News

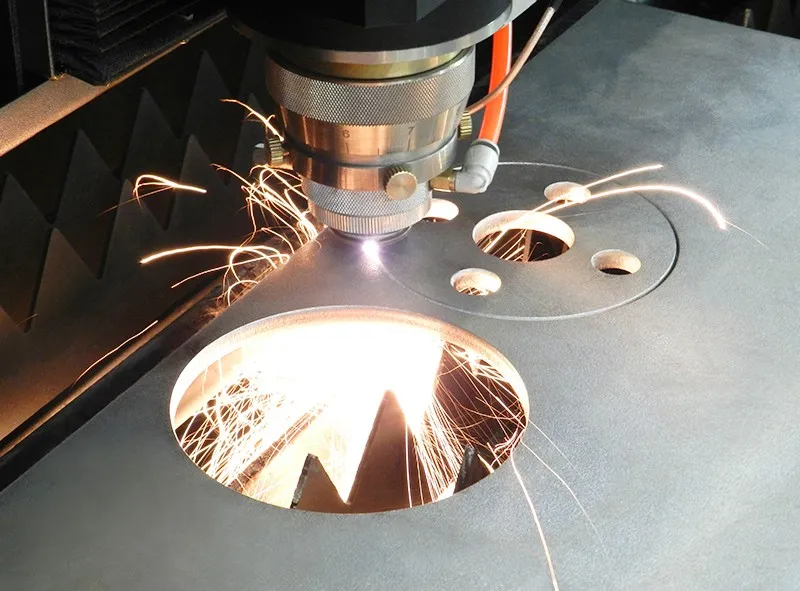

Laser Cutting Machine for Sheet Metal: A Game-Changer in Precision Manufacturing

Laser cutting machine for sheet metal technology has become an essential tool in modern manufacturing. Over the past few decades, this cutting-edge method has dramatically transformed how industries approach the fabrication and processing of sheet metal. The precision, speed, and versatility provided by laser cutting machines have made them indispensable in sectors such as automotive, aerospace, construction, and electronics.

As industries continue to push for higher efficiency and accuracy, laser cutting machine for sheet metal has proven itself to be a game-changer. From cutting intricate designs to handling complex materials, this technology offers numerous advantages that traditional cutting methods simply cannot match.

1.What Is a Laser Cutting Machine for Sheet Metal?

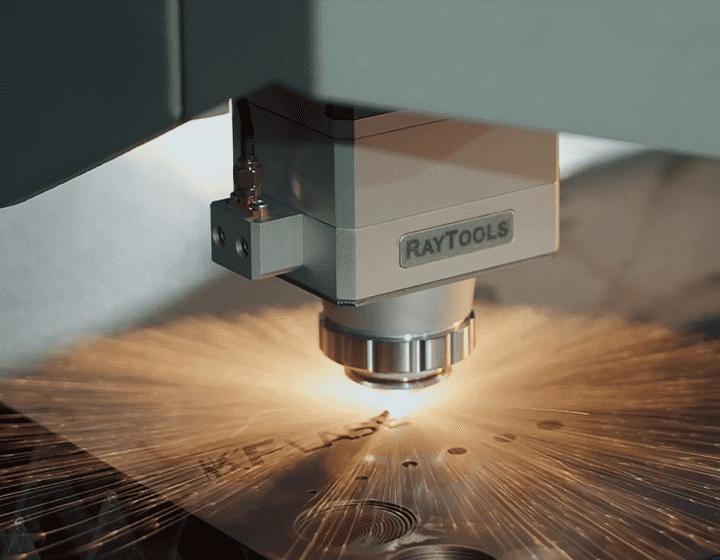

A laser cutting machine for sheet metal uses a focused laser beam to cut through metal sheets with extreme precision. The process works by directing a high-powered laser at the material, causing it to melt, burn, or vaporize. The result is a clean, precise cut without the need for physical contact, making it ideal for materials that are difficult to cut using traditional methods.

2.Advantages of Laser Cutting for Sheet Metal

Laser cutting for sheet metal offers several key advantages that make it the preferred choice for manufacturers seeking precision and efficiency.

◆Precision and Accuracy

One of the primary benefits of laser cutting machine for sheet metal is its ability to achieve incredibly precise cuts. The narrow laser beam ensures that even the most intricate designs can be cut with a high degree of accuracy. This eliminates the risk of human error and ensures a uniform product every time.

◆Speed and Efficiency

Laser cutting machines operate at high speeds, reducing production time and increasing overall efficiency. The automated nature of the process means that parts can be produced with minimal downtime, allowing manufacturers to meet tight deadlines without compromising on quality.

◆Minimal Material Waste

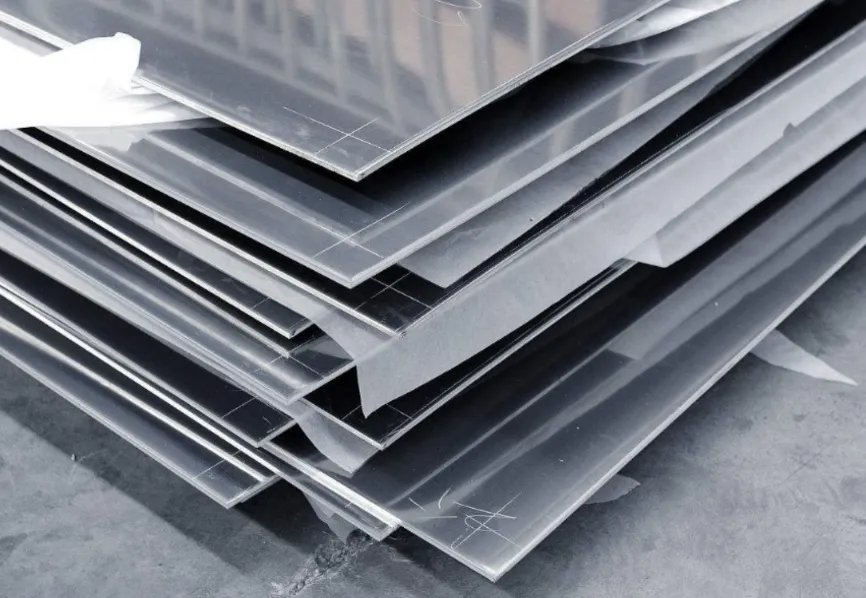

Laser cutting for sheet metal is a highly efficient process, as the laser beam can cut with minimal waste. The narrow width of the cut (also known as the kerf) ensures that more of the material is used, which is particularly important in industries where raw material costs are high.

◆Versatility in Materials

Laser cutting machine for sheet metal is capable of working with a wide range of materials, including metals of varying thicknesses. This versatility makes it an ideal choice for industries that require precise cuts in different types of metals, from stainless steel to copper.

◆Clean Edges with Minimal Finishing

Unlike traditional cutting methods, which often leave rough edges that require additional finishing, laser cutting produces smooth, clean edges. This reduces the need for post-processing, saving time and money while maintaining the integrity of the material.

3.Applications of Laser Cutting Machines for Sheet Metal

Laser cutting machines for sheet metal are used across a variety of industries, providing solutions for both simple and complex manufacturing processes.

Automotive Industry

In the automotive industry, laser cutting machine for sheet metal is used to fabricate components like chassis, exhaust systems, and body panels. The precision of the cuts ensures that each part fits perfectly, reducing the need for additional adjustments during assembly. The high speed of the process also allows manufacturers to meet the high-volume demands of the automotive sector.

Aerospace Industry

The aerospace industry demands the highest level of precision, and laser cutting machine for sheet metal delivers exactly that. Components used in aircraft must meet strict tolerance standards, and laser cutting offers the accuracy required to ensure the reliability and safety of each part. Whether it’s cutting structural components or intricate engine parts, laser cutting plays a critical role in aerospace manufacturing.

Construction and Architecture

In construction, laser cutting machine for sheet metal is used for cutting steel components for buildings, bridges, and other infrastructure projects. The ability to produce precise cuts with minimal material waste is particularly beneficial in construction, where time and cost are always key considerations.

Laser cutting is also used in architectural design, enabling the creation of unique and complex metalwork for facades, decorative features, and interior elements. The versatility of the technology allows architects to bring their most ambitious designs to life with ease.

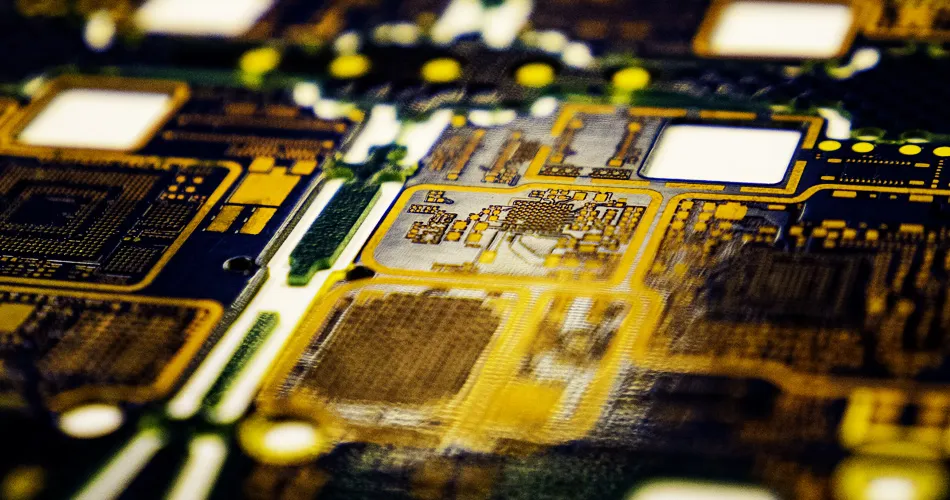

Electronics and Electrical Equipment

The electronics industry relies on laser cutting machine for sheet metal for the precise cutting of metal enclosures, circuit board housings, and other components. The clean, accurate cuts produced by laser cutting are essential for the small-scale, intricate parts used in electronic devices.

4.How to Choose the Right Laser Cutting Machine for Sheet Metal

When selecting a laser cutting machine for sheet metal, several factors should be taken into consideration to ensure that the machine meets the needs of your specific manufacturing process.

Material Type and Thickness

Different laser cutting machines are designed to handle specific materials and thicknesses. Consider the types of metals you will be cutting and ensure that the machine is capable of handling them. For example, fiber laser cutting machines are ideal for cutting thinner materials, while CO2 lasers are better suited for thicker metals.

Cutting Speed

Depending on the production volume and turnaround time, the speed of the laser cutting machine is an important consideration. High-speed machines are more suitable for mass production, while slower machines may be appropriate for small-batch runs or intricate designs.

Precision Requirements

If your project requires highly detailed cuts, look for a machine that offers high precision and accuracy. Some machines are capable of cutting with tolerances as tight as 0.1mm, which is crucial for industries like aerospace and electronics.

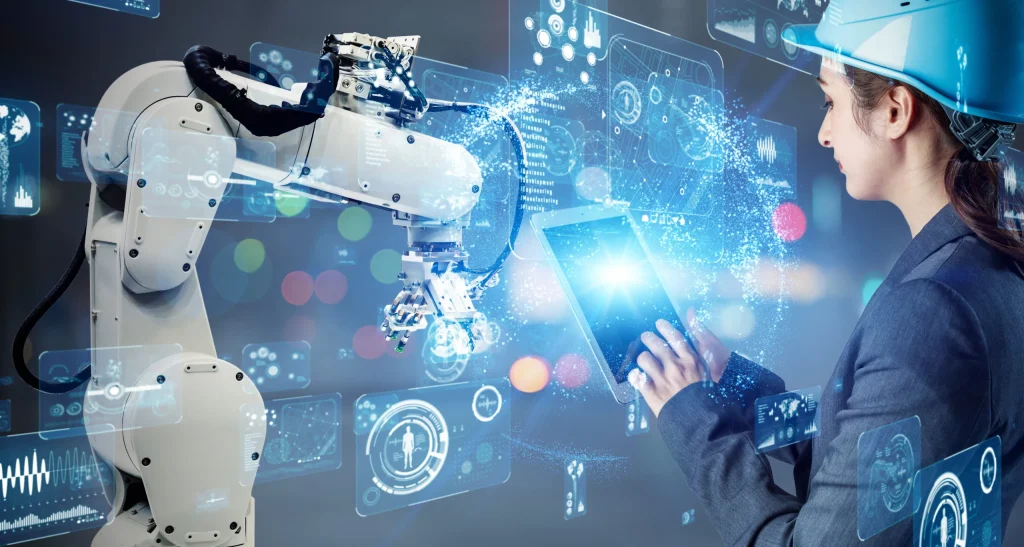

Automation and Software

Many modern laser cutting machines come equipped with advanced software that allows for automation and optimization of the cutting process. Automated systems can improve efficiency and reduce the need for manual intervention, making the production process smoother and faster.

Cost and Maintenance

Consider both the initial investment and long-term maintenance costs when purchasing a laser cutting machine for sheet metal. While laser cutting machines are an investment, the cost savings in terms of time and material waste can offset the initial expense in the long run.

5.Future Trends in Laser Cutting for Sheet Metal

The laser cutting industry continues to evolve, with new technologies and innovations pushing the boundaries of what’s possible in metal fabrication. Some key trends to watch include:

Integration with AI and Automation

The integration of artificial intelligence (AI) and automation is making laser cutting machines even more efficient. These systems can optimize cutting paths, reduce waste, and improve the overall speed of production.

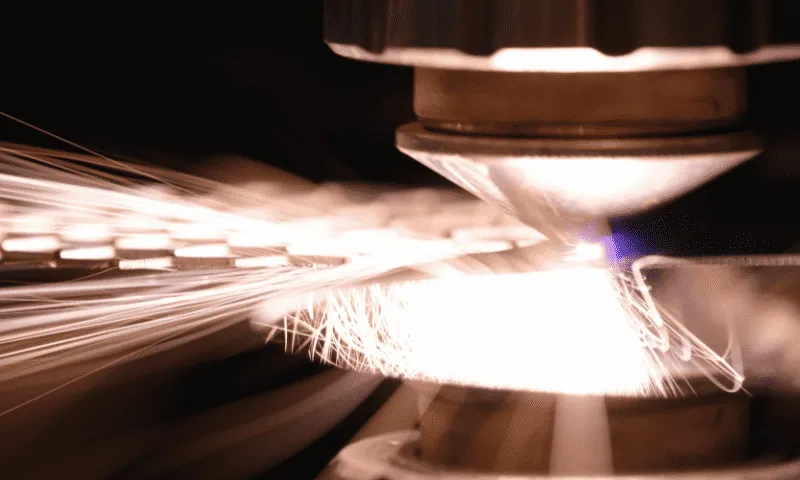

Fiber Laser Technology

Fiber lasers are becoming increasingly popular for sheet metal cutting due to their ability to provide faster cutting speeds and better energy efficiency compared to traditional CO2 lasers.

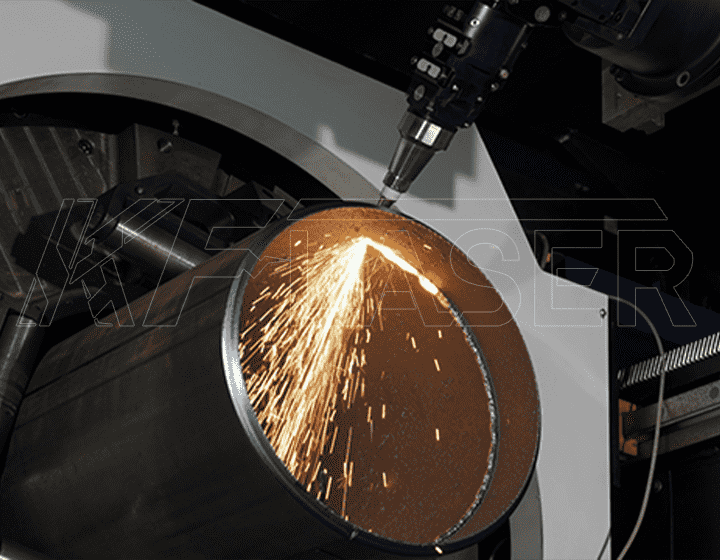

3D Laser Cutting

As manufacturing needs become more complex, 3D laser cutting technology is gaining traction. This method allows for the cutting of metal sheets into complex 3D shapes, opening up new possibilities for product design.

Sustainability Initiatives

As industries continue to focus on sustainability, laser cutting’s minimal material waste and energy-efficient processes are becoming even more appealing. Manufacturers are increasingly turning to laser cutting as a more environmentally friendly option compared to traditional cutting methods.

The role of laser cutting machine for sheet metal in modern manufacturing cannot be overstated. It continues to push the boundaries of precision, speed, and efficiency, enabling industries to meet the growing demand for high-quality products. Whether for large-scale production or custom fabrication, laser cutting is an essential tool for manufacturers looking to stay competitive in a rapidly evolving market.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine