Новости

Лазерная режущая стальная пластина: Революционный процесс точности и эффективности

Введение: Раскрытие силы Лазерная режущая стальная пластина

В современном быстро меняющемся мире производства, достижение точность и скорость больше не являются необязательными – они являются необходимостью. Когда дело доходит до резки стальных пластин, лазерная резка выделяется как наиболее эффективный и точный метод доступный. Будь то автомобильная промышленность, строительство, или изготовление сложных деталей, лазерная резка стальных пластин предлагает непревзойденное качество, точность, и способность обрабатывать сложные формы.

Но почему лазерная резка стала популярным решением для обработки стальных листов?? В этой статье, мы углубимся в процесс лазерной резки, его преимущества, ключевые соображения, и как эта технология меняет производство в различных отраслях.

1. Что такое стальная пластина для лазерной резки?

◆ Технология лазерной резки

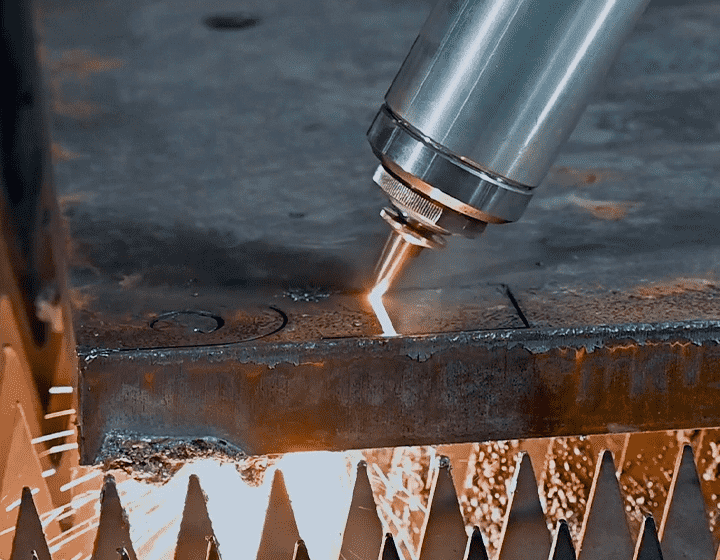

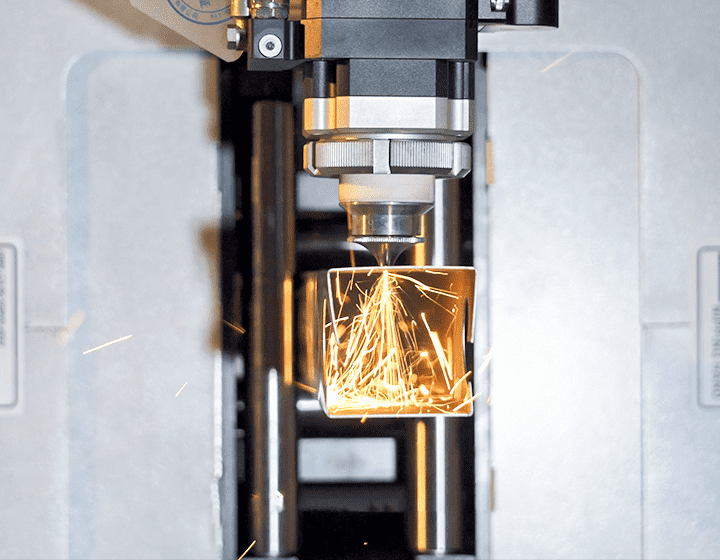

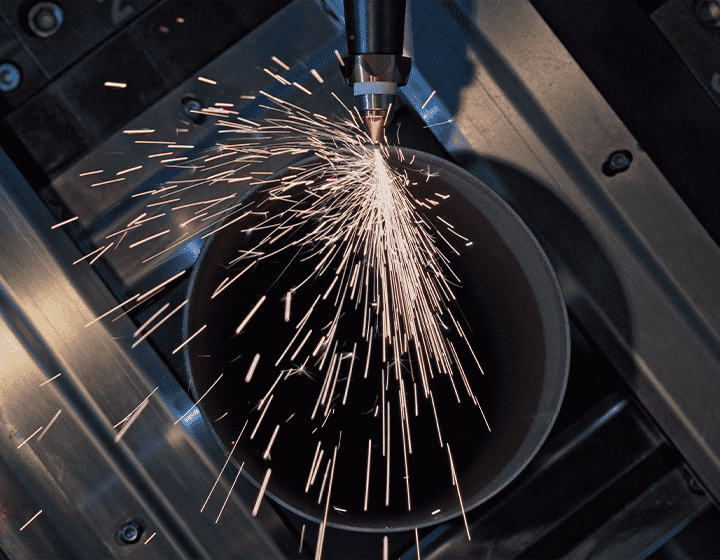

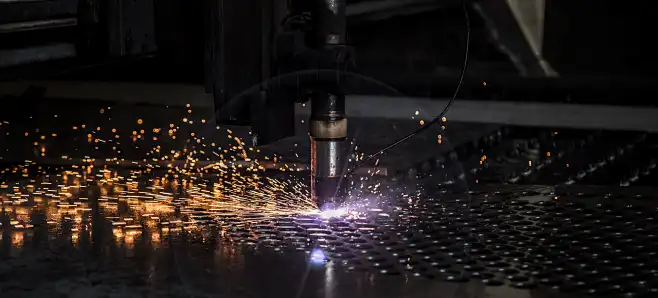

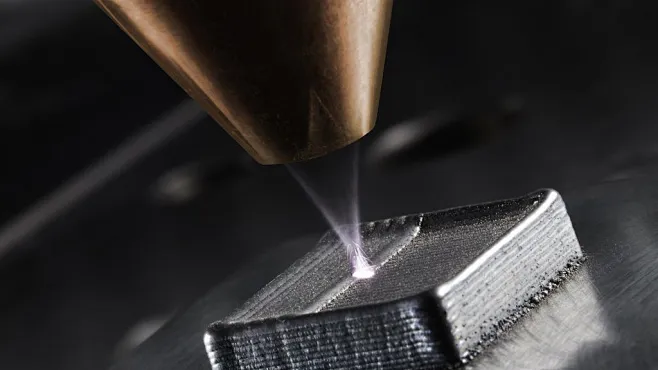

Лазерная резка стальной пластины использует сфокусированный лазерный луч для резки стали с высокой точностью. Лазер, часто волокно лазер или CO2 Лазер, генерирует луч света, который фокусируется на поверхности материала, который тает, ожоги, или испаряет сталь, в зависимости от свойств материала и настроек лазера. Результатом является чистый, Точный разрез с минимальными отходами.

◆ Как работает лазерная резка?

В типичном система лазерной резки, а ЧПУ (компьютерное числовое управление) направляет лазерный луч в определенные места на стальной пластине. Система управления станком обеспечивает резку лазером по заранее запрограммированной траектории., что делает его идеальным для сложная геометрия и сложные конструкции. Тепло лазера заставляет сталь плавиться или испаряться в точке контакта., оставляя острый и гладкий край.

★ Видео ниже поможет вам более интуитивно понять принцип работы лазерной резки стальной пластины..

2. Преимущества лазерной резки стальных пластин

◆ Высокая точность и точность

Когда дело доходит до резки стали, точность имеет решающее значение. Лазерная резка позволяет добиться чрезвычайно точные разрезы, даже для сложных форм, с такими жесткими допусками, как 0.1мм. Высокий уровень точности гарантирует идеальное прилегание деталей друг к другу., устраняя необходимость в обширной постобработке.

◆ Скорость и эффективность

Лазерная резка является одним из самые быстрые методы резки доступный. В отличие от традиционных методов резки, лазерный луч может быстро прорезать стальные пластины, резкое сокращение времени производства. Такая эффективность позволяет производителям выполнять производственные графики с высокими требованиями, сохраняя при этом высокие стандарты качества.

◆ Минимальные отходы материала

Из-за узкой ширины лазерного луча, потери материала сведены к минимуму. Разрезы настолько точны, что после них практически не остается отходов.. Это не только экономит затраты на материалы, но и делает лазерную резку более экологически чистой по сравнению с традиционными методами, которые производят больше отходов..

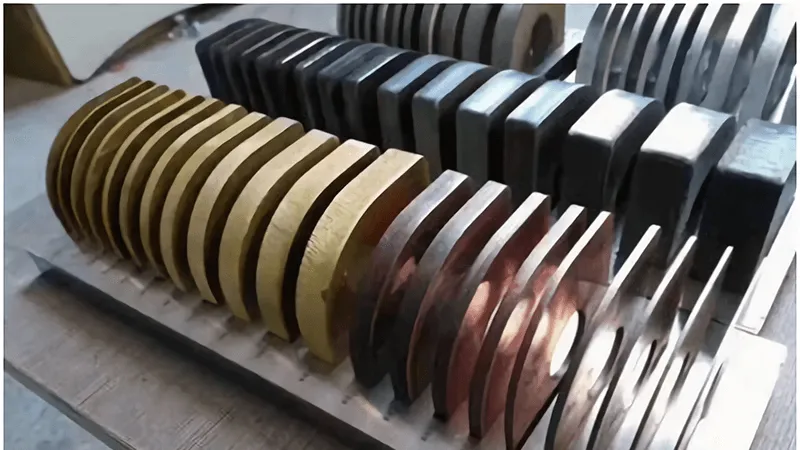

◆ Универсальность толщины стальной пластины

Лазерная резка универсальна, поскольку ее можно использовать на широком спектре стальных пластин. толщина. От тонкие листы к более толстые пластины, лазеры могут прорезать материалы, которые варьируются от 0.5мм до нескольких дюймов толщиной, позволяя предприятиям работать с разнообразной стальной продукцией для различных применений.

3. Применение лазерной резки стальных пластин

◆ Автомобильная промышленность

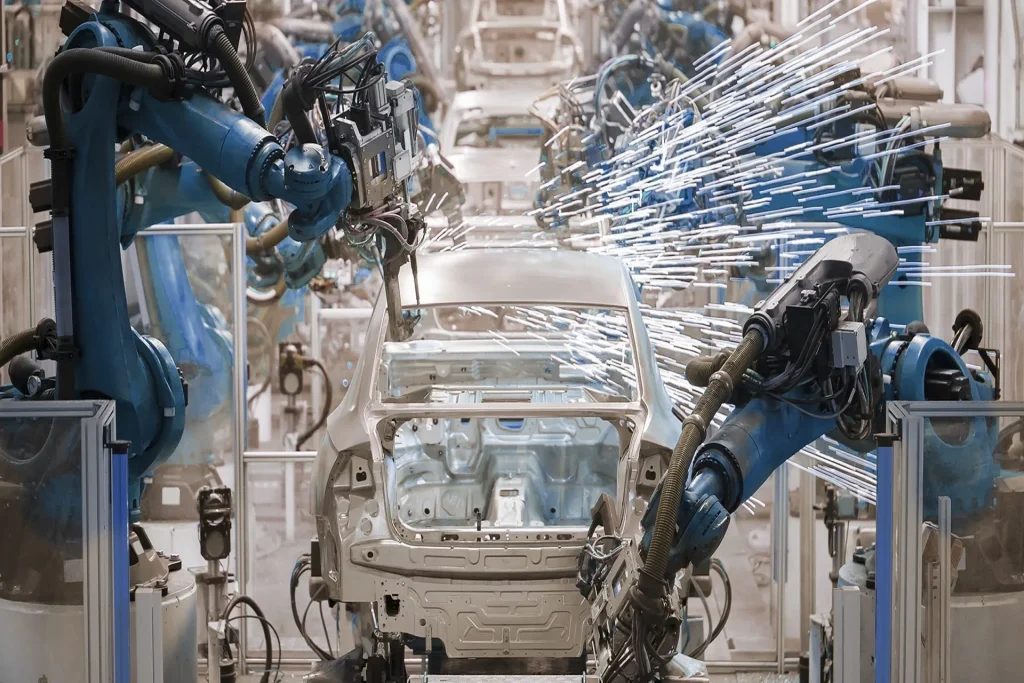

Лазерная резка играет решающую роль в автомобильная промышленность, где точность и скорость имеют первостепенное значение. Такие компоненты, как кронштейны, части тела, и каркасные конструкции часто производятся с использованием лазерной резки, обеспечение идеального соединения каждой детали при окончательной сборке.

◆ Аэрокосмическое производство

В аэрокосмической отрасли, где вес и сила имеют решающее значение, стальные пластины, вырезанные лазером используются для производства высокопрочный, легкие компоненты для самолета. Лазерная резка обеспечивает точность, необходимую для производства деталей с минимальными отходами материала, сохраняя при этом прочность, необходимую для аэрокосмической промышленности..

◆ Строительство и производство металлов

Лазерная резка стальных пластин широко используется в Изготовление металла и строительство для таких приложений, как структурные компоненты, металлические рамы, и изготовленные на заказ стальные детали. Способность резать сталь с высокой точностью позволяет производителям создавать сложные конструкции и сложные детали, которые было бы трудно получить традиционными методами..

◆ Листовая металлургия

При обработке листового металла, лазерная резка позволяет производителям изготавливать сложные Металлические детали и панели для отраслей промышленности, начиная от Электроника к техника. Чистый разрез и минимальная деформация делают лазерную резку превосходным методом производства высококачественных деталей..

◆ Художественные и декоративные применения

Лазерная резка предназначена не только для промышленного использования — она также широко используется в декоративный и художественные приложения. Дизайнеры используют стальные пластины, вырезанные лазером создать индивидуальный дизайн, стены, и декоративные панели, использование возможностей машины для выполнения детальных и сложных разрезов.

4. Ключевые факторы, которые следует учитывать при выборе станка для лазерной резки стальных пластин

◆ Мощность лазера

The мощность лазера является одним из важнейших факторов при выборе машины. Для стальных пластин, Мощность лазера обычно составляет от 500W до 6000 Вт. Лазеры большей мощности идеально подходят для резки толстых листов., тогда как для более тонких материалов достаточно машин меньшей мощности.

◆ Скорость резки

Станки лазерной резки известны своими скорость, но это зависит от толщины материала, тип, и мощность лазера. Важно выбрать машину, которая уравновешивает скорость резания с точность для удовлетворения производственных потребностей.

◆ Производительность погрузочно-разгрузочных работ

Стальные пластины бывают разных размеров., поэтому очень важно выбрать машину, которая сможет обрабатывать пластины того размера, с которыми вы работаете.. Убедитесь, что сокращение размера кровати соответствует вашим производственным потребностям.

◆ Функции автоматизации

Многие современные станки для лазерной резки оснащены автоматизированные функции такой как погрузка и разгрузка материала, частичное вложение, и Оптимизация пути резки. Эти функции могут повысить производительность, уменьшить человеческую ошибку, и обеспечить более быстрое время обработки.

5. Будущее лазерной резки стальных пластин

Как Лазерная технология резания продолжает развиваться, мы можем ожидать еще более совершенных машин, которые предлагают большая точность, Более быстрая скорость резки, и более низкие эксплуатационные расходы. Такие инновации, как Оптимизация, управляемая ИИ, мониторинг процесса в режиме реального времени, и более высокая энергоэффективность ожидается, что они еще больше расширят возможности лазерной резки..

С растущий спрос на точность, роль лазерная резка стальных пластин будет продолжать расширяться, позволяя отраслям удовлетворять все более сложные производственные требования. Будь то для промышленное применение, Автомобильное производство, или художественный дизайн, лазерная резка предлагает идеальное решение для высококачественной, эффективная резка стальных листов.

Включение Лазерная технология резания в вашу деятельность может значительно улучшить вашу производственные возможности, уменьшить отходы, и повысить общую эффективность. Независимо от того, производите ли вы автомобильные детали, аэрокосмические компоненты, или нестандартные металлические конструкции, лазерная резка стальных пластин гарантирует, что вы соответствуете самым высоким стандартам качества и точности. Понимая преимущества и особенности лазерной резки, вы можете принять обоснованное решение об интеграции этой мощной технологии в ваш бизнес.

Главные новости

-

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025 -

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025 -

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025 -

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025 -

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина