News

Laser Cutting Machine Metal: Revolutionizing the Metal Fabrication Industry

In the ever-evolving world of manufacturing, laser cutting machine metal technology has emerged as a transformative force. Gone are the days of relying on traditional methods that were slower, less precise, and often more labor-intensive. Today, laser cutting has become the gold standard in metal fabrication due to its speed, accuracy, and efficiency. Whether you’re looking to create intricate designs, optimize your production processes, or reduce waste, laser cutting offers the solution.

Laser cutting is not just about precision; it’s about pushing the boundaries of what’s possible in metalworking. This technology has completely reshaped industries, from automotive manufacturing to aerospace, and is now at the heart of innovation in industries that rely on precision metal parts.

1. What is a Laser Cutting Machine for Metal?

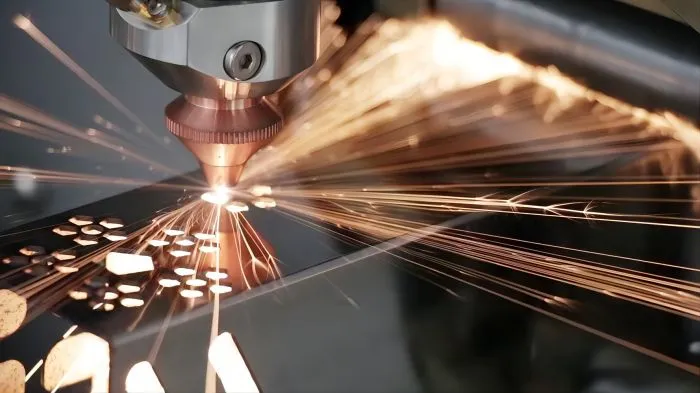

At its core, a laser cutting machine for metal uses a high-powered laser beam to melt, burn, or vaporize the material along a predefined path, achieving highly accurate cuts. Unlike mechanical cutting methods, laser cutting doesn’t involve physical contact with the material, which minimizes wear and tear on the machine and improves overall precision.

Laser cutting machines for metal are controlled by computer software that guides the laser beam, ensuring the cuts are made exactly as planned. These machines are capable of cutting through a variety of metals, including stainless steel, aluminum, copper, and carbon steel, with exceptional speed and precision.

2. The Advantages of Laser Cutting for Metal

Precision and Accuracy

Laser cutting machines for metal are known for their remarkable precision. Unlike traditional mechanical cutting methods, which often produce jagged or uneven edges, laser cutting creates smooth, clean edges. The precision of laser cutting is perfect for producing intricate and complex shapes, even with small tolerances. This accuracy is crucial in industries such as aerospace and automotive manufacturing, where part failure due to inaccurate cuts is unacceptable.

Speed and Efficiency

The speed at which laser cutting machines work is another significant advantage. With the ability to make precise cuts rapidly, laser cutting machines can handle high-volume production runs without compromising on quality. The faster processing times lead to more efficient workflows, enabling manufacturers to meet tight deadlines and reduce overall production costs.

Reduced Material Waste

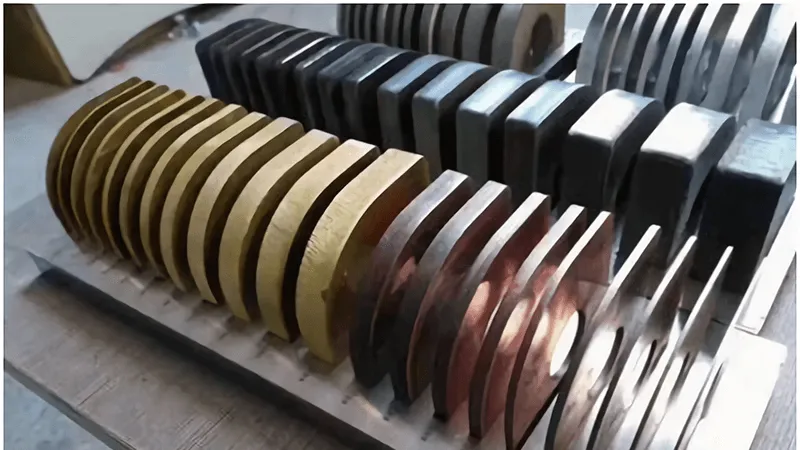

One of the key benefits of laser cutting is its ability to reduce material waste. Laser cutting uses a narrow beam to make cuts, which means that less material is discarded compared to other cutting methods. This is particularly important in industries that work with expensive metals, as the cost savings from reduced waste can be significant.

Versatility in Cutting Shapes

Laser cutting is incredibly versatile. It can be used to cut simple shapes or complex designs, making it ideal for a wide range of applications. The software that controls laser cutting machines can easily adjust to different designs and materials, making it easy for manufacturers to modify their production processes without having to invest in new equipment or tools.

3. Types of Laser Cutting Technologies

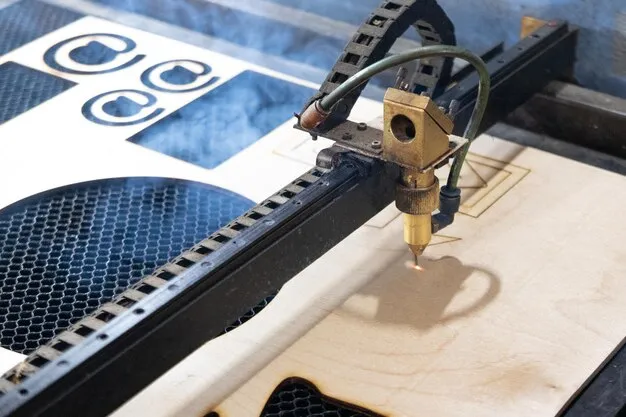

CO2 Lasers

CO2 lasers are one of the most commonly used laser cutting technologies. These lasers are highly effective for cutting thicker metals and are especially suitable for non-metallic materials. CO2 lasers are known for their ability to cut with great precision and are often used in industries such as automotive and heavy manufacturing.

Fiber Lasers

Fiber lasers are increasingly popular due to their efficiency, speed, and ability to cut a wide range of metals with high precision. Fiber lasers offer faster cutting speeds and lower energy consumption compared to CO2 lasers. These lasers are ideal for cutting metals like stainless steel, aluminum, and brass, and are commonly used in industries such as electronics, aerospace, and metal fabrication.

YAG Lasers

YAG lasers, or yttrium-aluminum-garnet lasers, are known for their ability to focus a small, high-powered beam to make precise cuts in a variety of metals. YAG lasers are typically used for cutting thinner metals and are particularly valuable in applications requiring small hole drilling or micro-cutting.

4. Applications of Laser Cutting in Metal Fabrication

Automotive Industry

The automotive industry benefits greatly from laser cutting technology. Laser cutting machines are used to create a wide range of automotive parts, from exhaust systems to frame components. The precision of laser cutting allows manufacturers to produce parts that meet stringent quality standards, reducing the risk of defects and ensuring the safety and performance of the vehicles.

Aerospace and Aviation

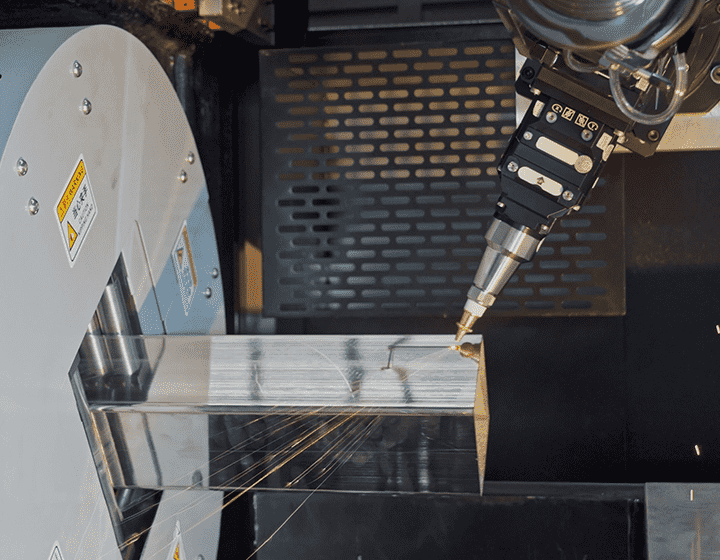

In aerospace and aviation, where safety and performance are critical, laser cutting is essential. Laser cutting machines are used to produce high-precision components such as engine parts, brackets, and fuselage components. The ability to cut metals to the exact specifications required for aerospace applications ensures the durability and reliability of these critical parts.

Metalworking and Manufacturing

Laser cutting has become a cornerstone of the metalworking and manufacturing industries. From sheet metal fabrication to the production of custom metal parts, laser cutting machines offer an efficient, precise solution for high-volume production. These machines enable manufacturers to meet complex design requirements while reducing material waste and improving overall efficiency.

Medical Device Manufacturing

Laser cutting machines for metal are used extensively in the medical device industry. These machines allow for the creation of intricate and highly precise parts used in medical devices, such as surgical instruments, implants, and diagnostic equipment. The high precision of laser cutting ensures that these critical parts meet the strict regulatory requirements of the healthcare industry.

5. How to Choose the Right Laser Cutting Machine for Metal

When selecting a laser cutting machine for metal, several factors should be considered:

Material Compatibility

Consider the types of metals you will be cutting. Some laser cutting machines are better suited for certain materials, such as fiber lasers for high-speed cutting of stainless steel or aluminum. Make sure the machine you choose can handle the materials your business requires

Cutting Thickness and Speed

The thickness of the material you’re cutting is another important factor. Thicker metals may require a more powerful laser or a different type of laser cutting technology. Additionally, speed is an important consideration, especially for high-volume production environments.

Software and Ease of Use

The software that controls the laser cutting machine is crucial for its performance. Choose a machine with user-friendly software that can easily integrate with your existing design files and workflows. The right software will help optimize your cutting process, reduce waste, and improve efficiency.

Laser cutting machines for metal have revolutionized the fabrication industry by providing manufacturers with faster, more precise, and more efficient cutting capabilities. From reducing material waste to increasing production speeds, these machines are essential tools for businesses that rely on metal parts. Whether you’re working in automotive, aerospace, or metal manufacturing, investing in laser cutting technology will help streamline your operations, improve product quality, and give your business a competitive edge in today’s fast-paced market.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine