News

Laser Cut Stainless Steel: A New Era in Precision Metalworking

In today’s world of high-precision manufacturing, laser cut stainless steel is at the forefront of innovation. It’s the technology that’s reshaping industries from aerospace to automotive, providing manufacturers with a tool that offers unmatched precision, speed, and versatility. With its ability to cut through stainless steel with extreme accuracy and minimal waste, laser cutting is changing the way we think about metal fabrication.

Gone are the days of traditional cutting methods, which often left behind burrs, rough edges, and slower processing times. Laser cutting for stainless steel, with its fine beam, can cut through thick sheets of metal effortlessly, while also allowing for intricate patterns and designs that would have been impossible with traditional methods.

Ⅰ.What Is Laser Cutting of Stainless Steel?

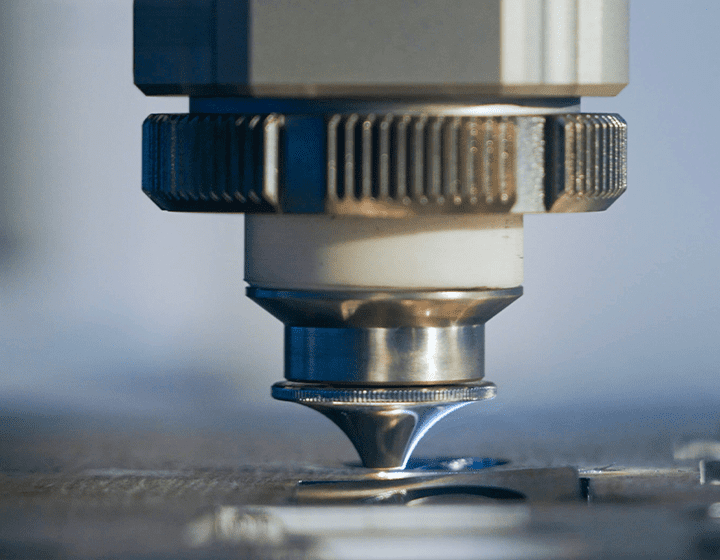

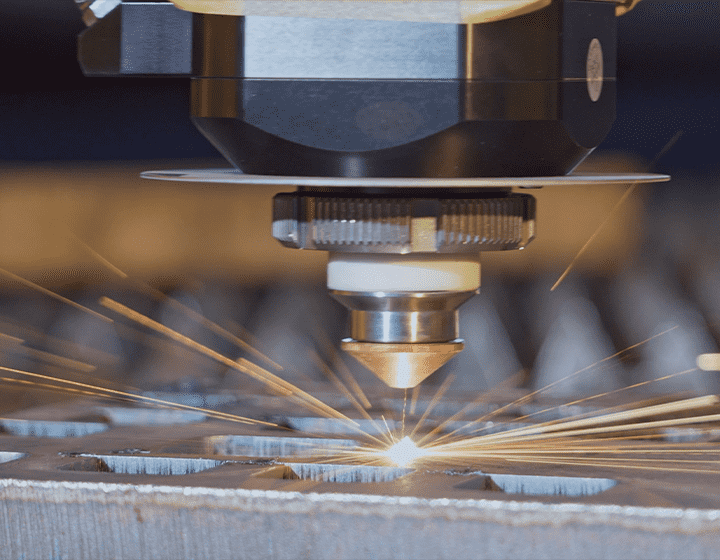

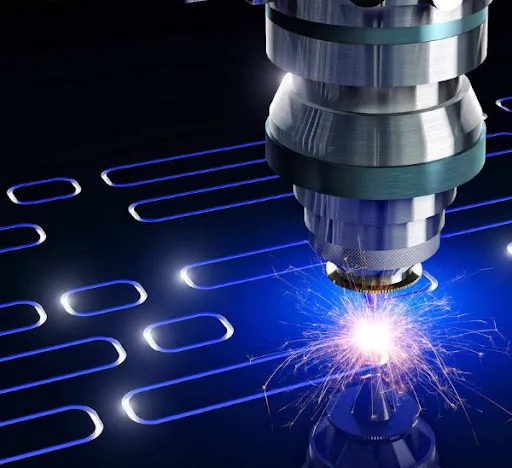

Laser cutting uses a focused laser beam to heat and melt stainless steel along a designated path. Unlike traditional cutting methods, such as sawing or shearing, laser cutting is a non-contact method. This means that the cutting head never touches the material, reducing wear and tear on the machine and leading to higher precision cuts.

The process of laser cutting involves several key components:

◆Laser beam generation: A high-powered laser beam is created in a laser resonator and is directed onto the workpiece.

♦Focusing: The beam is focused on a fine point, allowing for highly detailed and clean cuts.

♦Movement: The laser cutting head is moved according to a computer-aided design (CAD) file, which ensures the precision of the cut.

♦Melting or vaporizing: The laser melts or vaporizes the stainless steel, with the excess material being blown away by a stream of gas.

Ⅱ. The Advantages of Laser Cutting Stainless Steel

Precision and Accuracy

Laser cutting technology is renowned for its precision. With lasers, manufacturers can cut stainless steel to incredibly tight tolerances, ensuring that each part is consistent and high-quality. This level of accuracy is crucial for industries where parts must fit perfectly or meet strict specifications, such as in aerospace or medical device manufacturing.

Speed and Efficiency

Laser cutting machines work at high speeds, which increases production rates and reduces overall manufacturing costs. The quick cutting process allows manufacturers to maintain fast turnaround times, which is especially important in industries where time-to-market is critical. Furthermore, the high-speed process doesn’t sacrifice the quality or precision of the cuts, allowing for an efficient workflow.

Minimal Waste

One of the most significant advantages of laser cutting stainless steel is the minimal material waste produced during the process. The focused laser beam makes extremely narrow cuts, leaving very little scrap material behind. This reduces the cost of raw materials and improves sustainability by minimizing waste.

Versatility

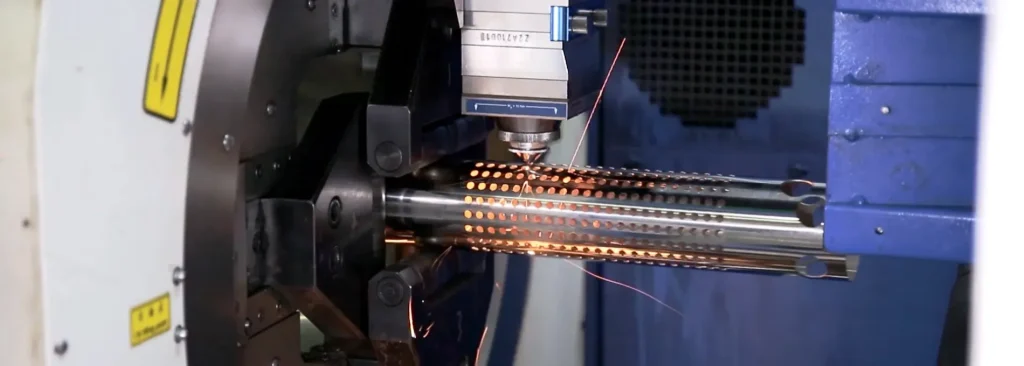

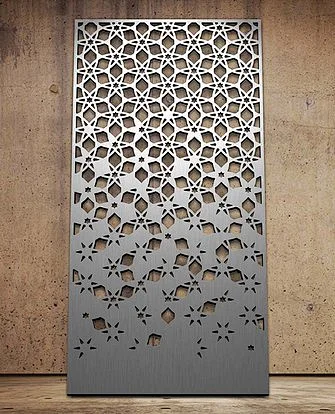

Laser cutting technology is incredibly versatile and can cut a variety of shapes and thicknesses with ease. Stainless steel can be cut into complex designs, intricate patterns, and fine details with ease, making it suitable for a wide range of industries. Whether you’re cutting sheets of stainless steel, tubes, or custom pieces, laser cutting provides a flexible solution that meets diverse manufacturing needs.

Ⅲ. How Does Laser Cutting Stainless Steel Compare to Other Methods?

Laser cutting offers several advantages over traditional methods such as plasma cutting, waterjet cutting, and mechanical cutting:

♦Plasma Cutting: While plasma cutting is faster, it produces rougher edges and is less accurate than laser cutting. Additionally, plasma cutting can create more heat-affected zones (HAZ), which can weaken the stainless steel around the cut.

♦Waterjet Cutting: Waterjet cutting uses a high-pressure stream of water mixed with abrasives to cut materials. While it produces smooth edges, it is generally slower than laser cutting and can be less precise, especially when cutting thicker materials.

♦Mechanical Cutting: Traditional methods such as shearing or sawing involve physical contact with the material. This leads to more wear and tear on the equipment and the potential for rough edges. Laser cutting, in contrast, is faster, more precise, and requires less maintenance on the cutting head.

Laser cutting is particularly effective for cutting stainless steel because it ensures clean, precise edges without the need for further finishing work.

Ⅳ. Applications of Laser Cutting Stainless Steel

Aerospace Industry

In the aerospace industry, precision is key. Laser cutting stainless steel is used to create highly detailed and accurate components, such as engine parts, airframes, and brackets. These parts must meet rigorous safety and quality standards, and laser cutting provides the necessary precision and strength.

Automotive Manufacturing

The automotive industry benefits greatly from the accuracy and speed of laser cutting technology. Stainless steel components such as exhaust systems, chassis parts, and body panels are often made using laser cutting machines. The precision offered by lasers ensures that these parts fit together perfectly, leading to better overall performance and durability.

Architecture and Construction

Laser cutting stainless steel has made a huge impact in architecture and construction. Architects and builders use laser cutting to create decorative elements, structural components, and even entire facades for buildings. The ability to cut intricate designs into stainless steel has allowed for more creativity and innovation in building design.

Medical Devices and Instruments

Laser cutting stainless steel plays a vital role in the medical industry. Stainless steel is commonly used to make surgical instruments, medical devices, and implants. The high precision and ability to cut thin and complex parts make laser cutting the ideal method for manufacturing medical equipment that needs to meet stringent health and safety standards.

Ⅵ. The Future of Laser Cutting Stainless Steel

As technology continues to advance, so too does the capability of laser cutting machines. The latest innovations in laser cutting technology are improving efficiency, reducing costs, and allowing manufacturers to cut even more challenging materials with greater precision. Fiber lasers, in particular, are becoming more common due to their ability to cut faster and more efficiently, especially with materials like stainless steel.

With the ongoing development of laser technology, the future of laser cut stainless steel looks even more promising. The ability to cut stainless steel with virtually no heat distortion, high precision, and minimal waste is paving the way for new applications and more advanced manufacturing processes.

In conclusion, laser cut stainless steel has revolutionized industries that rely on precision metalworking. From automotive to aerospace and medical devices, this cutting-edge technology offers a reliable, efficient, and cost-effective solution for manufacturers. By choosing laser cutting, businesses can ensure high-quality, precise cuts with minimal waste, driving both innovation and sustainability. As the technology continues to evolve, laser cutting will remain a vital tool for industries across the globe.

Top Stories

-

4000W Laser Cutting Machine Guide | Essentials09 Dec 2025

4000W Laser Cutting Machine Guide | Essentials09 Dec 2025 -

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 kw laser cutting | Industrial precision guide28 Nov 2025

6 kw laser cutting | Industrial precision guide28 Nov 2025 -

Revolutionizing Industry with Steel Tube Laser Cutting Machine25 Nov 2025

Revolutionizing Industry with Steel Tube Laser Cutting Machine25 Nov 2025

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine