News

Tube Laser Cutting Machine: Revolutionizing Precision in Metal Fabrication

In the ever-evolving world of manufacturing, tube laser cutting machines have become game-changers, offering unmatched precision and efficiency in metalworking. Whether it’s for automotive parts, medical devices, or structural components, tube laser cutting offers superior results that traditional cutting methods simply cannot match. The power of this technology lies in its ability to cut through various metals with incredible accuracy, offering both speed and cost-effectiveness.

Gone are the days when metal cutting required numerous steps and produced excess waste. Today, tube laser cutting has transformed metal fabrication into a process that’s faster, more efficient, and capable of delivering higher-quality results.

Ⅰ.What Is a Tube Laser Cutting Machine?

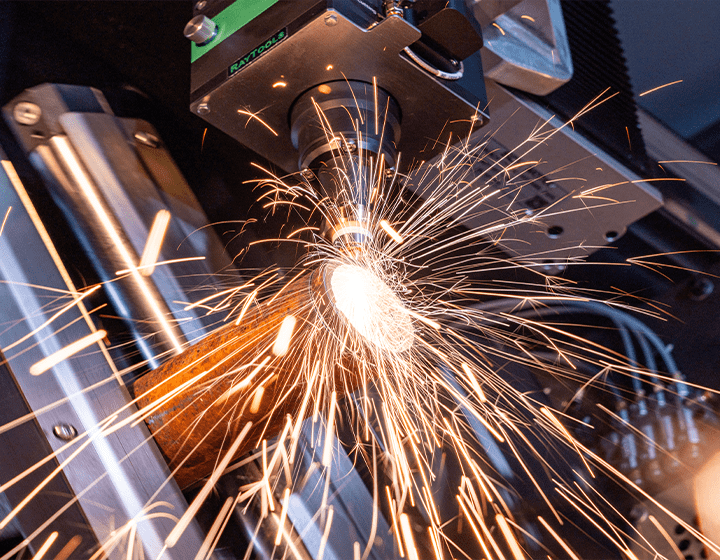

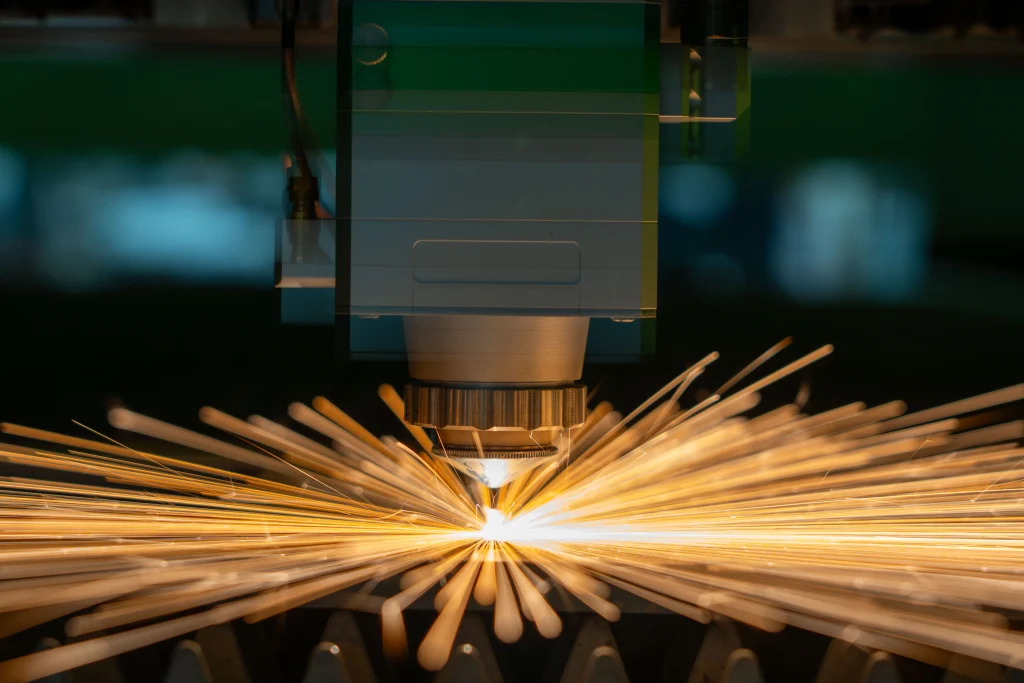

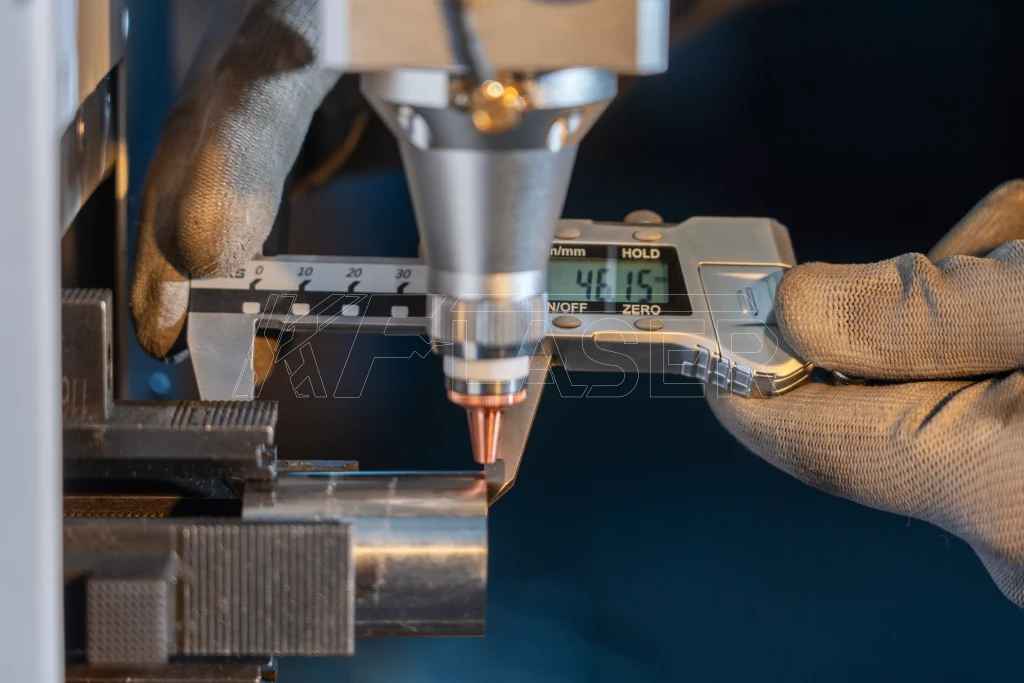

A tube laser cutting machine is an advanced tool that uses a high-powered laser beam to precisely cut through tubular materials like steel, aluminum, and stainless steel. This method uses a focused laser beam to vaporize or melt the material along a pre-determined path. Unlike traditional cutting tools, laser cutting does not require physical contact with the material, resulting in a cleaner cut and fewer chances of material distortion.

The cutting process is typically controlled by a computer numerical control (CNC) system, which allows for intricate designs and shapes to be produced quickly and with high accuracy. Tube laser cutting machines are often used in industries requiring high precision and complex geometries, such as aerospace, automotive, and manufacturing.

In the ever-evolving world of manufacturing, tube laser cutting machines have become game-changers, offering unmatched precision and efficiency in metalworking. Whether it’s for automotive parts, medical devices, or structural components, tube laser cutting offers superior results that traditional cutting methods simply cannot match. The power of this technology lies in its ability to cut through various metals with incredible accuracy, offering both speed and cost-effectiveness.

Gone are the days when metal cutting required numerous steps and produced excess waste. Today, tube laser cutting has transformed metal fabrication into a process that’s faster, more efficient, and capable of delivering higher-quality results.

Tube Laser Cutting Machine

Welcome to our website.

KF LASERⅡ.Why Choose a Tube Laser Cutting Machine?

Unmatched Precision and Accuracy

Tube laser cutting machines excel in precision. The laser beam, which is highly focused, ensures that cuts are sharp and accurate. This allows for tighter tolerances than other traditional methods like sawing or punching, making laser cutting ideal for industries where precision is crucial. Whether it’s intricate perforations, tight bends, or complex geometries, tube laser cutting can handle it all with ease.

Speed and Efficiency

The ability of tube laser cutting machines to perform quick and efficient cuts allows for shorter production times. The system operates faster than conventional methods, resulting in increased throughput and reduced production time. This makes it an excellent choice for manufacturers that need to produce high volumes of parts quickly.

In addition, tube laser cutting machines are capable of working with multiple materials and thicknesses, making them highly versatile. Unlike other machines that might require different settings or tools for different types of metals, tube laser cutters adjust automatically, saving time and reducing setup costs.

Minimal Waste

One of the standout features of the tube laser cutting machine is its efficiency in material usage. The laser cutting process produces minimal waste, as the laser beam itself is extremely narrow, ensuring that cuts are precise and the material around the cut is not affected. This significantly reduces the amount of scrap metal produced during the cutting process, saving both material costs and time spent cleaning up.

Reduced Labor Costs

With tube laser cutting, many processes are automated, meaning fewer human operators are required. This not only reduces the labor costs but also minimizes the risk of errors that could occur with manual operations. Additionally, the machine’s ability to execute complex designs without the need for extra tools means that labor time is drastically reduced.

Ⅲ.Applications of Tube Laser Cutting Machines

Automotive Industry

In the automotive industry, tube laser cutting plays a pivotal role in manufacturing complex parts such as exhaust systems, chassis components, and structural supports. The need for precision and speed in this industry makes laser cutting an invaluable tool. With tube laser cutting machines, automotive manufacturers can produce components that require exact measurements and intricate shapes.

Aerospace Manufacturing

The aerospace industry requires parts that meet strict safety and performance standards. Tube laser cutting allows for the precision needed to create everything from lightweight frames to complex brackets and supports. The accuracy and speed provided by these machines make them essential in aerospace production lines, where quality and efficiency are paramount.

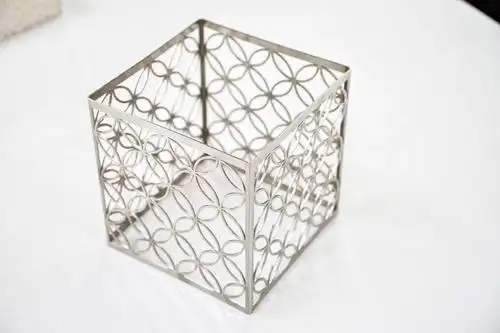

Architecture and Design

Architects and designers also benefit from the capabilities of tube laser cutting machines. Whether it’s for decorative elements, structural components, or entire facades, tube laser cutting allows for detailed, creative designs that enhance the aesthetic appeal of buildings. This technology has allowed designers to push the boundaries of what is possible with metalworking.

Medical Devices

In the medical industry, tube laser cutting machines are used to create medical devices and components such as surgical instruments, implants, and diagnostic equipment. The precision and cleanliness of the cuts are critical in ensuring that these parts meet stringent health and safety standards.

Ⅳ.The Future of Tube Laser Cutting Machines

The future of tube laser cutting machines is bright, as the technology continues to evolve. With advancements in laser beam power, machine speed, and precision, these systems will only become more efficient and versatile. As industries continue to demand higher-quality, lower-cost production, tube laser cutting will play a key role in meeting these needs.

Additionally, as the demand for customized and complex metal components increases, tube laser cutting machines will be able to meet these challenges with greater ease. Their ability to create intricate designs with minimal waste will continue to make them a go-to tool for manufacturers in a wide range of industries.

Ⅴ.Key Benefits of Tube Laser Cutting Machines:

✔High Precision: Offers exact cuts for intricate designs.

✔Efficiency: Increases production speed and reduces labor costs.

✔Cost-Effective: Minimizes waste, saving material and disposal costs.

✔Versatility: Capable of cutting a wide range of metals with varying thicknesses.

✔Automated: Reduces the need for human intervention, improving both speed and accuracy.

In the ever-demanding world of precision manufacturing, the tube laser cutting machine is an essential tool. By offering high precision, minimal waste, and greater efficiency, this machine continues to push the boundaries of what’s possible in the world of metal fabrication. Whether it’s for creating automotive parts, aerospace components, or intricate architectural designs, tube laser cutting technology is here to stay, continuing to shape the future of manufacturing.

Top Stories

-

4000W Laser Cutting Machine Guide | Essentials09 Dec 2025

4000W Laser Cutting Machine Guide | Essentials09 Dec 2025 -

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 kw laser cutting | Industrial precision guide28 Nov 2025

6 kw laser cutting | Industrial precision guide28 Nov 2025 -

Revolutionizing Industry with Steel Tube Laser Cutting Machine25 Nov 2025

Revolutionizing Industry with Steel Tube Laser Cutting Machine25 Nov 2025

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine