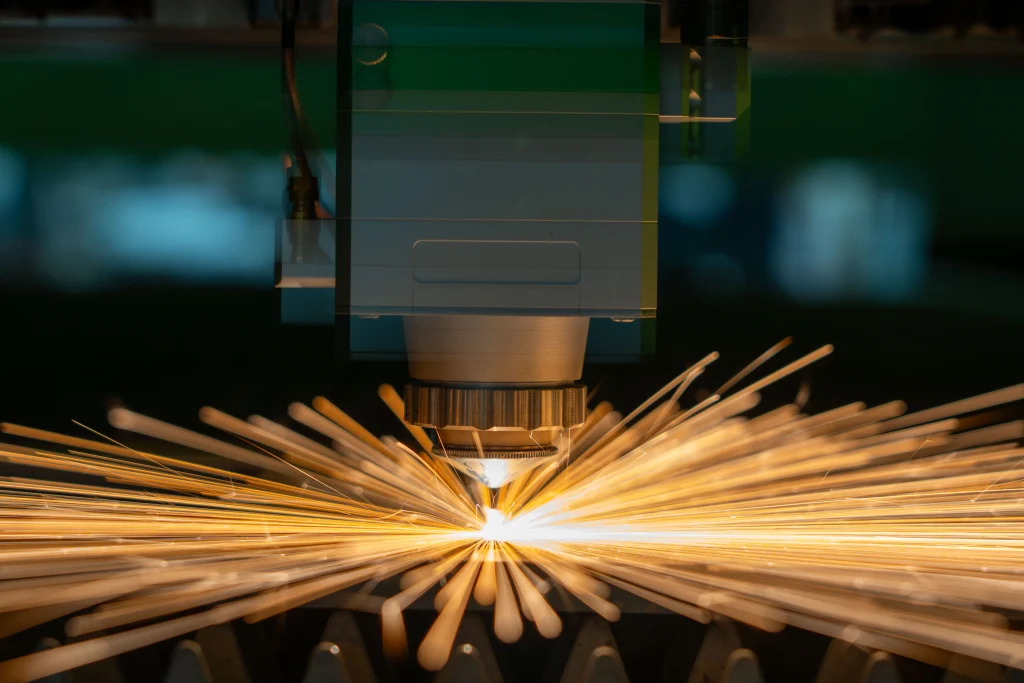

A fiber laser tube cutting machine utilizes a high-powered fiber laser beam to cut metal tubes and pipes with precision. Unlike traditional cutting methods, the fiber laser uses a solid-state laser beam that is more efficient and effective in cutting through metals with high accuracy. The beam is focused through fiber optic cables, which leads to a more concentrated energy output, resulting in faster cutting speeds and cleaner edges.

♦ The Cutting Process

The cutting process involves directing a focused laser beam onto the surface of a metal tube. As the laser interacts with the material, the tube is heated to its melting point, and the molten material is blown away by a high-pressure gas, leaving behind a clean cut. The flexibility of fiber lasers allows for intricate shapes, holes, and patterns to be cut with ease, making them ideal for both simple and complex tube designs.

☝ The above video is of KF Laser two-chuck laser tube cutting machine.

2. Benefits of Using a Fiber Laser Tube Cutting Machine

There are numerous benefits associated with using a fiber laser tube cutting machine, particularly in industries that require high precision and speed. Let’s take a look at the key advantages.

♦ High Precision and Quality

Fiber lasers offer unparalleled precision, which is crucial when working with tubes that must fit exact specifications. Whether it’s cutting intricate designs or producing parts with tight tolerances, the laser’s beam is incredibly focused, allowing for fine cuts without deformation. This results in minimal post-processing and a smoother, higher-quality finished product.

♦ Faster Cutting Speeds

One of the primary benefits of a fiber laser tube cutting machine is its ability to cut at much faster speeds compared to traditional cutting methods like saw cutting or plasma cutting. The fiber laser’s speed and efficiency enable manufacturers to meet tight production deadlines, improving throughput and reducing operational costs. Additionally, the technology’s ability to cut through thicker materials with ease makes it an ideal solution for various industries.

♦ Reduced Material Waste

Fiber lasers are highly efficient in terms of energy consumption and material usage. Traditional cutting methods often result in a considerable amount of scrap material, which drives up costs. However, with fiber lasers, the precision and accuracy reduce the amount of waste produced during the cutting process. This not only reduces material costs but also minimizes environmental impact, making fiber laser cutting a more sustainable option.

♦ Low Maintenance and Durability

Fiber laser machines generally require less maintenance compared to CO2 lasers or mechanical cutting methods. With fewer moving parts and a solid-state laser, these machines have a longer lifespan and experience less wear and tear. This durability reduces downtime and maintenance costs, providing manufacturers with a more cost-effective and reliable solution in the long term.

3. Key Applications of Fiber Laser Tube Cutting Machines

Fiber laser tube cutting machines are widely used across various industries. Their ability to cut a wide range of materials with precision makes them indispensable in many sectors.

♦ Automotive Industry

In the automotive sector, fiber laser tube cutting machines are used to produce a variety of components such as chassis parts, exhaust systems, and structural tubing. The ability to handle high-strength materials like stainless steel and aluminum makes fiber lasers an essential tool in the production of lightweight, durable automotive parts.

♦ Construction and Infrastructure

The construction and infrastructure sectors rely heavily on tube cutting for the fabrication of metal components such as beams, columns, and supports. Fiber laser technology allows for the efficient and accurate cutting of large metal tubes, ensuring that components meet the stringent requirements of building and infrastructure projects.

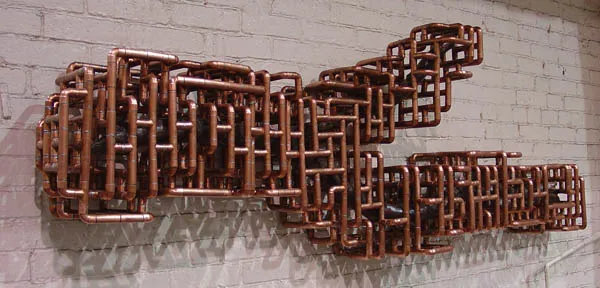

♦ Furniture and Design

In the furniture industry, designers use fiber laser tube cutting machines to create intricate designs in metal tubes. The flexibility of the technology allows for detailed patterns and shapes that would otherwise be difficult or impossible to achieve with other cutting methods.

♦ Aerospace Industry

The aerospace industry requires high-precision tube cutting for a variety of components, such as fuel lines, hydraulic systems, and structural parts. The fiber laser’s ability to cut with precision and handle a range of materials makes it ideal for these demanding applications.

4. How Fiber Laser Tube Cutting Machines Compare to Traditional Cutting Methods

When choosing the right cutting technology for tube fabrication, it’s important to compare fiber laser cutting with other traditional cutting methods.

♦ Speed and Efficiency

Fiber lasers significantly outperform traditional cutting methods such as saw cutting or plasma cutting in terms of speed. The continuous beam of light from the fiber laser provides a smooth, fast cutting process, whereas other methods often require multiple stages or slower cutting speeds. Additionally, fiber laser systems can work with both thin and thick metals, unlike some traditional machines that may struggle with thicker materials.

♦ Material Versatility

Fiber lasers excel at cutting a variety of materials, including metals that are highly reflective, such as brass and copper. Traditional cutting methods, particularly plasma cutting, may struggle with these materials, whereas fiber lasers maintain high cutting performance on a wide range of metals, including steel, aluminum, and titanium.

♦ Precision and Cleanliness

The clean, precise cuts offered by fiber lasers are far superior to those of mechanical cutting methods. While methods like plasma cutting can cause material distortion and require additional cleaning, the fiber laser’s focused beam creates smooth cuts that often require little to no post-processing. This results in higher-quality finished products and reduced rework.

5. Factors to Consider When Purchasing a Fiber Laser Tube Cutting Machine

When investing in a fiber laser tube cutting machine, there are several factors that should be considered to ensure the machine meets your specific needs.

♦ Power and Cutting Capacity

The laser’s power and cutting capacity determine how effectively it can handle various thicknesses and materials. Higher-power lasers are ideal for cutting thicker materials, while lower-power lasers are sufficient for thinner metals. Be sure to choose a machine with the appropriate power for your production requirements.

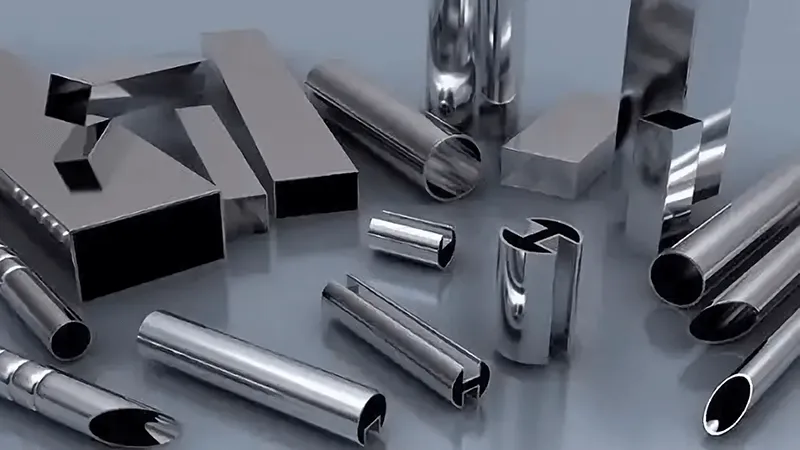

♦ Tube Size and Shape

Fiber laser tube cutting machines are available in various sizes and configurations to accommodate different tube diameters and shapes. Whether you’re working with small, intricate tubes or large, industrial pipes, choose a machine that can handle the tube sizes and shapes you work with most frequently.

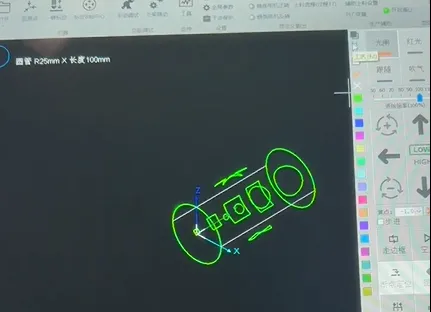

♦ Automation and Software Integration

Modern fiber laser tube cutting machines come equipped with advanced automation and software that can streamline the cutting process. These systems often include features like automatic material loading, cutting path optimization, and job scheduling, which can significantly improve production efficiency and reduce human error.

♦ Maintenance and Support

Before purchasing a fiber laser tube cutting machine, consider the level of maintenance required and the availability of customer support. Machines with fewer moving parts and easier maintenance processes are more cost-effective in the long run. Additionally, ensure that the manufacturer offers reliable customer service and technical support in case issues arise.

The fiber laser tube cutting machine is a key component of modern manufacturing, offering unmatched precision, speed, and material versatility. Its ability to deliver high-quality cuts with minimal waste makes it an essential tool for industries ranging from automotive to aerospace. With continued advancements in laser technology, the future of tube cutting looks promising, providing businesses with even more opportunities for innovation and growth.

Top Stories

-

4000W Laser Cutting Machine Guide | Essentials09 Dec 2025

4000W Laser Cutting Machine Guide | Essentials09 Dec 2025 -

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 kw laser cutting | Industrial precision guide28 Nov 2025

6 kw laser cutting | Industrial precision guide28 Nov 2025 -

Revolutionizing Industry with Steel Tube Laser Cutting Machine25 Nov 2025

Revolutionizing Industry with Steel Tube Laser Cutting Machine25 Nov 2025

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine