News

Tube Laser Cutting Machines: Revolutionizing Metal Pipe Fabrication

The introduction of tube laser cutting machines has revolutionized the way industries handle metal pipe and tube cutting. With the increasing demand for high-precision, cost-effective solutions in sectors like construction, automotive, aerospace, and manufacturing, tube laser cutting machines are becoming indispensable. These machines provide unparalleled precision, speed, and versatility, making them a game-changer in the modern world of metal fabrication.

But what exactly makes tube laser cutting machines so special? Let’s take a deep dive into the technology, benefits, applications, and how it’s transforming industries one cut at a time.

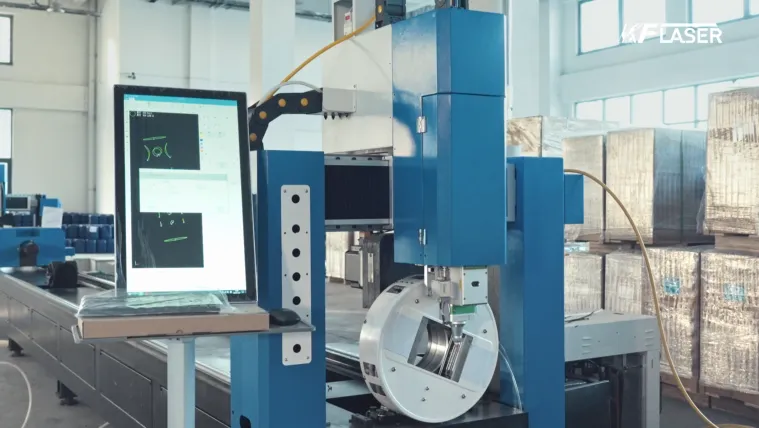

1. What Are Tube Laser Cutting Machines?

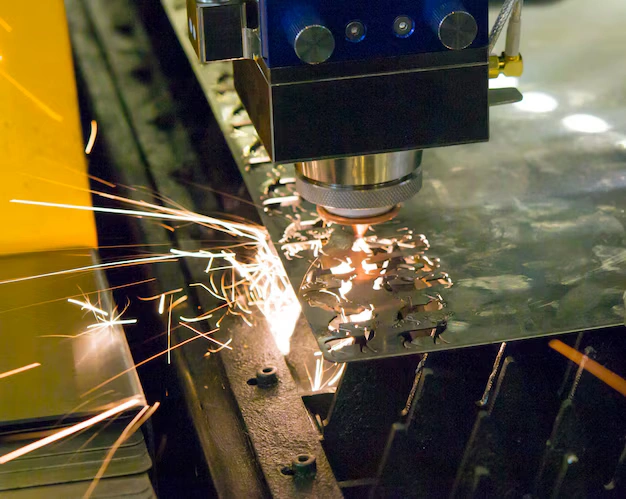

Tube laser cutting machines are a type of CNC (Computer Numerical Control) machine used to cut metal pipes and tubes. They utilize a focused laser beam to precisely cut through materials like steel, stainless steel, aluminum, and other metals. This process involves directing a high-powered laser onto the material, causing it to melt, vaporize, or blow away the material in a precise manner. The result? Clean, accurate cuts that minimize waste and require minimal finishing.

These machines come with advanced software that controls the movement of the laser head along multiple axes, ensuring that even the most intricate and complex designs can be cut with ease. Unlike traditional cutting methods, such as saws or plasma cutters, tube laser cutting machines provide superior precision and speed, which is crucial for industries demanding high standards of accuracy.

2. How Do Tube Laser Cutting Machines Work?

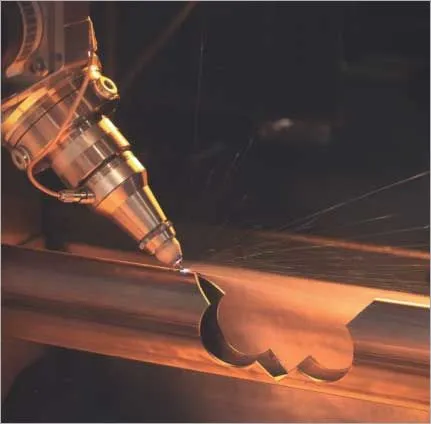

Laser Technology at Its Core

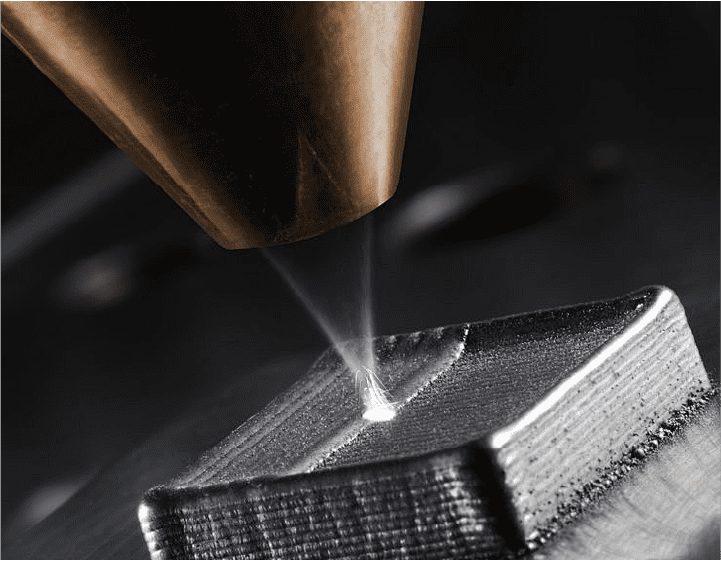

The cutting process of tube laser machines begins with the generation of a laser beam. This beam is focused through optics onto the metal surface. The laser’s concentrated heat causes the material to melt or vaporize along the desired cut path. Since the laser does not physically touch the material, it minimizes wear and tear, offering consistent and high-quality cuts over time.

The laser’s intensity, speed, and movement are precisely controlled by the machine’s CNC system, allowing it to follow detailed instructions programmed by the operator. This ensures that each tube cut is not only fast but also extremely accurate.

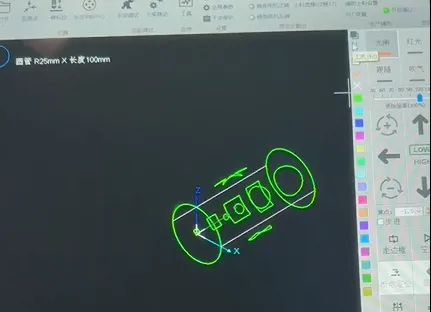

CNC Automation: Ensuring Precision

At the heart of tube laser cutting machines lies CNC automation. With CNC, manufacturers can input complex geometric shapes, and the machine will replicate them with extreme accuracy, automatically adjusting its path in real-time. This level of automation significantly reduces human error, minimizes labor costs, and increases production speed.

The CNC system is key for repeatability and quality control, enabling operators to consistently produce high-precision cuts across a large volume of metal parts.

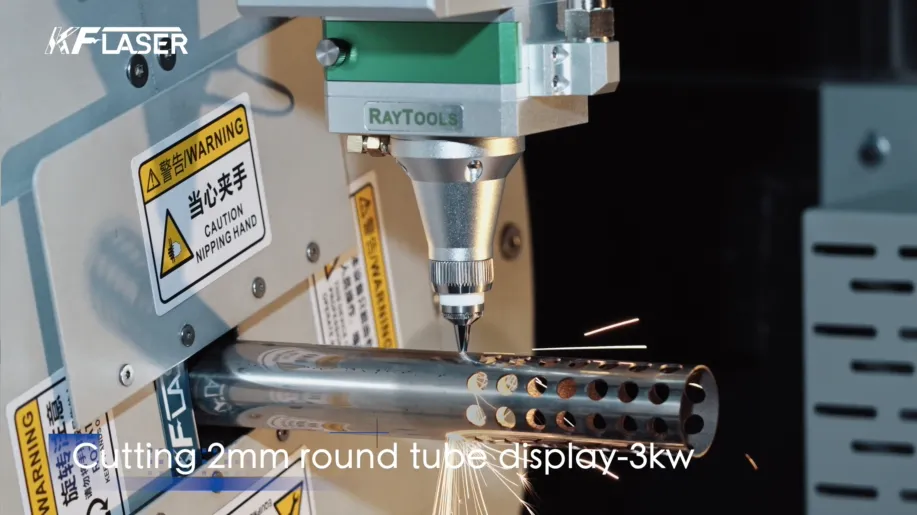

Cutting Capabilities: Versatility Beyond Simple Cuts

Tube laser cutting machines are capable of much more than just straight cuts. They can handle a wide variety of cutting operations, including:

Circular cuts for creating holes in the middle of pipes

Complex patterns such as slots, angles, and curves

Angle cutting to accommodate bevels and other intricate geometries

3D cutting for tubes that require a multi-dimensional approach

These capabilities make tube laser cutting machines a versatile solution for creating a wide range of products across multiple industries.

3. Key Advantages of Tube Laser Cutting Machines

Precision and Accuracy

Tube laser cutting machines offer exceptional precision, which is critical in industries that require the utmost accuracy. Whether cutting pipes for structural components, exhaust systems, or fluid transport lines, the laser’s ability to create cuts with tight tolerances ensures that each part fits perfectly without the need for additional processing or rework.

Faster Production Times

One of the most significant benefits of tube laser cutting machines is their speed. Unlike traditional methods, which can be slow and require multiple steps, laser cutting allows for fast, efficient cuts with minimal setup time. This increased speed translates into higher throughput and greater overall productivity, which is crucial for businesses competing in fast-paced markets.

Reduced Material Waste

Laser cutting is known for its precision and narrow kerf, which means less material is wasted during the cutting process. This is especially beneficial in industries where raw materials are expensive. With less scrap material to dispose of, companies can maximize their use of materials, reducing overall costs and contributing to more sustainable manufacturing practices.

Improved Design Flexibility

Another significant advantage of tube laser cutting machines is the flexibility they provide in terms of design. With laser cutting, designers can experiment with more complex geometries and intricate designs without worrying about the limitations of traditional cutting methods. Custom cuts, angles, and shapes can be programmed into the CNC system, allowing manufacturers to meet the unique requirements of their clients without compromising on quality or efficiency.

4. Applications of Tube Laser Cutting Machines

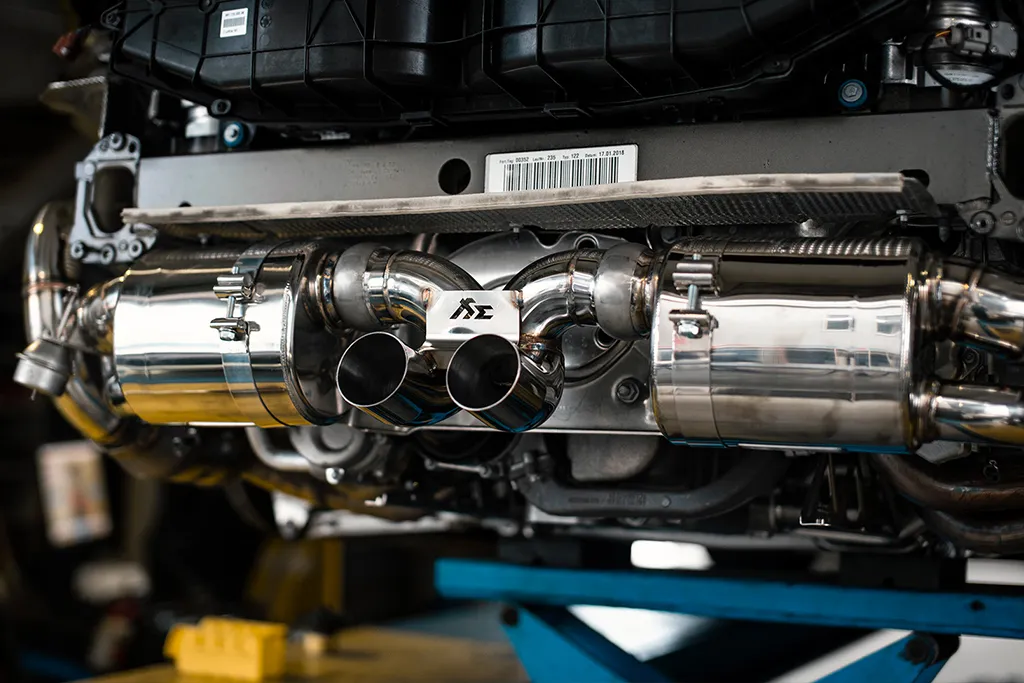

Automotive Industry

In the automotive sector, tube laser cutting machines play a critical role in manufacturing vehicle components, including exhaust pipes, structural frames, and suspension parts. Their ability to provide precision cuts ensures that each part fits perfectly, contributing to the overall performance and safety of the vehicle.

Aerospace and Aviation

The aerospace industry demands the highest standards of quality and precision. Tube laser cutting machines are widely used to cut lightweight, high-strength tubes and pipes for aircraft and spacecraft components. Whether cutting parts for engines, fuel lines, or hydraulic systems, the precision of laser cutting ensures the safety and reliability of aerospace structures.

Construction and Structural Applications

In construction, the need for strong, durable materials is paramount. Tube laser cutting machines are used to cut pipes for handrails, support beams, and other structural elements. Their ability to cut with precision ensures that these critical parts meet the strict safety and regulatory standards required in the construction industry.

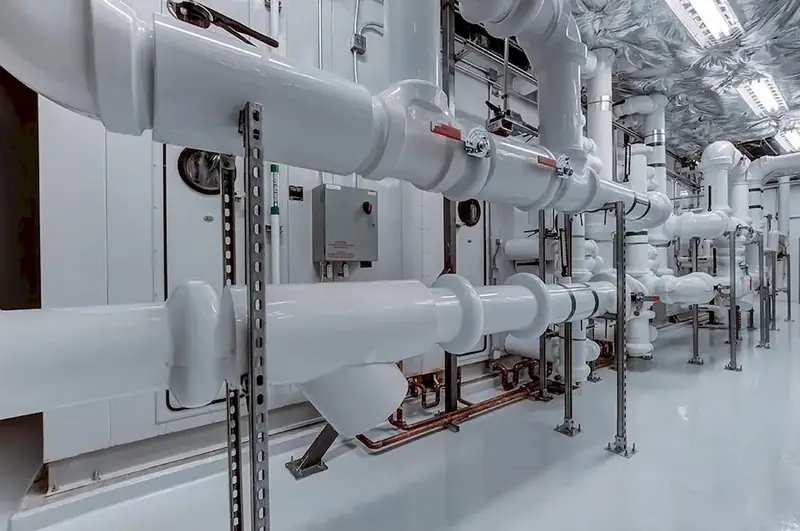

Energy Sector

The energy industry, particularly in oil and gas, relies heavily on tube laser cutting machines to fabricate pipes for drilling, transportation, and power generation. The ability to cut through thick materials while maintaining precision makes these machines ideal for creating the robust and reliable piping systems necessary in energy production.

5. How to Choose the Right Tube Laser Cutting Machine

Consider Cutting Size and Thickness

When selecting a tube laser cutting machine, it’s essential to consider the size and thickness of the pipes you plan to cut. Some machines are designed to handle larger pipes, while others are better suited for smaller, more intricate cuts. Choosing the right machine ensures that your production process remains efficient and cost-effective.

Evaluate Material Compatibility

Different materials require different types of laser cutting machines. Ensure that the machine you choose is compatible with the materials you intend to cut, whether they are mild steel, stainless steel, aluminum, or other metals.

5.3 Machine Speed and Output

The speed of the machine will significantly affect the throughput of your operations. If you need to produce high volumes of parts quickly, choose a tube laser cutting machine with high-speed cutting capabilities. Look for machines with advanced features like automatic tube loading and unloading to further enhance productivity.

Software and Control System

The software used to control tube laser cutting machines is crucial for ensuring precise cuts. Make sure the machine’s software is user-friendly and supports the types of designs and shapes you plan to create. Advanced software options offer features like real-time cutting adjustments and easy integration with CAD designs.

In conclusion, tube laser cutting machines have become a transformative tool in modern manufacturing, offering a level of precision, speed, and efficiency that traditional cutting methods simply cannot match. From automotive to aerospace, construction to energy, these machines are improving the manufacturing process across various industries. Whether you’re a small business or a large enterprise, investing in a tube laser cutting machine could significantly enhance your production capabilities and provide a competitive edge in the market.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine